Lengthened scraping film type rotary channel enhanced-extraction device and application thereof

An extraction equipment and micro-channel technology, which is applied in the field of extended scraping-film rotating micro-channel enhanced extraction equipment, can solve the problems that the organic phase cannot be clarified and extracted in time, the surface tension of the dispersion system is low, and the droplet size is small. Phase time, broaden the scope of application, increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the rotatable wiped-film microchannel reactor was used to extract and purify the chromium solution containing 200 ppm. Extraction agent and process parameters during extraction: the extraction agent is prepared from ethylhexyl phosphate mono-2-ethylhexyl (P507) and kerosene at a volume ratio of 3:7, and the volume ratio of chromium solution to extraction agent is 1: 1. The extraction temperature is 25°C, the rotation speed of the inner cylinder is 300r / min, and the extraction time is 15s, 30s, 45s, 60s, 90s, and 120s.

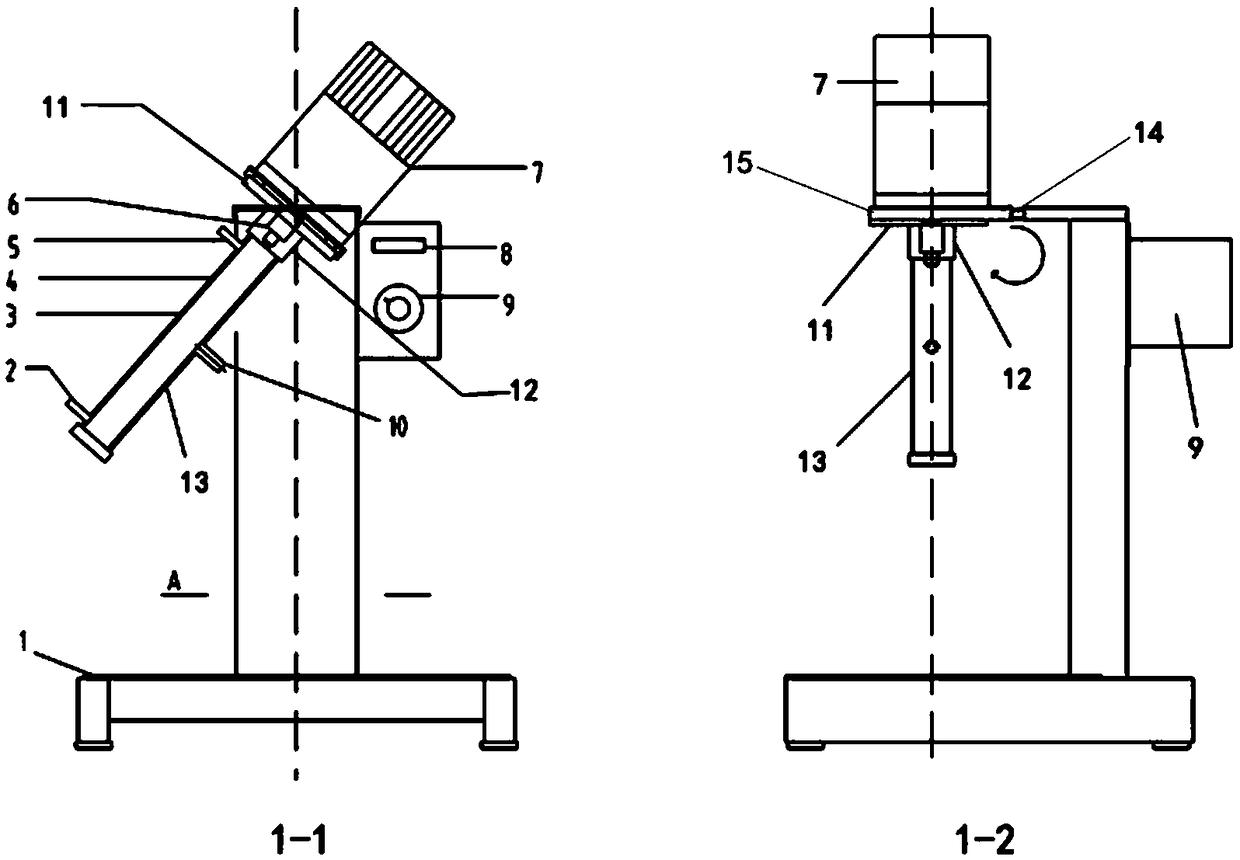

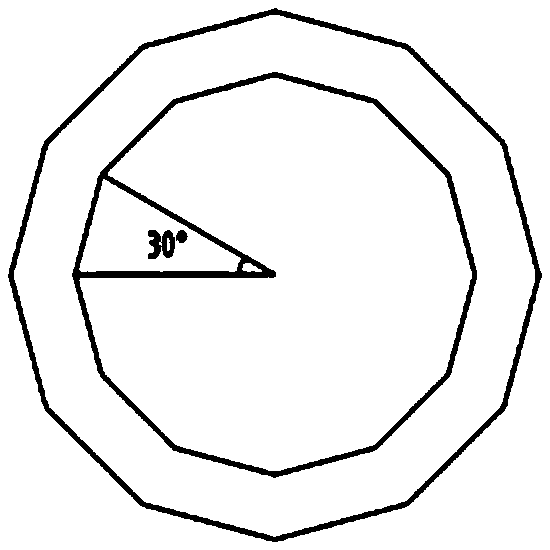

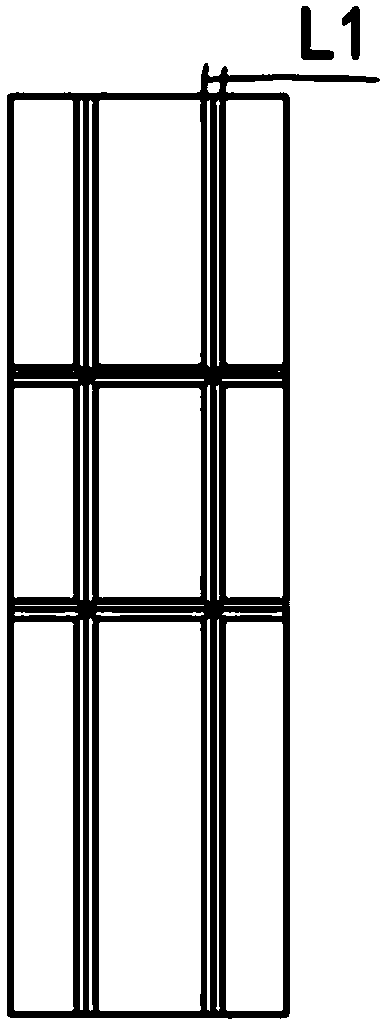

[0039] The extraction operation is as follows: Preheat the purified chromium solution and extractant to 25°C respectively, and then send the preheated purified chromium solution and extractant into the inner cylinder 3 through the upper feed port 5 and the lower feed port 2 respectively In the gap with the outer cylinder 4, when the gap is filled with liquid, the drive motor 7 is turned on at the same time to make the inner cylinder roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com