Production method of aluminium deoxidation 20 Cr steel

A production method and technology for aluminum deoxidation, applied in the field of steelmaking, can solve the problems of poor pourability and difficulty of continuous casting of aluminum deoxidized 20Cr steel, and achieve the effects of increasing the pulling speed, improving the pourability and reducing the inclusions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with specific embodiments.

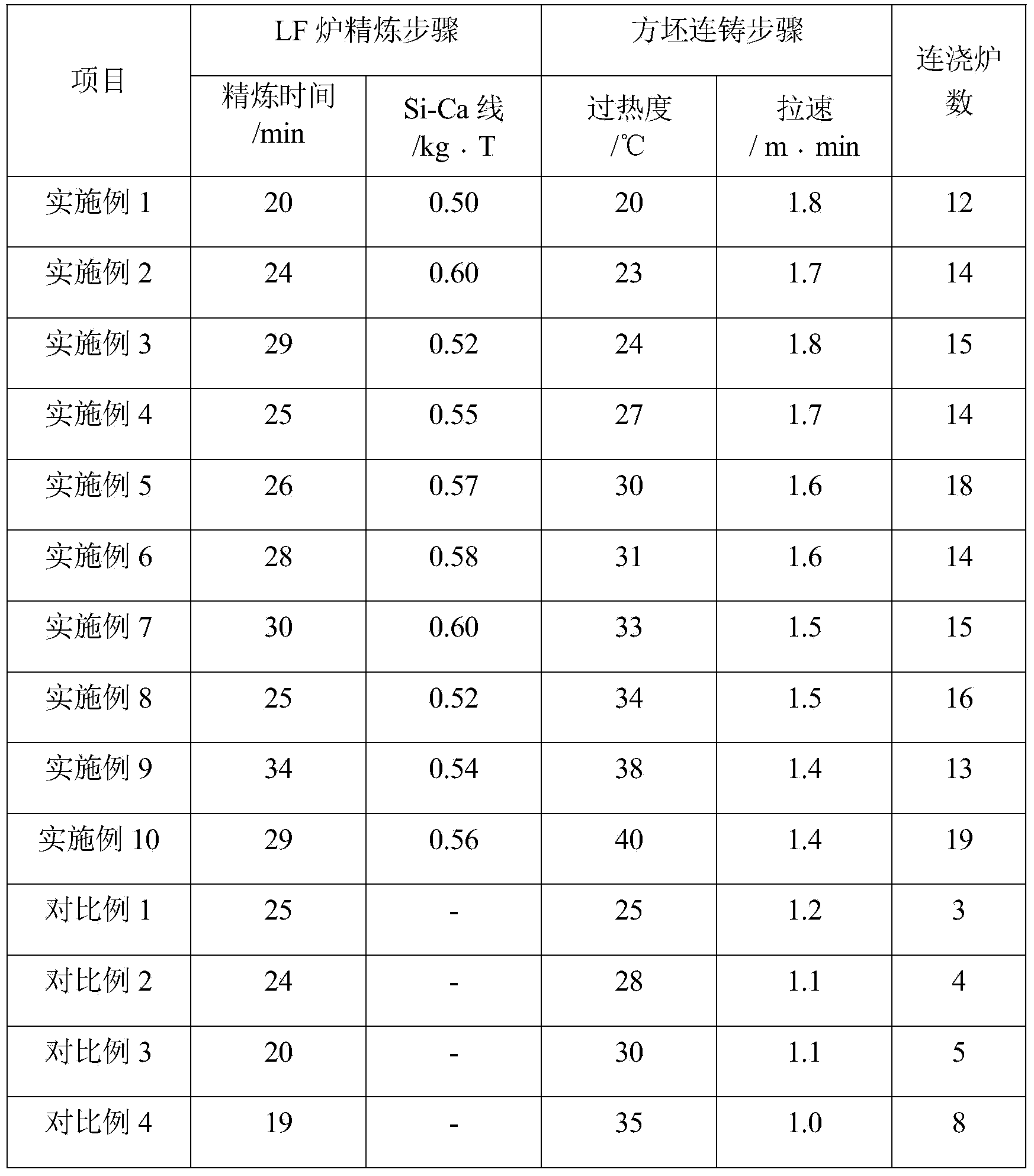

[0011] The production methods of the 20Cr steel in the embodiment of the present invention and the comparative example all include the steps of molten iron desulfurization, converter / electric furnace smelting, argon blowing in an argon station, LF furnace refining and billet continuous casting. The only difference lies in the process of LF furnace refining and billet continuous casting steps. Among them, the refining steps of the LF furnace in Examples 1 to 10 are as follows: argon is blown at the bottom of the LF furnace throughout the process, and the refining time is ≥ 20 minutes. The molten steel is fed into the Si-Ca line at 0.5 kg to 0.6 kg per ton of steel 3 to 5 minutes before the lifting of the LF furnace. After soft blowing for 3-4 minutes, lift the ladle to the continuous casting machine for continuous casting; the billet continuous casting steps are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com