A kind of die-casting forged aluminum alloy and production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

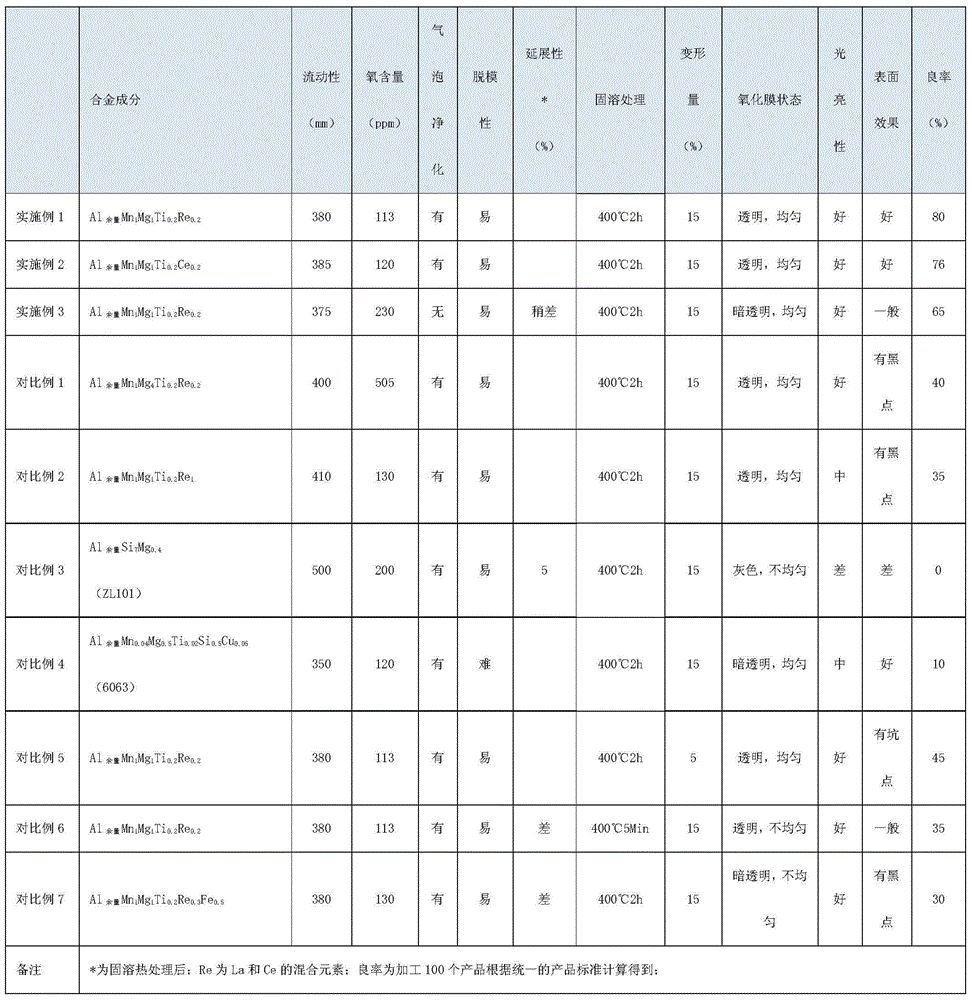

Image

Examples

Embodiment 1

[0066] Mix industrial pure aluminum, aluminum-manganese alloy with 10% by weight of manganese, industrial pure magnesium, aluminum-titanium alloy with 5% by weight of titanium, and aluminum-rare-earth alloy with 10% by weight of rare earth, put it into an induction melting furnace, adjust Components get Al 余量 mn 1 Mg 1 Ti 0.2 Re 0.2 The alloy melt, in which the silicon content and iron content are controlled within 0.01%2 The gas is subjected to bubble floating purification treatment, and the melt temperature is controlled at 760°C.

[0067] The alloy melt is casted with a 160T cold die-casting machine, and the release machine uses a silicon-free water-based release agent to obtain a blank product, which is then polished, and then forged and trimmed. The forging temperature is room temperature, and then the blank The product is subjected to solid solution heat treatment. The heat treatment system is as follows: the temperature is 400°C, the time is 2 hours, and then the oi...

Embodiment 2

[0070] Mix industrial pure aluminum, aluminum-manganese alloy with 10% by weight of manganese, industrial pure magnesium, aluminum-titanium alloy with 5% by weight of titanium, and aluminum-rare-earth alloy with 10% by weight of rare earth, and put them into an induction melting furnace to adjust the composition Get Al 余量 mn 1 Mg 1 Ti 0.2 Re 0.2The alloy melt, in which the silicon content and iron content are controlled within 0.01%2 The gas is subjected to bubble floating purification treatment, and the melt temperature is controlled at 760°C.

[0071] The alloy melt is casted with a 160T cold die-casting machine, and the release machine uses a silicon-free water-based release agent to obtain a blank product, which is then polished, and then forged and trimmed. The forging temperature is room temperature, and then the blank The product is subjected to solid solution heat treatment. The heat treatment system is as follows: the temperature is 400°C, the time is 2 hours, and...

Embodiment 3

[0074] Mix industrial pure aluminum, aluminum-manganese alloy with 10% by weight of manganese, industrial pure magnesium, aluminum-titanium alloy with 5% by weight of titanium, and aluminum-rare-earth alloy with 10% by weight of rare earth, and put them into an induction melting furnace to adjust the composition Get Al 余量 mn 1 Mg 1 Ti 0.2 Re 0.2 In the alloy melt, the silicon content and iron content are controlled within 0.01%<Si<0.2%, 0.01%<Fe<0.4%, respectively, and the melt temperature is controlled at 760°C.

[0075] The alloy melt is casted with a 160T cold die-casting machine, and the release machine uses a silicon-free water-based release agent to obtain a blank product, which is then polished, and then forged and trimmed. The forging temperature is room temperature, and then the blank The product is subjected to solid solution heat treatment. The heat treatment system is as follows: the temperature is 400°C, the time is 2 hours, and then the oil quenching treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com