Heat exchanger special for production of neodymium iron boron magnetic powder

A heat exchanger, neodymium-iron-boron technology, applied in the field of special heat exchangers produced by neodymium-iron-boron magnetic powder, can solve the problems of easy-to-freeze transportation pipelines, waste of water resources and energy, and high production costs, so as to save water resources, The effect of reducing waste of resources and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

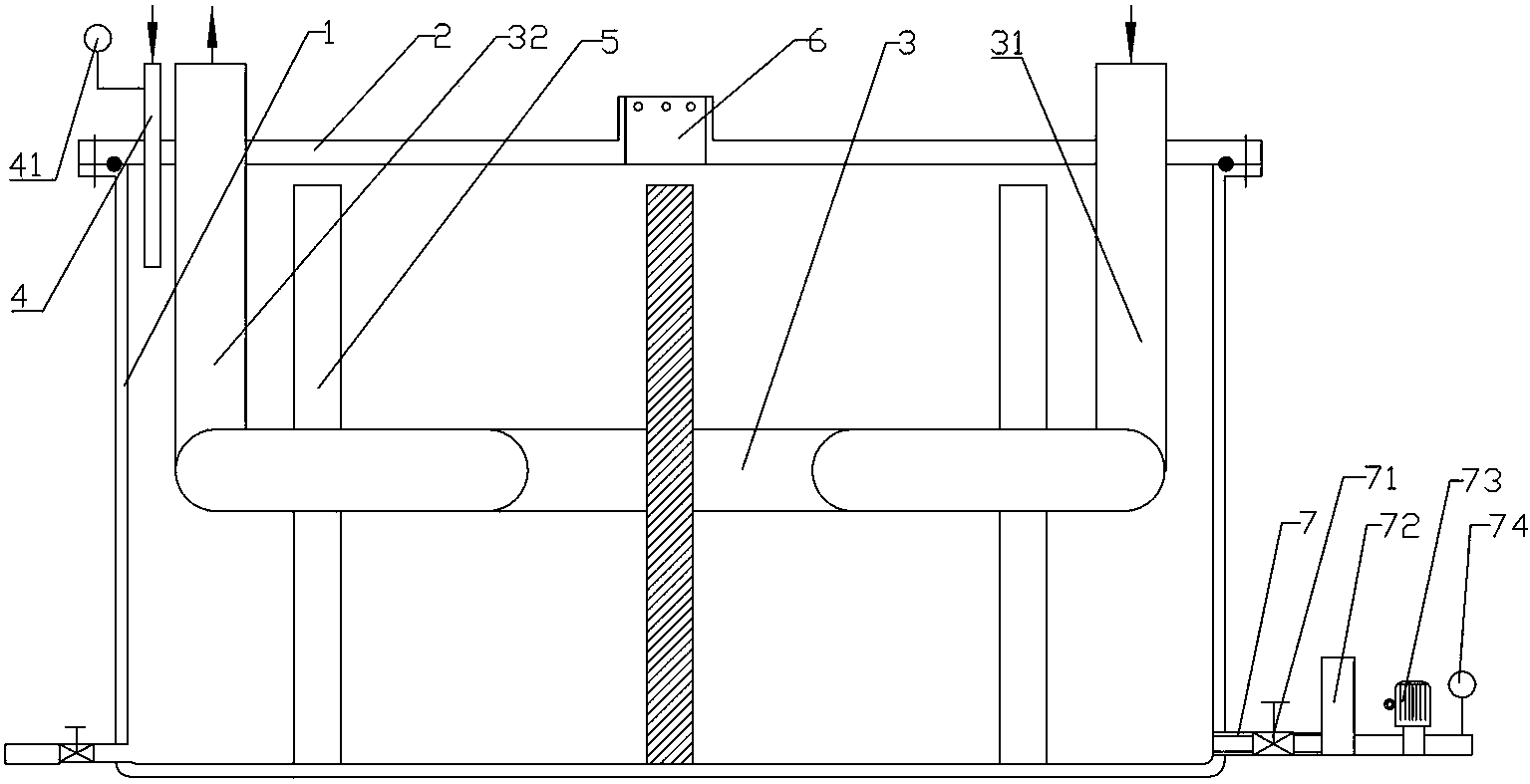

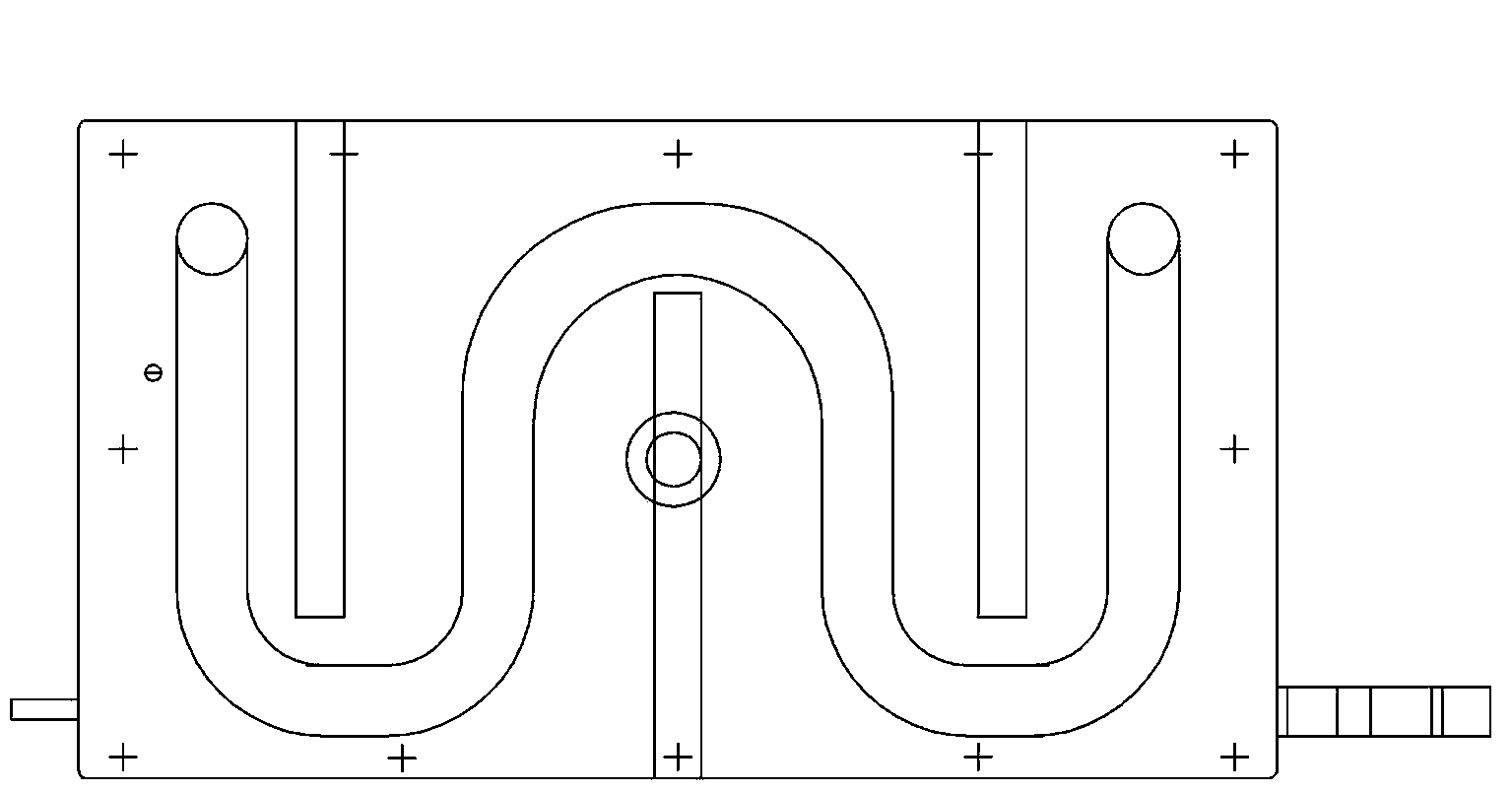

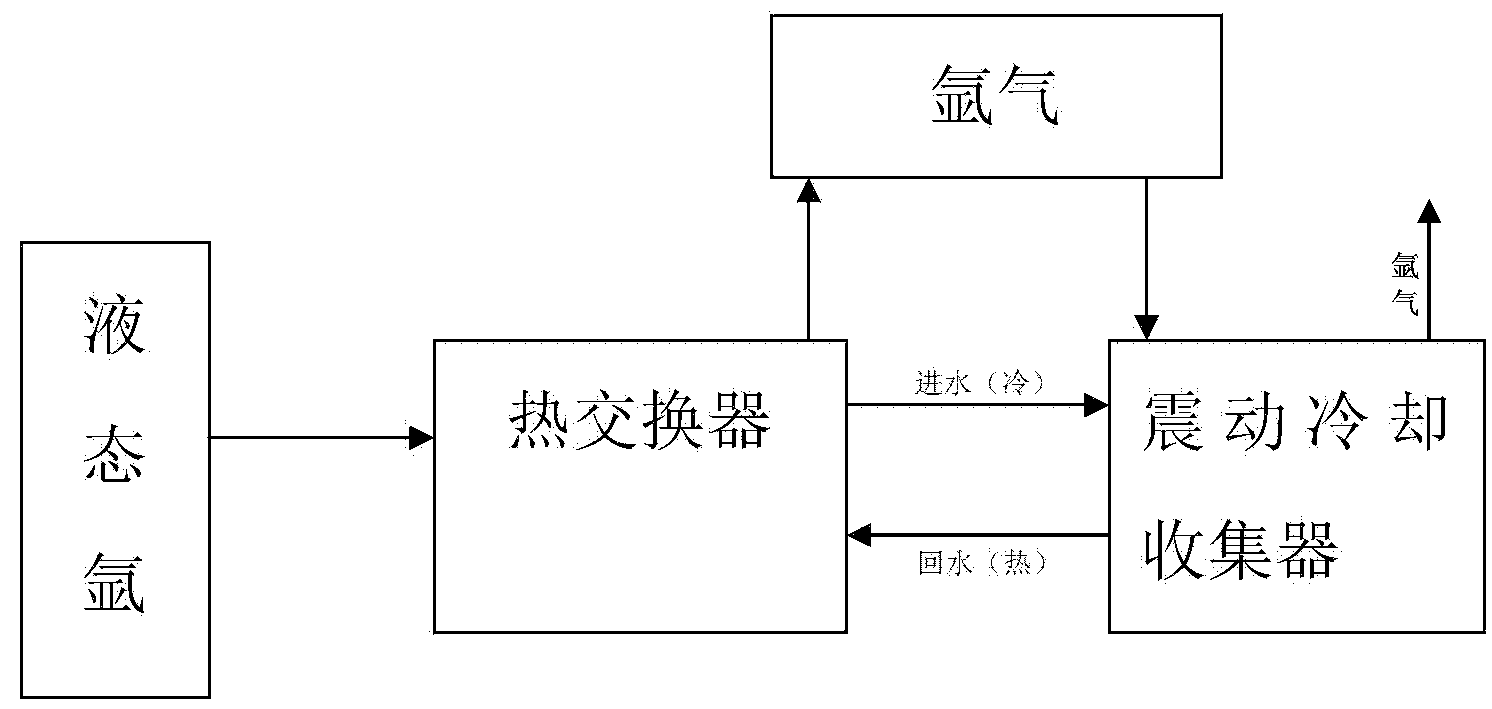

[0016] Embodiment 1, the present invention comprises box body 1, partition plate 5, cover plate 2, vent valve 6, is characterized in that: three or more partition boards 5 are arranged in box body 1, can make return water flow zigzag, increase The contact time and contact area between the return water and the refrigeration pipe 3 make the return water cool down faster. The cabinet 1 is provided with an outlet pipe 7, and the cooled water enters the cooling water circulation system produced by NdFeB magnetic powder through the outlet pipe. The refrigeration pipe 3 It is installed in the tank 1 and is fully in contact with the return water in the tank 1. The cooling pipe 3 is filled with liquid inert gas to cool the return water and absorb the heat energy required for gasification. After gasification, it can be injected with neodymium iron The multi-stage quenching device produced by boron magnetic powder, the top of the box body 1 is provided with a cover plate 2, and the cover ...

Embodiment 2

[0017] Embodiment 2, the ventilation valve 6 of the present invention is arranged at the center of the cover plate 2 and communicates with the inside of the box body 1, and can communicate the temperature difference between the inside and outside of the box to balance the air temperature. refer to Figure 1 to Figure 3 , all the other are with embodiment 1.

Embodiment 3

[0018] Embodiment 3, the input pipe 31 and the output pipe 32 of the refrigeration pipe 3 of the present invention are arranged on the cover plate 2 close to the inner walls of both sides of the box body 1, and the outer wall of the refrigeration pipe 3 is also provided with heat transfer fins, which can speed up the heat transfer speed. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com