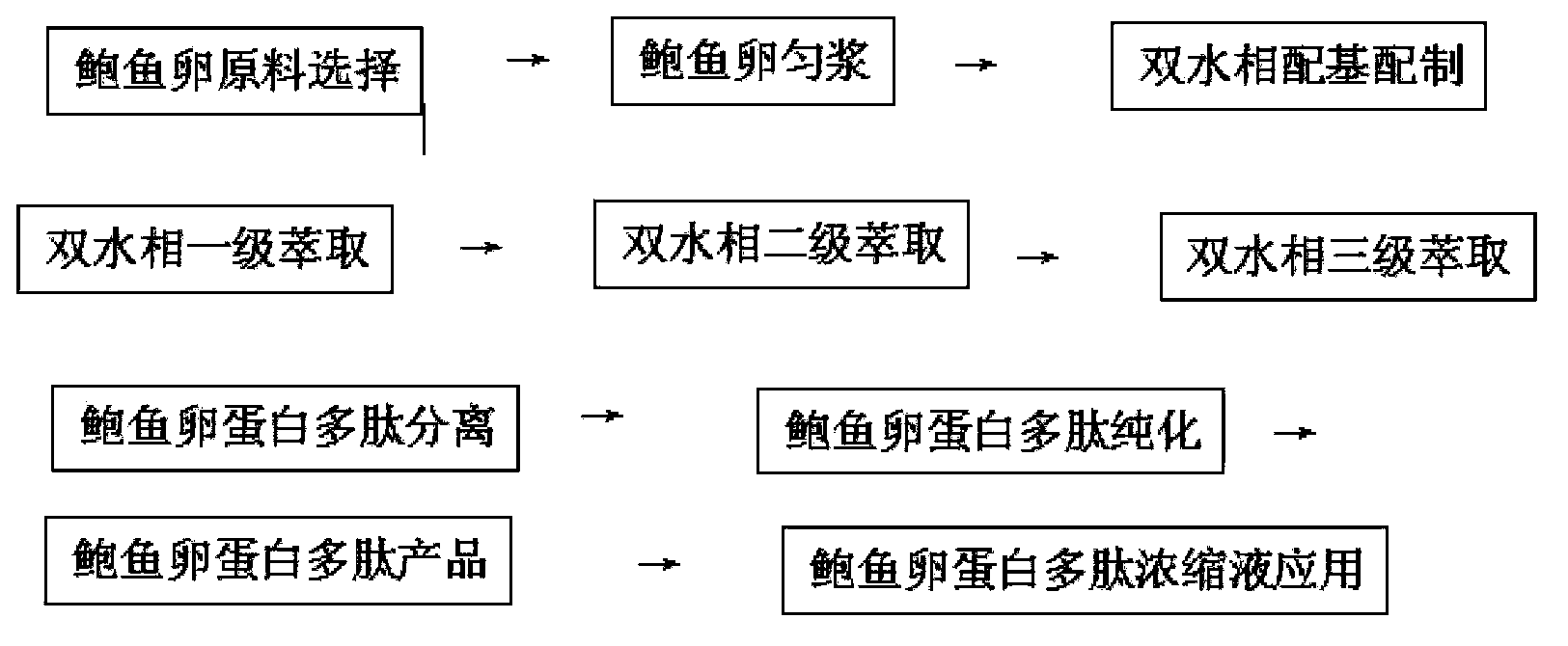

Method for two-aqueous phase extraction of abalone egg albumin polypeptide concentrated liquor

A technology of egg protein polypeptide and two-phase water, which is applied in the field of separation and purification of biologically active substances, can solve problems such as waste of abalone nutritional resources, and achieve the effects of saving extraction time, strong binding, and short phase separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

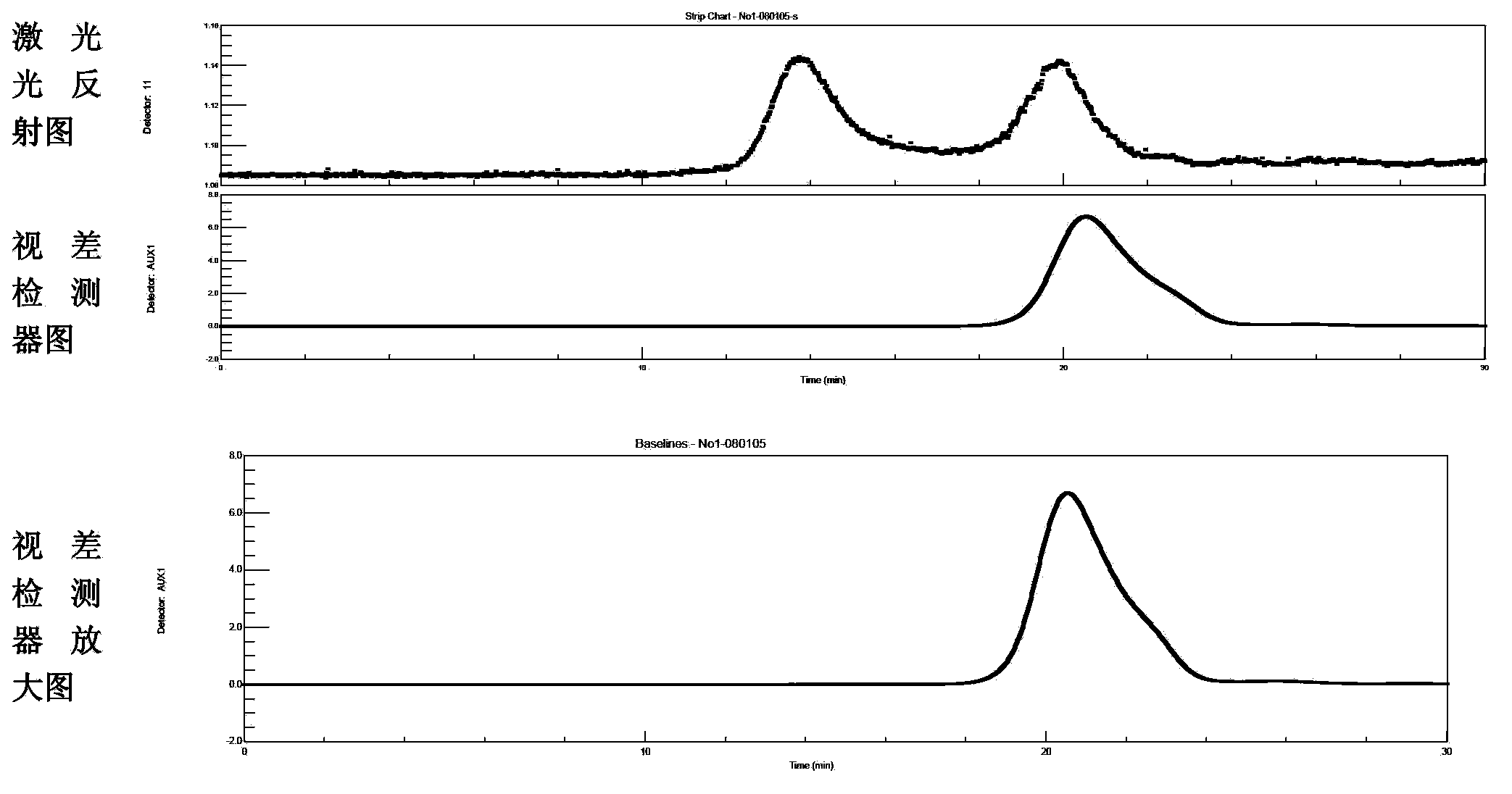

Examples

Embodiment 1

[0042] Take 150kg of fresh abalone eggs and clean them with edible water, then use a stainless steel colloid mill to crush the abalone eggs, input them into a high-shear emulsifier (manufactured by Wenzhou Haichuan Machinery Co., Ltd.), add 150kg of edible water, and stir evenly. 300kg of abalone roe homogenate was produced by high-shear emulsification at 3000r / min, and filtered through 100 mesh to obtain 300kg of abalone roe homogenate with a concentration of 18% for later use. Choose polyethylene glycol (PEG8000) 21.6kg, drinking water (H 2 O) 98.4kg, using a 600L stainless steel compound tank (manufactured by Wenzhou Haichuan Machinery Co., Ltd.) to stir and mix evenly to make {A} the upper phase of the first group of ligands is 120kg, and the solute (mass fraction) concentration is 18%. Then select NaCl, 19.2kg., H 2 O100.8kg. Prepare {A} first group of ligand lower phase 120kg, solute (mass fraction) concentration 16%. Start the thick slurry pump (manufactured by Wenzh...

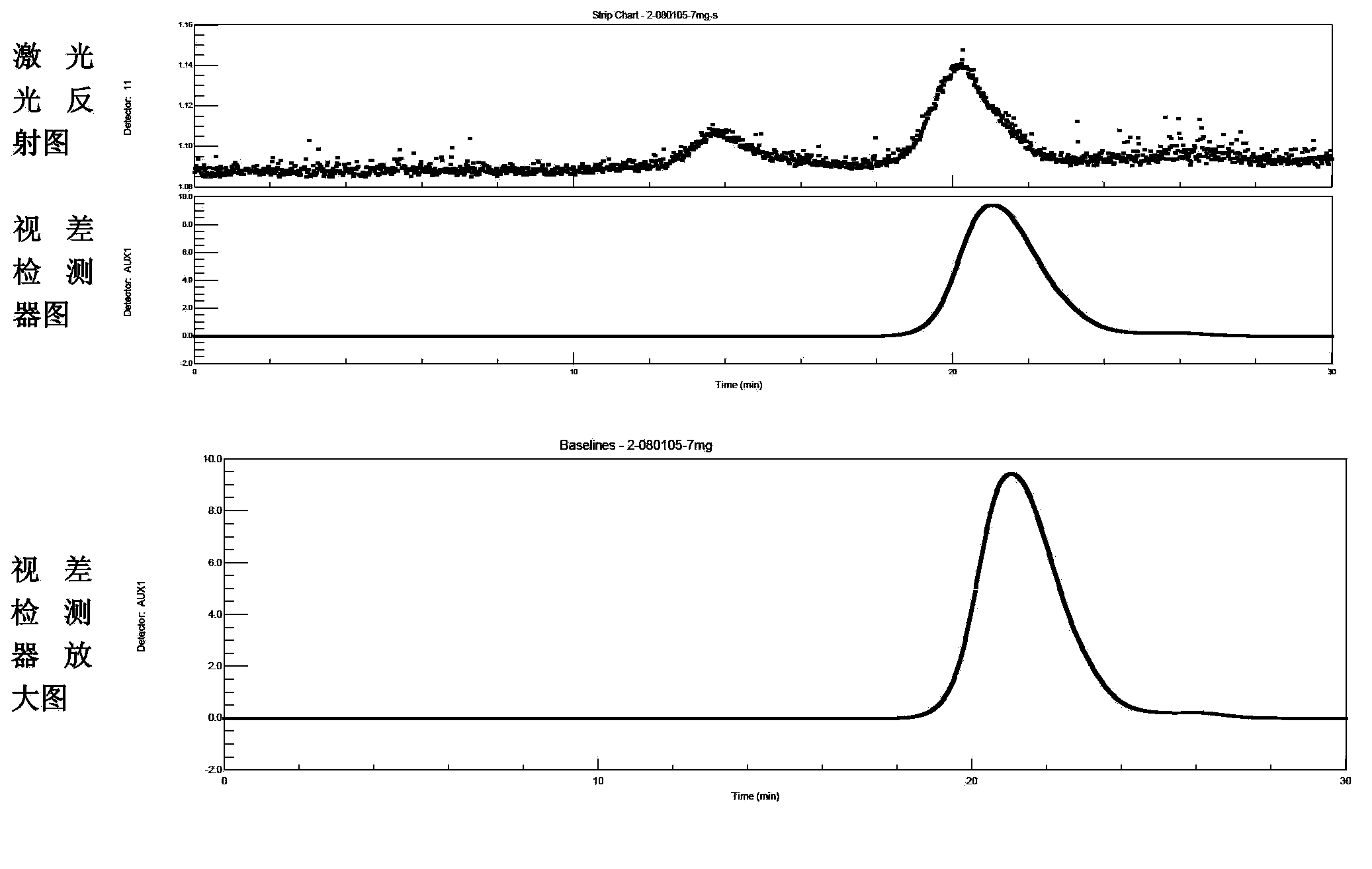

Embodiment 2

[0048] Embodiment 2 differs from Embodiment 1 in that:

[0049] 1. Abalone roe homogenate;

[0050] Prefabricated abalone roe homogenate, choose frozen abalone roe 100kg water 73.6%, protein content 23.3% as raw material. After cleaning, crush, add 100kg of pure water according to the mass ratio of abalone roe, and make 200kg of homogenate through a 3000r / min high-shear emulsifier (manufactured by Wenzhou Haichuan Machinery Co., Ltd.), and filter through an 80-mesh filter (manufactured by Wenzhou Haichuan Machinery Co., Ltd. ) The pass rate was 85.8%, the homogenate concentration (mass fraction) was required to be 22%, and 171.6kg of abalone roe homogenate was obtained for use.

[0051] 2. Aqueous ligand;

[0052] Select the sum of abalone egg protein polypeptide extraction ligands to be 429kg and distribute as follows;

[0053] 171.6kg of extracted ligands in Group A accounted for 40% of the total ligands;

[0054] Upper ligand: dextran (DX48) 10.3kg purified water (H 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com