Cathode materials for electricity storage device, electrode for electricity storage device and electricity storage device, and method for manufacturing them

The technology of a negative electrode material and manufacturing method, which is applied in the field of negative electrode materials for electric storage devices, can solve the problems of a large amount of lithium-containing reagents, excessive time, and damage to the material structure, and achieve the effect of improving the initial charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

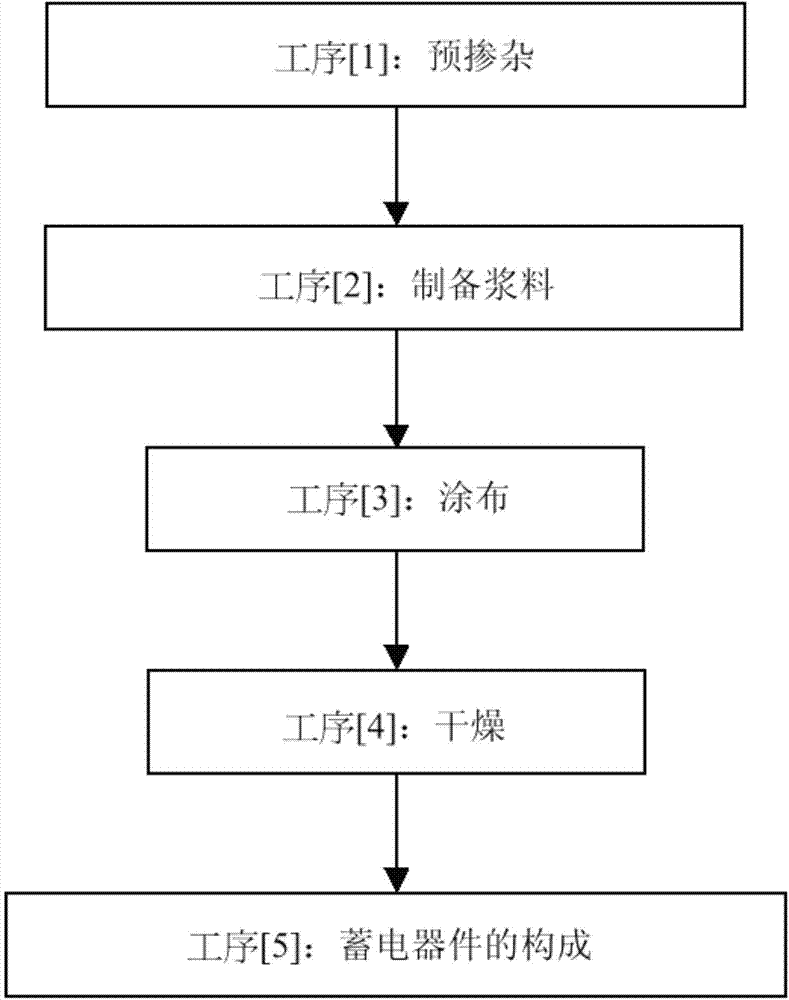

Method used

Image

Examples

Embodiment 1)

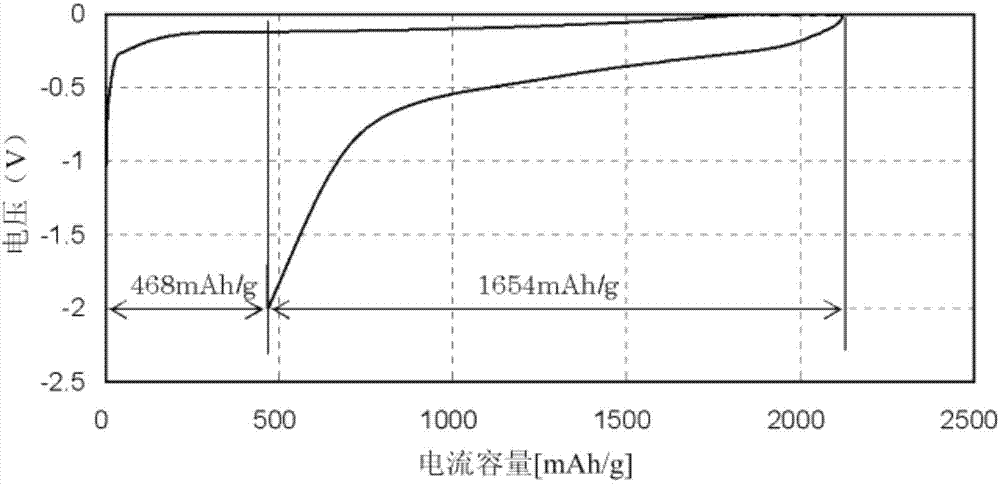

[0199] In an argon drying box with a moisture content of 1 ppm or less, prepare a Si-based material that can be doped with lithium (a silicon oxide represented by SiOx (x = 1.02) with an average particle diameter of 5 μm is coated with 5 wt% Carbon material) 0.75g, vapor-grown carbon fiber (VGCF manufactured by Showa Denko KK) 0.1g as a conductive material, and add ethylene carbonate and γ-butyrolactone (weight ratio: 20 : 80) 0.74g of mixed solvent, and mixed with a mortar.

[0200] A lithium metal foil with a thickness of 0.03 mm was cut into a square with a side length of 10 mm, and approximately 0.024 g of each was added to the obtained clay-like mixture, and kneaded and mixed while kneading. After the lithium metal has completely disappeared, the next lithium metal foil is added, and a total of 0.15 g of lithium metal is kneaded and mixed (equivalent to 760 mAh / g relative to the weight of the Si-based material that can be doped with lithium). After kneading and mixing, the ...

Embodiment 2~5)

[0213] In the same process as in Example 1, a mixture of ethylene carbonate and γ-butyrolactone (weight ratio: 20:80) was added to the Si-based material that can be doped with lithium and the vapor-grown carbon fiber (VGCF manufactured by Showa Denko Corporation) Solvent, use a mortar for mixing.

[0214] A lithium metal foil of 0.03 mm was cut into a square with a side length of 10 mm, approximately 0.024 g was added to the obtained clay-like mixture, and kneaded and mixed while kneading.

[0215] This mixture was heat-treated for 5 hours at various temperatures (Example 2: 200°C, Example 3: 400°C, Example 4: 600°C, and Example 5: 1300°C).

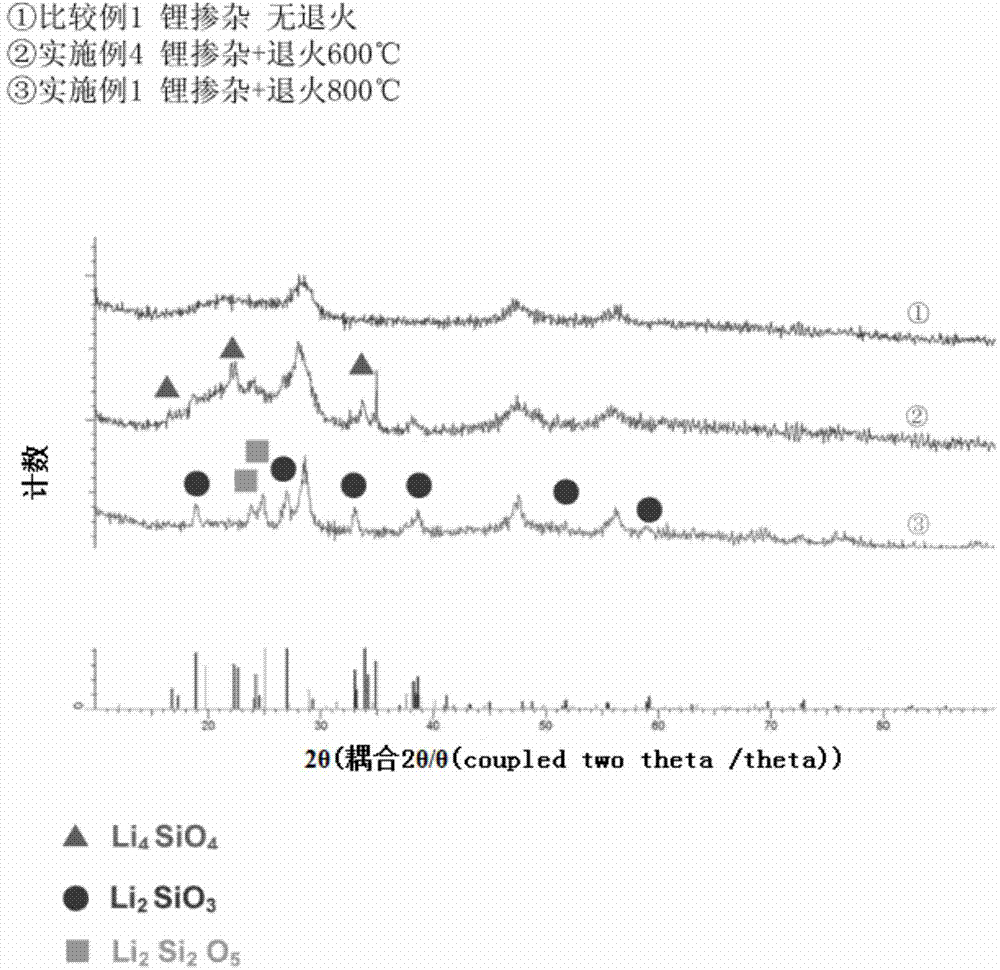

[0216] After confirming the X-ray diffraction pattern of the heat-treated powder obtained in this way, observe the broad peaks around 2θ=28.4°, 47.3°, and 56.1° attributable to the Si-based material that can be doped with lithium, and observe that it is attributed to Li 2 SiO 3 , Li 2 Si 2 O 5 , Li 4 SiO 4 Peak. Will belong to Li 2 SiO 3 18.9° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com