Bidirectional TVS and manufacturing method of bidirectional TVS

A technology of diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unfavorable device size reduction, large leakage of bidirectional TVS diodes, etc., and achieve small leakage, high reliability, and overall chip The effect of area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

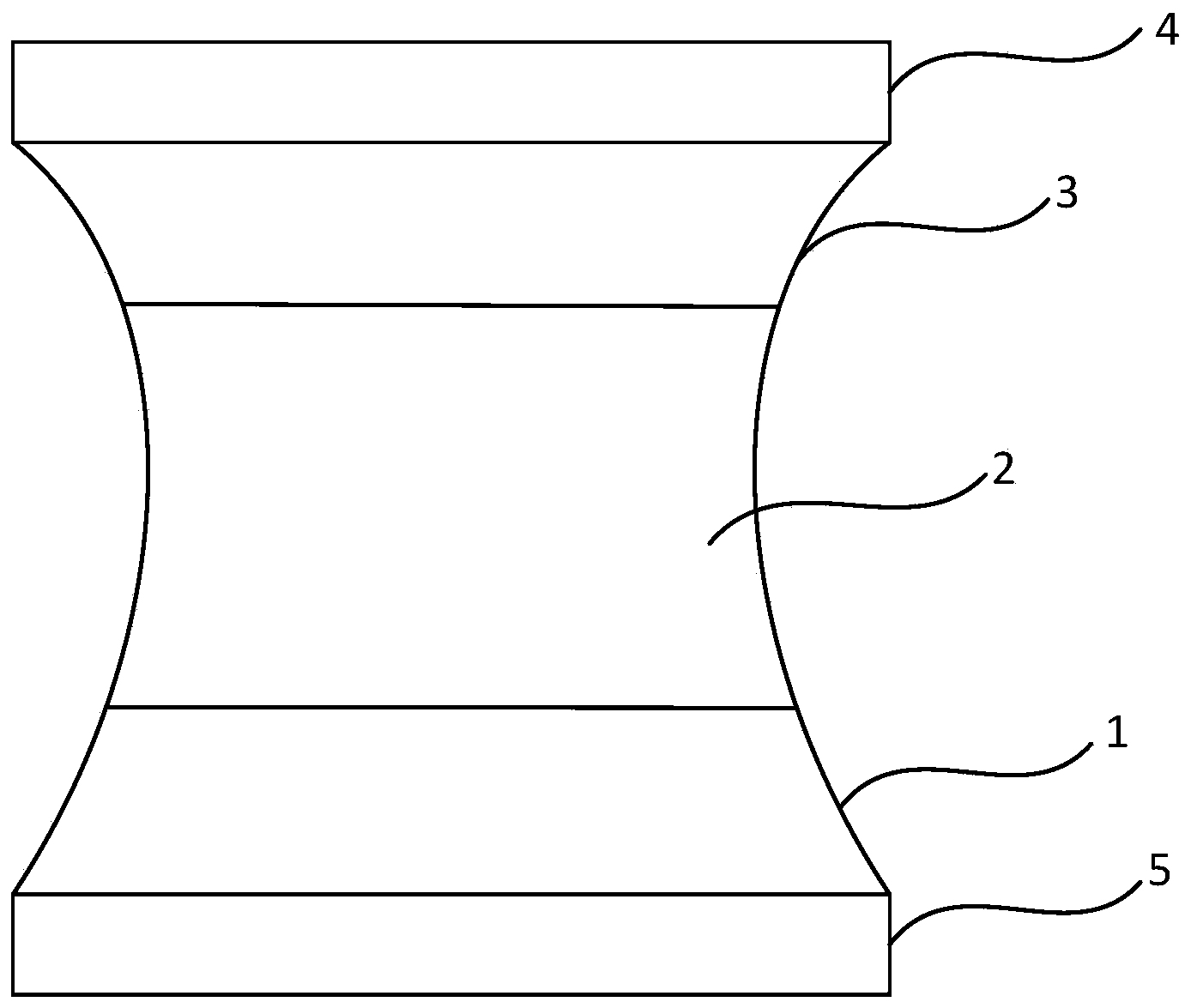

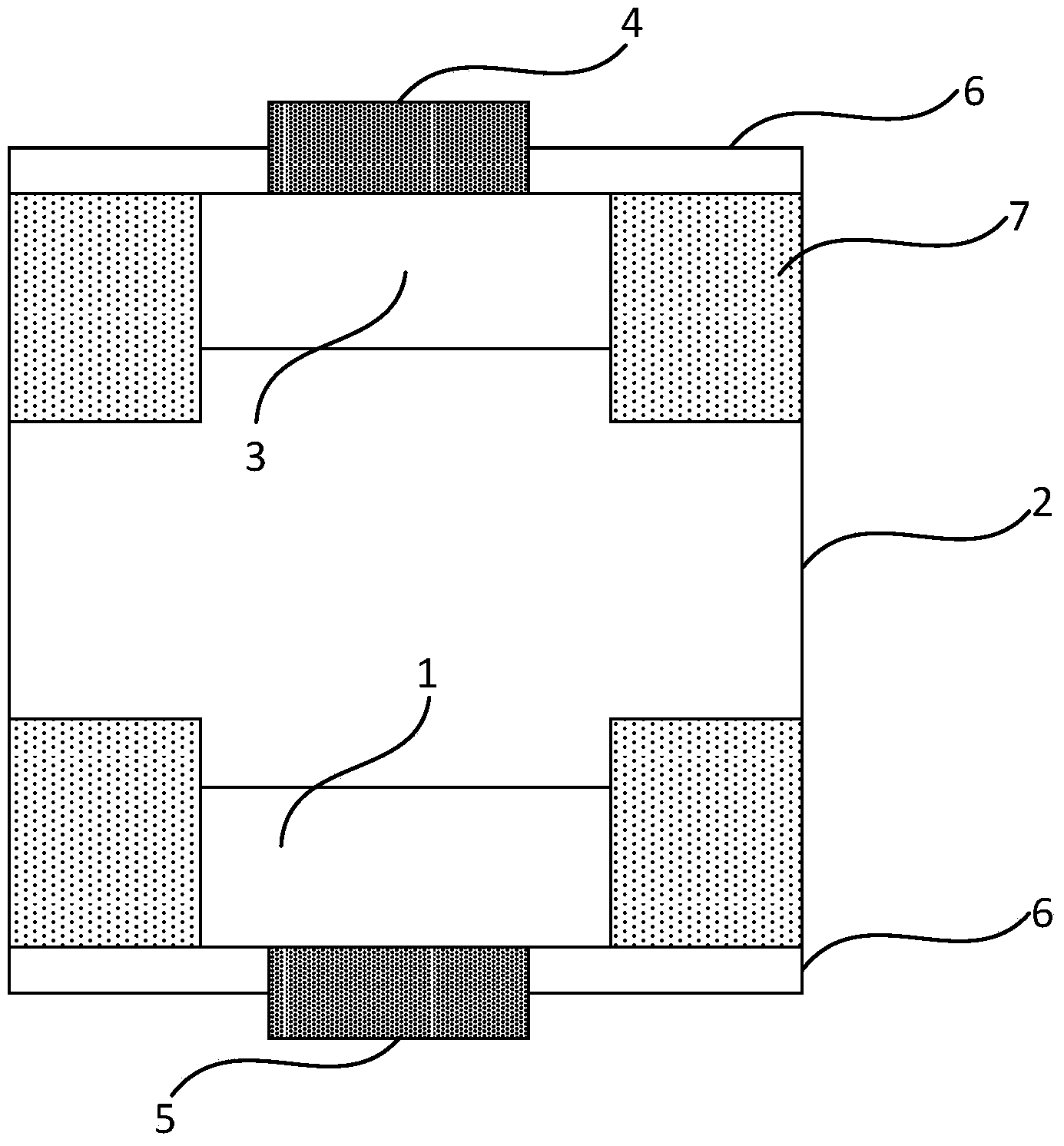

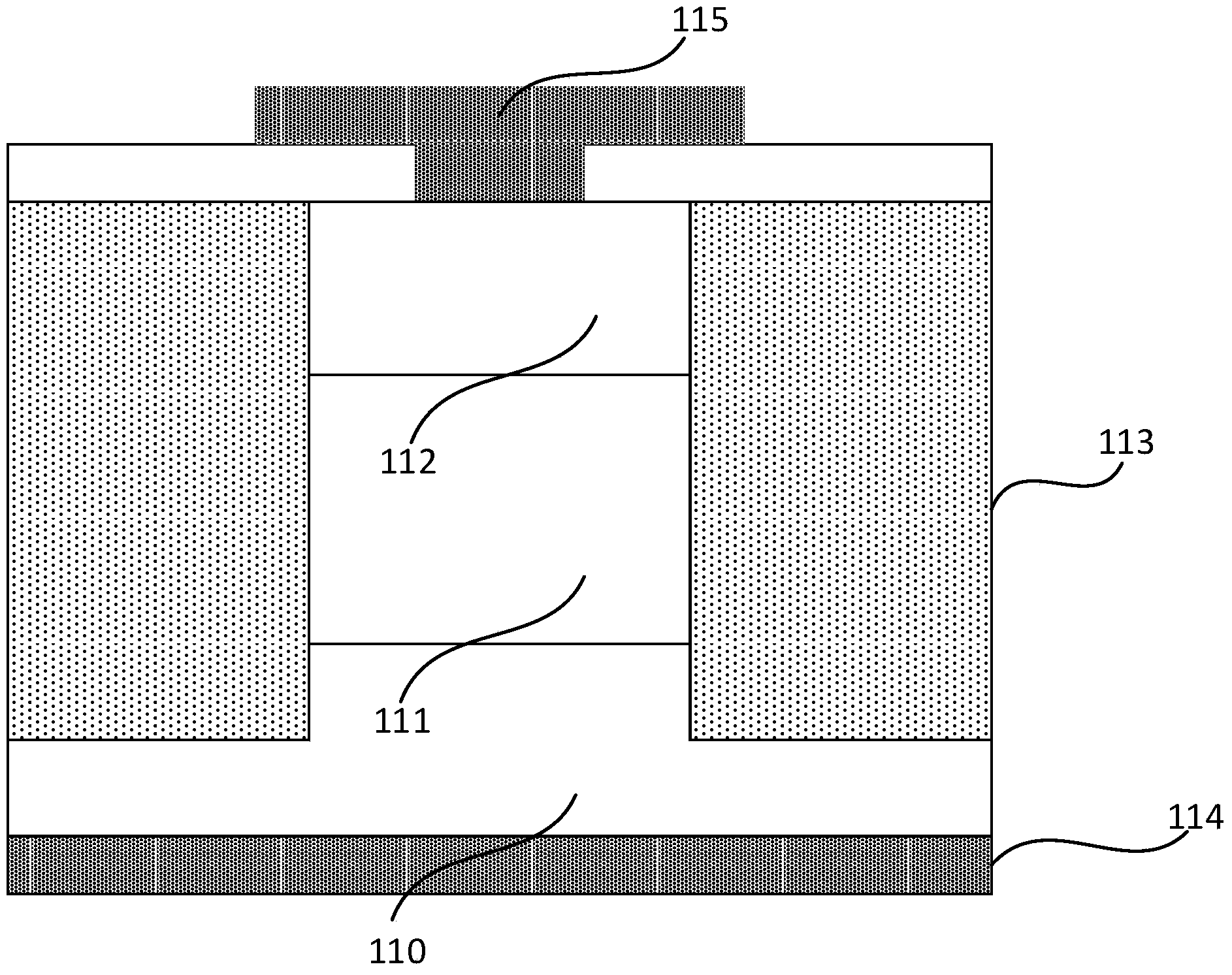

[0057] refer to Figure 3-6 , the manufacture method of bidirectional TVS diode of the present invention, comprises the following steps:

[0058] forming a second conductivity type epitaxial layer 101 on a first conductivity type substrate 100;

[0059] Photolithography and dry etching processes form a plurality of trenches 103 in the second conductivity type epitaxial layer 101, and each trench 103 passes through the second conductivity type epitaxial layer 101 and extends to the first conductivity type substrate middle bottom 100;

[0060] filling each trench 103 with an oxide layer by chemical vapor deposition;

[0061] Doping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com