A kind of bioactive porous hybrid carbon nanofiber material and preparation method thereof

A technology of carbon nanofibers and bioactivity, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, prosthesis, etc., can solve the application requirements that cannot meet the high bioactivity of carbon nanofibers, reduce the activity of bioactive particles, and the structure of pores is not easy Control and other issues to achieve excellent biological activity, accelerated release speed, and accelerated formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

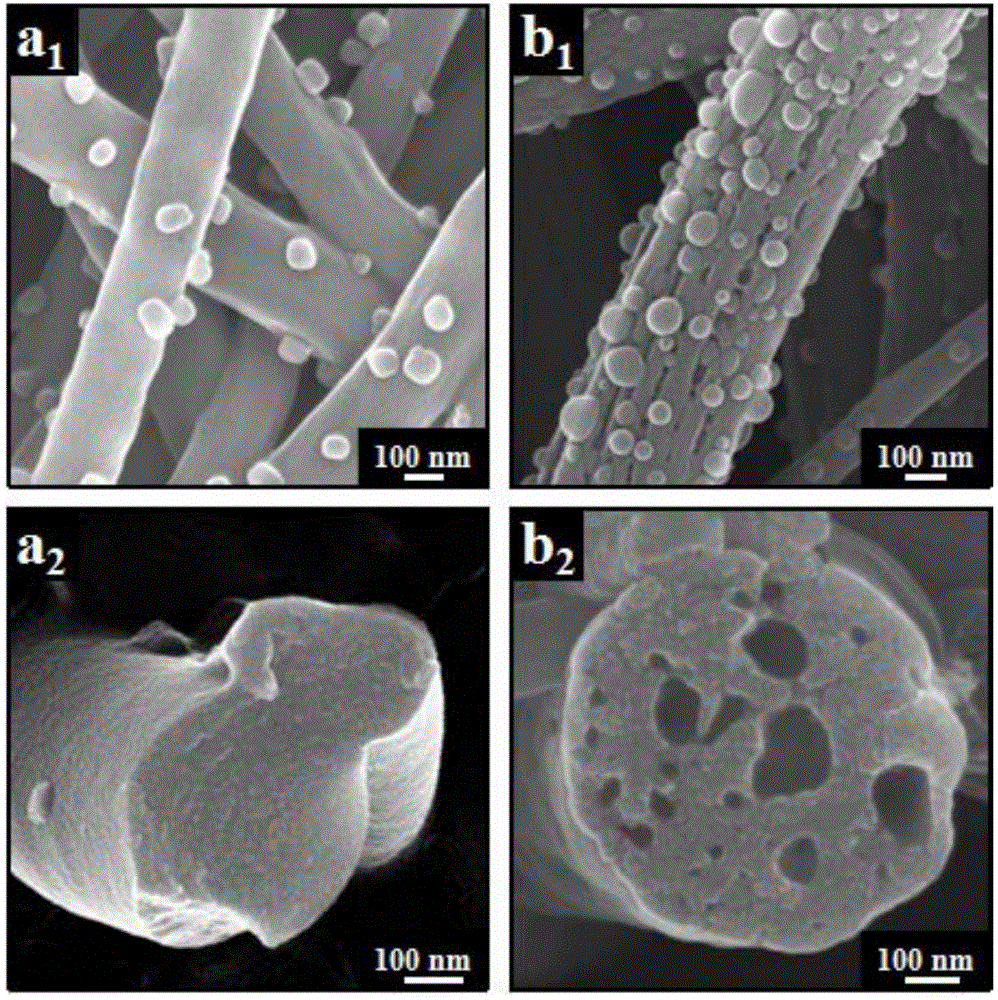

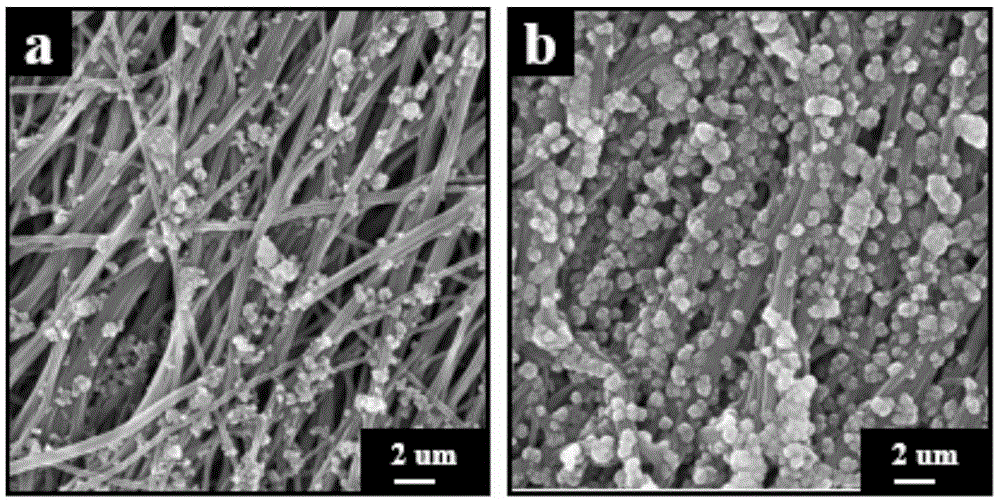

Embodiment 1

[0025] Using calcium nitrate tetrahydrate as the calcium source, triethyl phosphate as the phosphorus source, and tetraethyl orthosilicate as the silicon source, the three are miscible to obtain a bioactive glass sol-gel solution, and its mass in the spinning solution The percentage is 5%. Polyacrylonitrile and polylactic acid are miscible in nitrogen-nitrogen dimethylformamide at a mass ratio of 2 / 1, and a uniform and stable solution is obtained by ultrasonication in a 70°C water bath, and then the bioactive glass sol-gel solution is added From the above solution, the spinning solution was prepared by ultrasonic aging for 4 days, and the nascent nanofiber membrane was prepared by electrospinning.

[0026] Cut the nascent nanofiber membrane to a suitable size, fix both ends with clamps, and apply a constant force at the lower end of the clamps, then hang it in a pre-oxidation furnace for thermal drawing and pre-oxidation process of heating up in stages, heating at 5°C / min Hea...

Embodiment 2

[0028]Calcium nitrate tetrahydrate was used as the calcium source, and triethyl phosphate was used as the phosphorus source. The α-tricalcium phosphate sol-gel solution was prepared by mixing the two, and its mass percentage in the spinning solution was 10%. Polyacrylonitrile and polylactic acid are miscible in nitrogen-nitrogen dimethylformamide at a mass ratio of 2 / 1, and a uniform and stable solution is obtained by ultrasonication in a water bath at 70°C, and then α-tricalcium phosphate sol-gel The solution was added to the above solution, and the spinning solution was prepared by ultrasonic aging for 4 days, and the primary nanofiber film was prepared by electrospinning.

[0029] Cut the nascent nanofiber membrane to a suitable size, fix both ends with clamps, and apply a constant force at the lower end of the clamps, then hang it in a pre-oxidation furnace for thermal drawing and pre-oxidation process of heating up in stages, heating at 5°C / min Heat at 100°C for 10 minute...

Embodiment 3

[0031] Calcium nitrate tetrahydrate was used as the calcium source, and triethyl phosphate was used as the phosphorus source, and the two were mixed to obtain a β-tricalcium phosphate sol-gel solution, and its mass percentage in the spinning solution was 8%. Polyacrylonitrile and polylactic acid are miscibly dissolved in nitrogen-nitrogen dimethylformamide at a mass ratio of 2 / 1, and a uniform and stable solution is obtained by ultrasonication in a water bath at 70°C, and then β-tricalcium phosphate sol-gel The solution was added to the above solution, and the spinning solution was prepared by ultrasonic aging for 5 days, and the nascent nanofiber membrane was prepared by electrospinning.

[0032] Cut the nascent nanofiber membrane to a suitable size, fix both ends with clamps, and apply a constant force at the lower end of the clamps, then hang it in a pre-oxidation furnace for thermal drawing and pre-oxidation process of heating up in stages, heating at 5°C / min Heat at 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com