Method for preparing superconducting joint of Bi-2212 wire rod

A bi-2212, superconducting joint technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of the overall performance of the wire and strip, affecting the effect of superconducting joints, poor performance of superconducting joints, etc. , to achieve the effect of low manufacturing cost, improved connection and high current-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

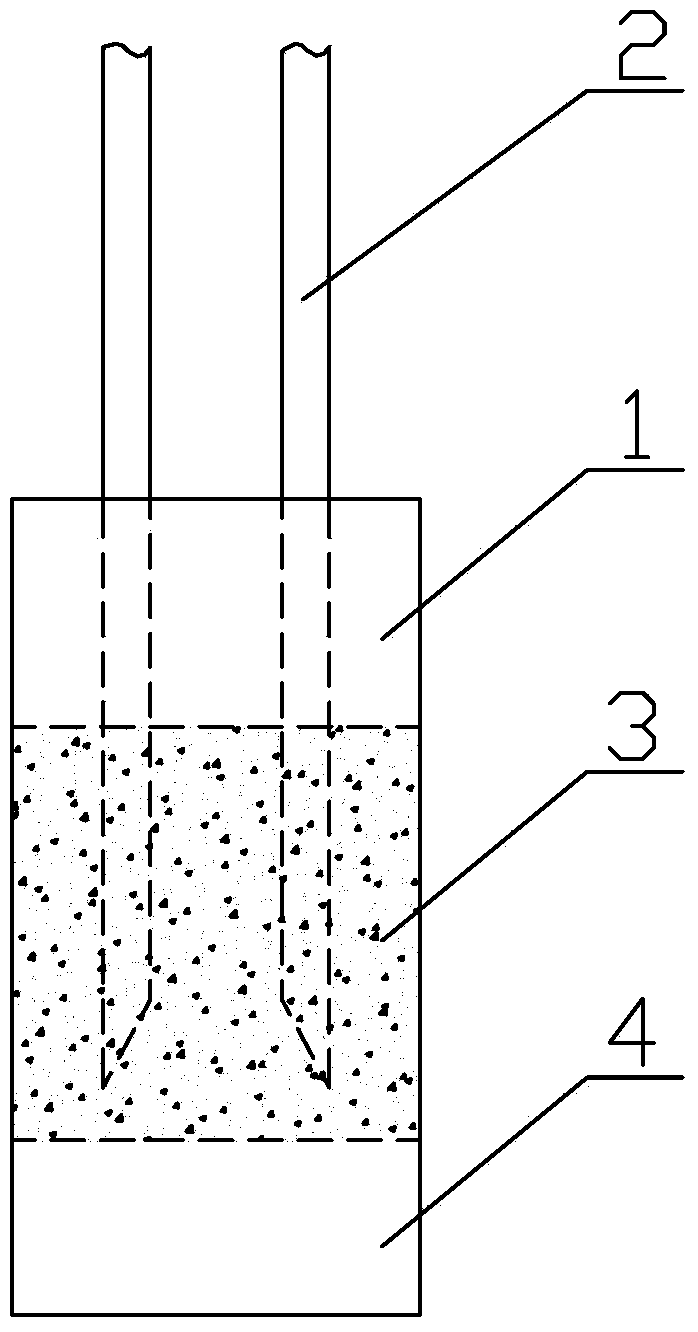

Image

Examples

Embodiment 1

[0031] Step 1. Use two Bi-2212 wires with a diameter of 1.25mm, clean the ends of the Bi-2212 wires to be connected, and then polish the cleaned ends with metallographic sandpaper, and finally form an inclination at the end of the Bi-2212 wires The polished surface; the angle between the polished surface and the length direction of the Bi-2212 wire is 30 degrees;

[0032] Step 2, placing the polished surface of the Bi-2212 wire rod polished and polished in step 1 in a corrosion solution for 20 minutes; the corrosion solution is made by uniformly mixing ammonia water, hydrogen peroxide and methanol according to a volume ratio of 30:10:100; In the corrosion process, control the length direction of the Bi-2212 wire rod to be perpendicular to the liquid surface of the corrosion solution, and the polished surface of the Bi-2212 wire rod is located below the liquid surface of the corrosion solution; the ammonia water, hydrogen peroxide and methanol are chemically pure reagents;

[0...

Embodiment 2

[0037]Step 1. Use two Bi-2212 wires with a diameter of 1.5mm, clean the ends of the Bi-2212 wires to be connected, and then polish the cleaned ends with metallographic sandpaper, and finally form a slope at the end of the Bi-2212 wires The polished surface; the angle between the polished surface and the length direction of the Bi-2212 wire is 40 degrees;

[0038] Step 2, placing the polished surface of the Bi-2212 wire rod polished in step 1 in a corrosion solution for 10 minutes; the corrosion solution is made by uniformly mixing ammonia water, hydrogen peroxide and methanol according to a volume ratio of 50:20:100; In the corrosion process, control the length direction of the Bi-2212 wire rod to be perpendicular to the liquid surface of the corrosion solution, and the polished surface of the Bi-2212 wire rod is located below the liquid surface of the corrosion solution; the ammonia water, hydrogen peroxide and methanol are chemically pure reagents;

[0039] Step three, such ...

Embodiment 3

[0043] Step 1. Use two Bi-2212 wires with a diameter of 0.8mm, clean the ends of the Bi-2212 wires to be connected, then polish the cleaned ends with metallographic sandpaper, and finally form a slope at the end of the Bi-2212 wires The polished surface; the angle between the polished surface and the length direction of the Bi-2212 wire is 30 degrees;

[0044] Step 2, placing the polished surface of the Bi-2212 wire rod polished in step 1 in a corrosion solution for 10 minutes; the corrosion solution is made by uniformly mixing ammonia water, hydrogen peroxide and methanol according to a volume ratio of 20:20:100; In the corrosion process, control the length direction of the Bi-2212 wire rod to be perpendicular to the liquid surface of the corrosion solution, and the polished surface of the Bi-2212 wire rod is located below the liquid surface of the corrosion solution; the ammonia water, hydrogen peroxide and methanol are chemically pure reagents;

[0045] Step three, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com