Micro injection molding machine

An injection molding machine and micro technology, which is applied in the field of micro injection molding machines, can solve the problems of difficult control of the molding quality of parts and high requirements for the design of runner balance, and achieves a small footprint, easy mold runner balance, and easy control of molding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

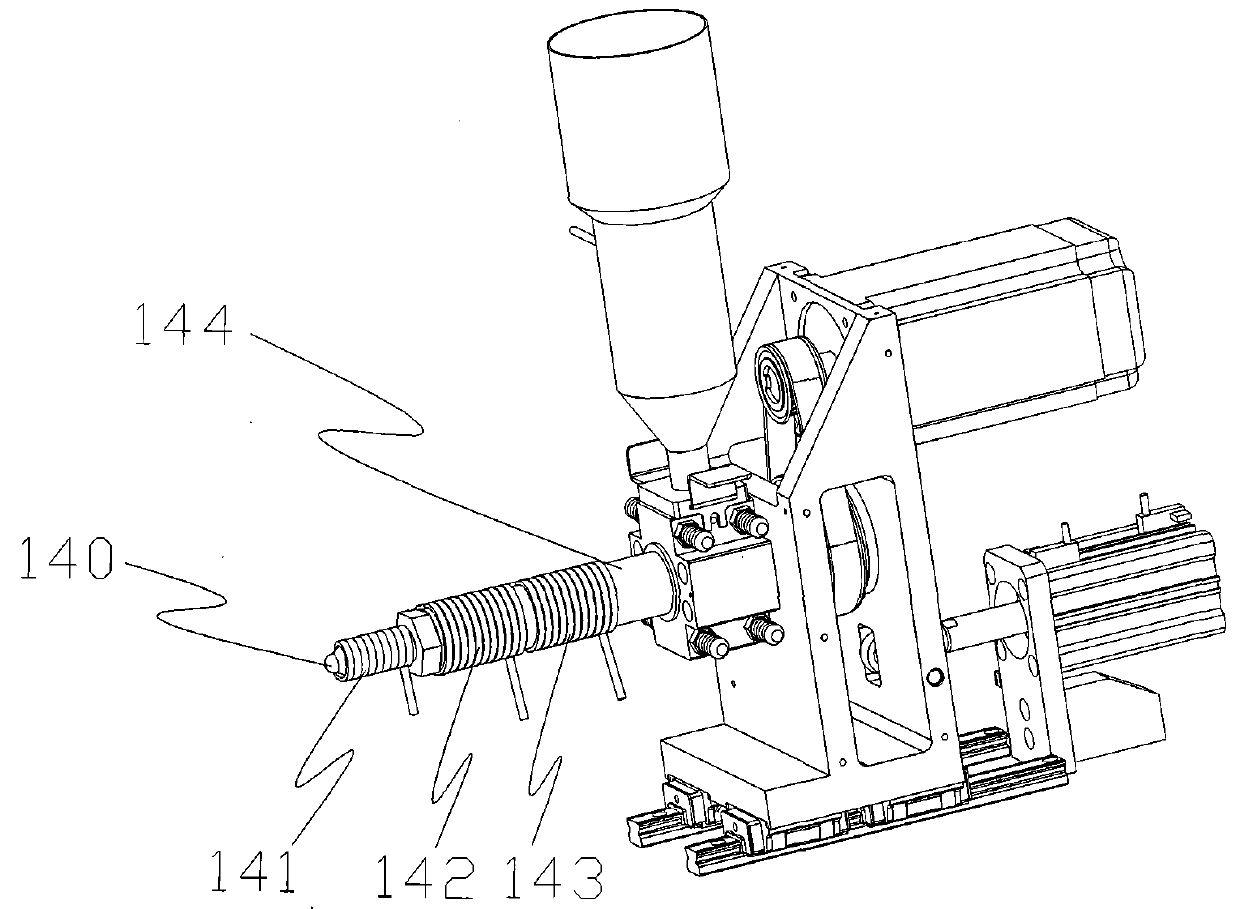

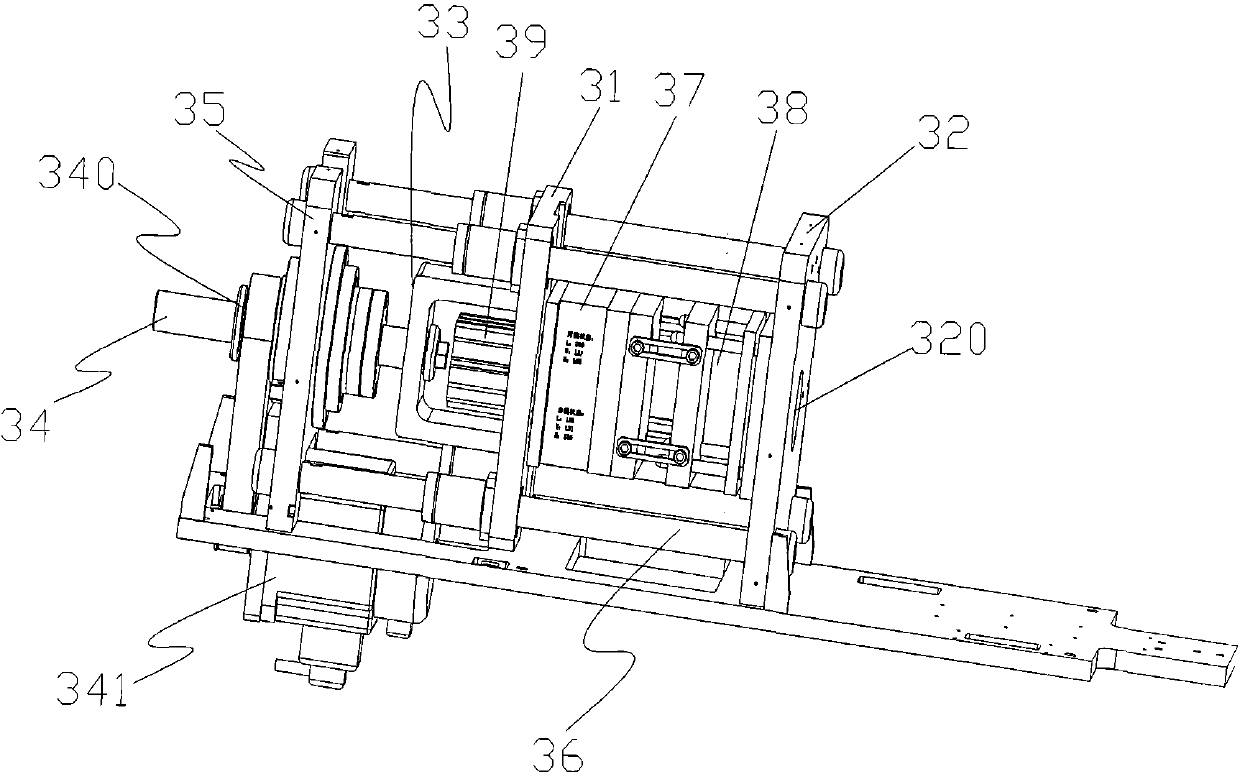

[0026] refer to figure 1 , the present invention provides a micro-injection molding machine, extrusion device 1, which is the core part of the injection molding machine, completes the plasticization of plastic raw materials and injects the plasticized plastic into the mold cavity; mold clamping device 3, which It is the core part of the injection molding machine. The mold locking of the micro injection molding machine adopts the two-platen mold locking method, which mainly realizes the opening and closing between the front mold and the rear mold; the control cabinet, which is the circuit control part inside, controls the operation of the entire equipment, for The core control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com