Extreme ultraviolet lithography light source collection and illumination system

A technology for extreme ultraviolet lithography and lighting systems, applied in the field of extreme ultraviolet lithography light source collection and lighting systems, can solve the problems of short axial distance, difficult processing of hyperbolic reflective surfaces, and no practical approval, and achieve easy Processing and assembly, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] combine figure 1 and figure 2 , an embodiment of the present invention is given, mainly as a further detailed description of the present invention, rather than limiting the scope of the present invention.

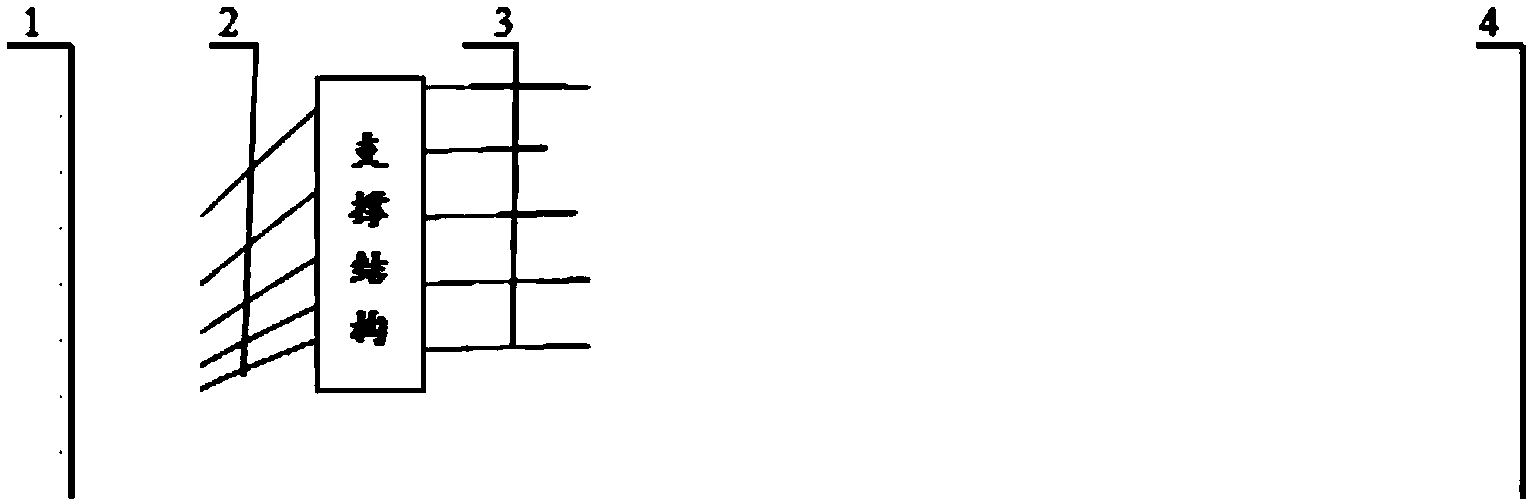

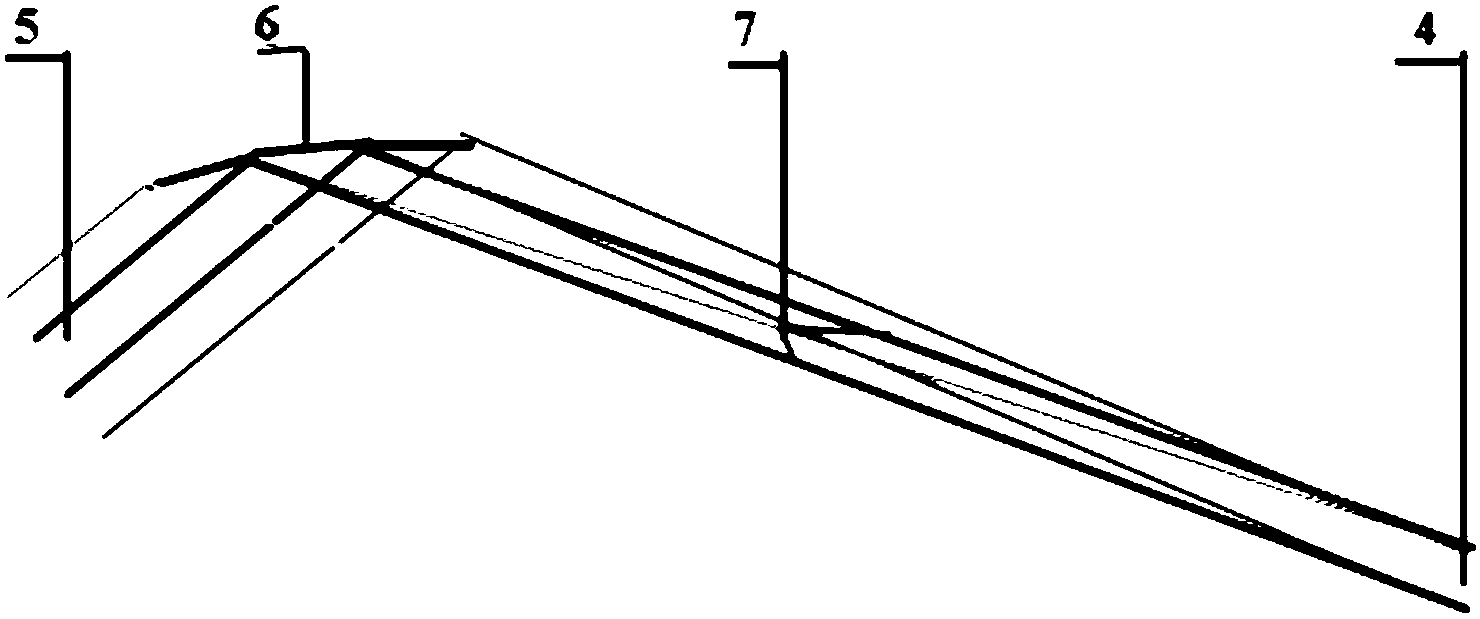

[0028] Such as figure 1 As shown, the extreme ultraviolet lithography light source collection and illumination system provided in this embodiment includes a light source 1 , a front reflector group 2 , a rear reflector group 3 and an illumination spot 4 . The illumination aperture angle of the mask plate should be matched with the object space aperture angle of the projection system. Based on this condition, it can be preliminarily determined that the image space numerical aperture of the light source collection and illumination system in this embodiment is 0.3 (approximately the system rear end surface For the half angle radian value of the illumination spot 4). If the light source is a laser plasma light source (LPP), because the size of the plasma is very smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com