Rigid plastic bridge and preparation method thereof

A technology of rigid plastic and bridge, applied in the field of rigid plastic bridge and its preparation, can solve the problems of high production cost, poor use effect, large amount of formula addition, etc., and achieves good flame retardant performance, improved strength, and improved related performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

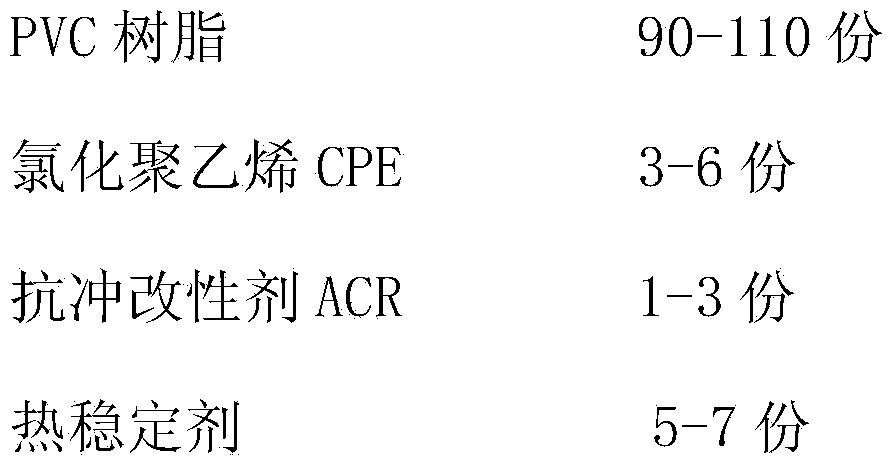

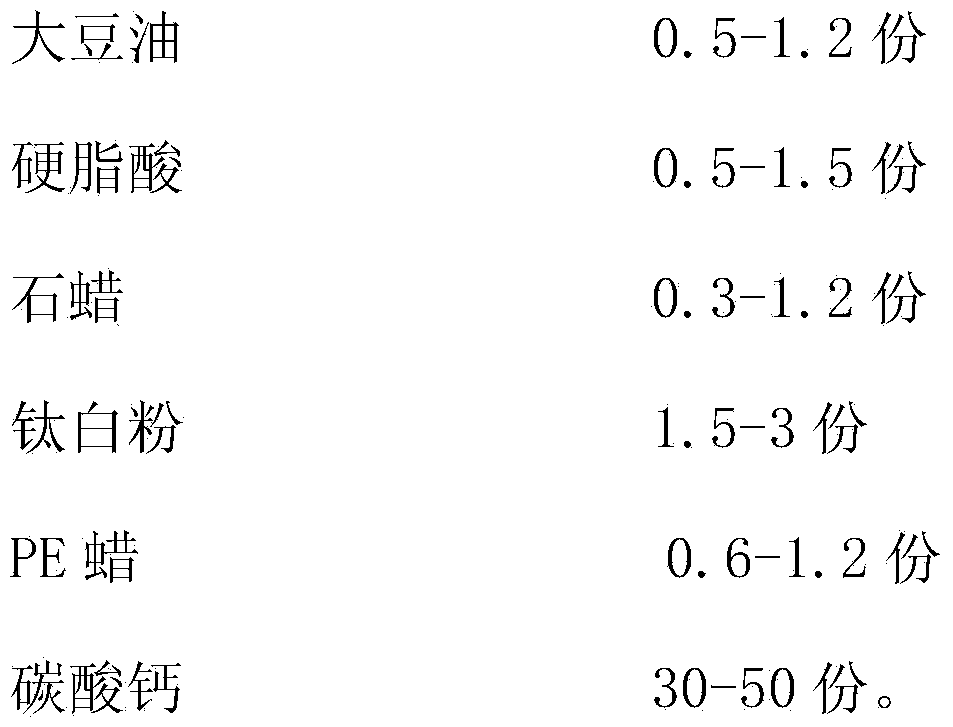

Method used

Image

Examples

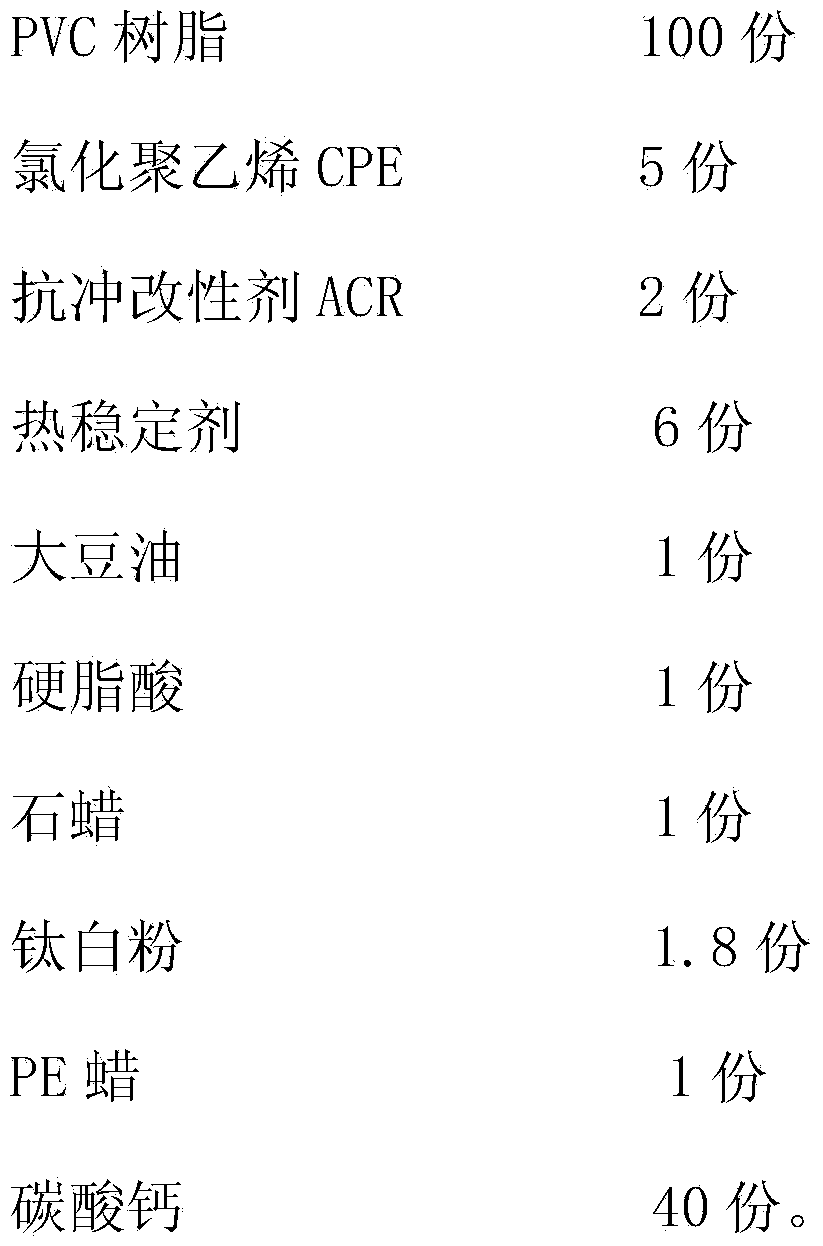

example 1

[0026] A kind of rigid plastic bridge, comprises shell, and its preparation method is:

[0027] 1. Preparation of heat stabilizer: 18 parts by weight of zinc-magnesium-aluminum ternary hydrotalcite, 12 parts of magnesium-aluminum binary hydrotalcite, 8 parts of calcium dimer acid, 8 parts of zinc dimer acid, 36 parts of zinc stearate 12 parts of dipentaerythritol glutarate, 3 parts of epoxidized soybean oil, 2 parts of dibenzoylmethane and 5 parts of maleic anhydride are added to the mixer while heating and stirring, and the heat stabilizer is obtained after stirring for 1.5-2 hours ;

[0028] 2. 100 parts by weight of PVC resin, 5 parts of chlorinated polyethylene CPE, 2 parts of impact modifier ACR, 6 parts of heat stabilizer, 1 part of soybean oil, 1 part of stearic acid, 1 part of paraffin, titanium dioxide Add 1.8 parts, 1 part of PE wax, and 40 parts of calcium carbonate into the mixer for stirring and mixing. During the mixing process, the mixer heats the raw materials...

example 2

[0031] A kind of rigid plastic bridge, comprises shell, and its preparation method is:

[0032] 1. Preparation of heat stabilizer: 18 parts by weight of zinc-magnesium-aluminum ternary hydrotalcite, 12 parts of magnesium-aluminum binary hydrotalcite, 8 parts of calcium dimer acid, 8 parts of zinc dimer acid, 36 parts of zinc stearate 12 parts of dipentaerythritol glutarate, 3 parts of epoxidized soybean oil, 2 parts of dibenzoylmethane and 5 parts of maleic anhydride are added to the mixer while heating and stirring, and the heat stabilizer is obtained after stirring for 1.5-2 hours ;

[0033] 2. 100 parts by weight of PVC resin, 3 parts of chlorinated polyethylene CPE, 1 part of impact modifier ACR, 5.5 parts of heat stabilizer, 0.6 part of soybean oil, 0.8 part of stearic acid, 1 part of paraffin, titanium dioxide Add 2 parts, 0.8 parts of PE wax, and 35 parts of calcium carbonate into the mixer for stirring and mixing. During the mixing process, the mixer heats the raw mat...

example 3

[0036] A kind of rigid plastic bridge, comprises shell, and its preparation method is:

[0037] 1. Preparation of heat stabilizer: 18 parts by weight of zinc-magnesium-aluminum ternary hydrotalcite, 12 parts of magnesium-aluminum binary hydrotalcite, 8 parts of calcium dimer acid, 8 parts of zinc dimer acid, 36 parts of zinc stearate 12 parts of dipentaerythritol glutarate, 3 parts of epoxidized soybean oil, 2 parts of dibenzoylmethane and 5 parts of maleic anhydride are added to the mixer while heating and stirring, and the heat stabilizer is obtained after stirring for 1.5-2 hours ;

[0038] 2. 100 parts by weight of PVC resin, 4 parts of chlorinated polyethylene CPE, 1.5 parts of impact modifier ACR, 6 parts of heat stabilizer, 0.8 part of soybean oil, 1.2 parts of stearic acid, 0.8 part of paraffin, Add 1.5 parts of titanium dioxide, 0.6 parts of PE wax, and 42 parts of calcium carbonate into the mixer for stirring and mixing. During the mixing process, the mixer heats th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com