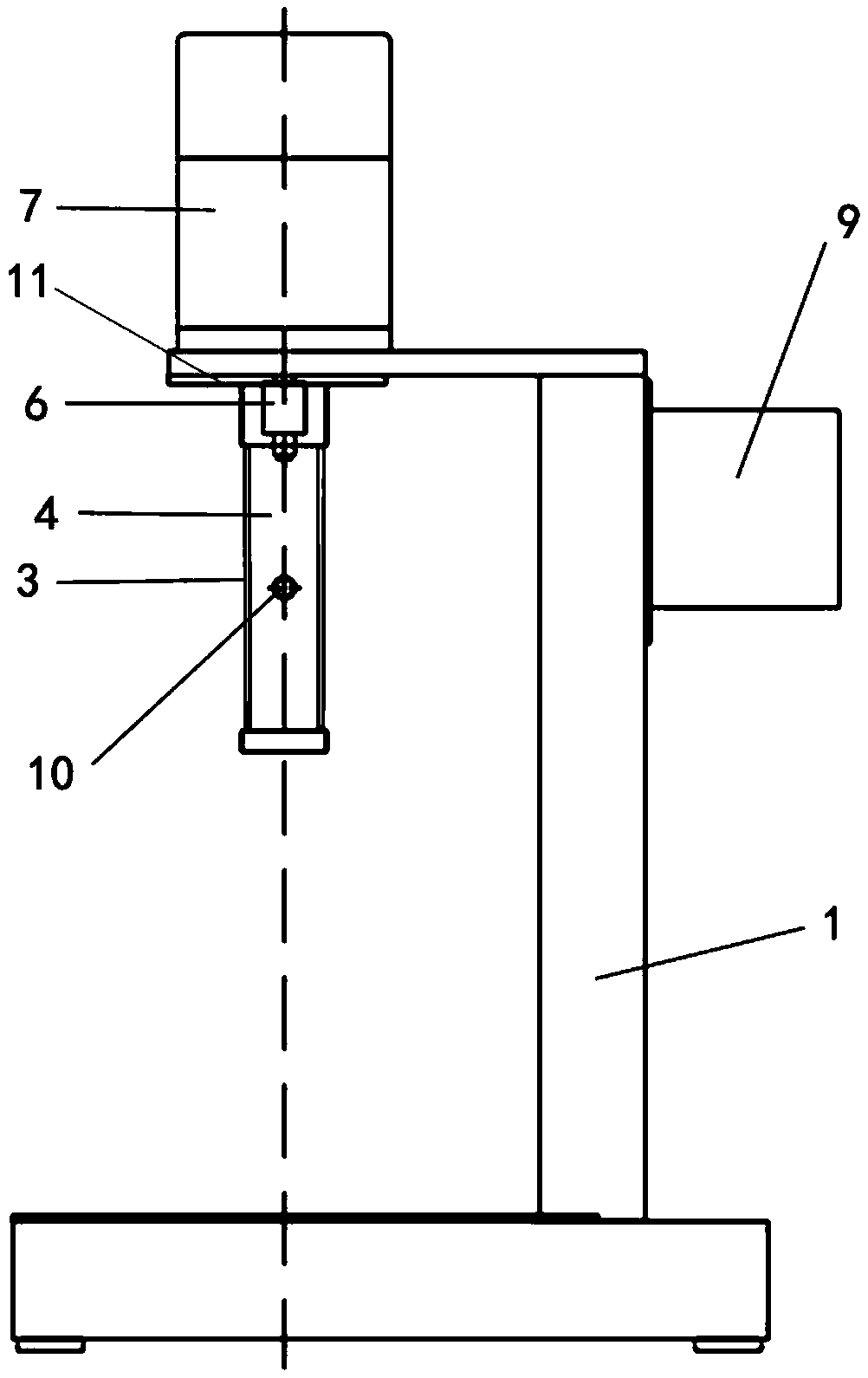

Film scratching type rotary micro-channel enhanced extraction equipment and application thereof

A technology of extraction equipment and micro-channels, which is applied in the field of wiped-film rotary micro-channel enhanced extraction equipment, can solve the problems of inability to obtain clarified extraction organic phase in time, low surface tension of dispersion system, small droplet size, etc., so as to shorten the phase separation. time, reduced equilibration time, reduced volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the above-mentioned scraped-film rotating microchannel enhanced extraction equipment is used to extract and purify the chromium solution containing 200 ppm of chromium. Extractant and process parameters during extraction: The extractant is prepared from ethylhexyl phosphate mono-2-ethylhexyl ester (P507) and kerosene in a volume ratio of 3:7, and the volume ratio of chromium solution to extractant is 1: 1. The extraction temperature is 25℃, the rotation speed of the inner cylinder is 500r / min, and the extraction time is 15s, 30s, 45s, 60s, 90s, 120s.

[0036] The extraction operation is as follows: preheat the purified chromium solution and extractant to 25°C respectively, and then send the preheated purified chromium solution and extractant through the syringe pump from the upper feed port 5 and the lower feed port 2 respectively In the gap between the inner cylinder 3 and the outer cylinder 4, when the liquid fills the gap, the drive motor 7 is turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com