Distributing plate for carbon fiber spinning and distributing assembly thereof

A distribution plate and spinning technology, which is applied in the field of fiber spinning and processing, can solve the problems such as the overall performance decline of the tow, the easy occurrence of broken filaments, and the impact on the process, so as to achieve the effect of retaining the runoff area, facilitating processing and assembly, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the following detailed description is not considered to limit the present invention.

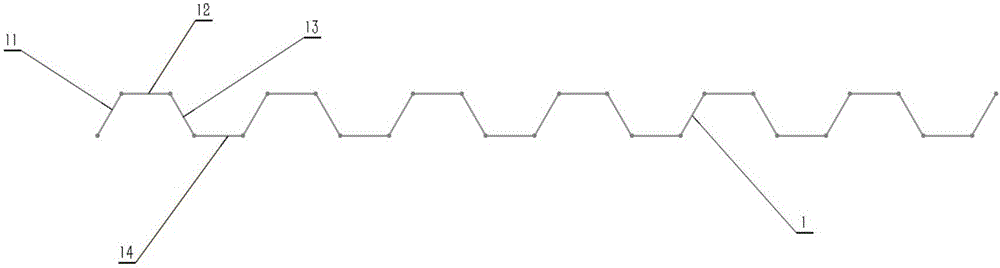

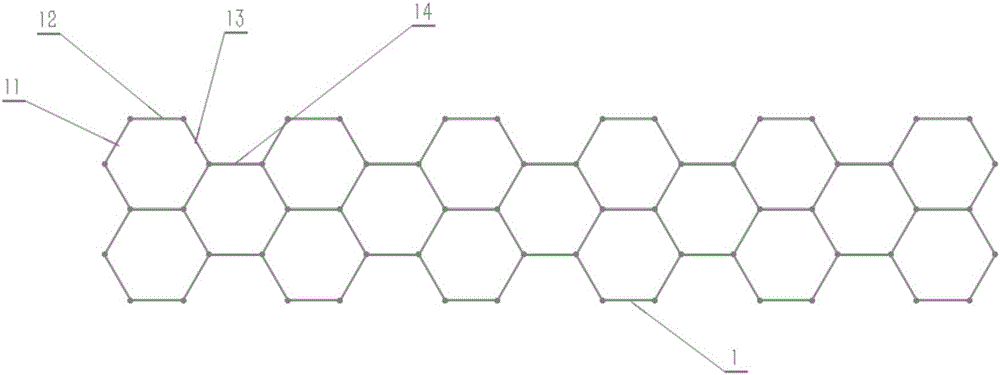

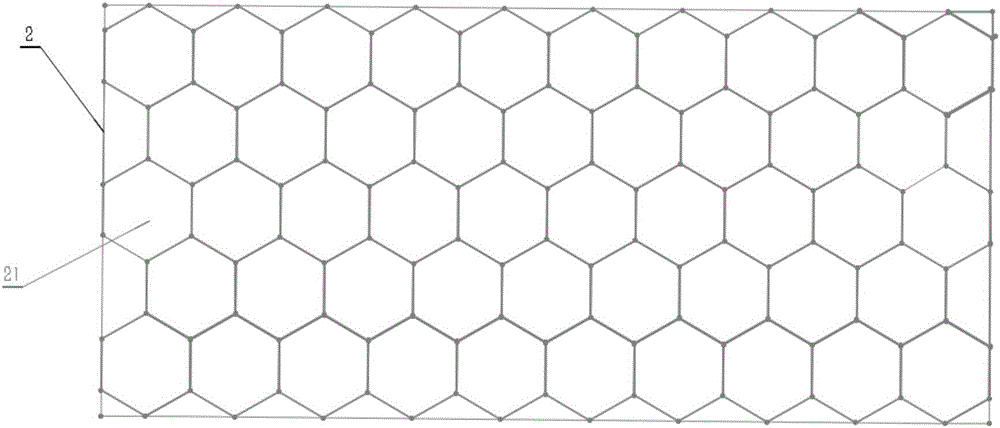

[0027] The distribution plate provided by the present invention is composed of several slats 1 and plate frames 2 . figure 1 It is a schematic diagram of the front view structure of the distribution board slats in a preferred solution of the present invention. From figure 1 It can be seen that the slat 1 is a wave structure formed by multiple bending. In actual operation, a strip metal sheet with sufficient width can be selected according to actual needs, and formed by multiple bending. The whole slat is formed by connecting end to end of a crest and trough structural unit. Each crest and trough unit consists of a bending surface I 11 bent upwards obliquely, a horizontal connection surface I 12 connected to the end of the bending surface I 11, and an obliquely downward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com