A kind of preparation method of proton conductor based on grafted titanium dioxide nanotube polyelectrolyte brush

A technology of polyelectrolyte brushes and titanium dioxide, applied in circuits, fuel cells, electrical components, etc., can solve the problems of low proton conductivity, high manufacturing cost, and limited applications, and achieve good proton conductivity and good water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Concrete preparation process is as follows:

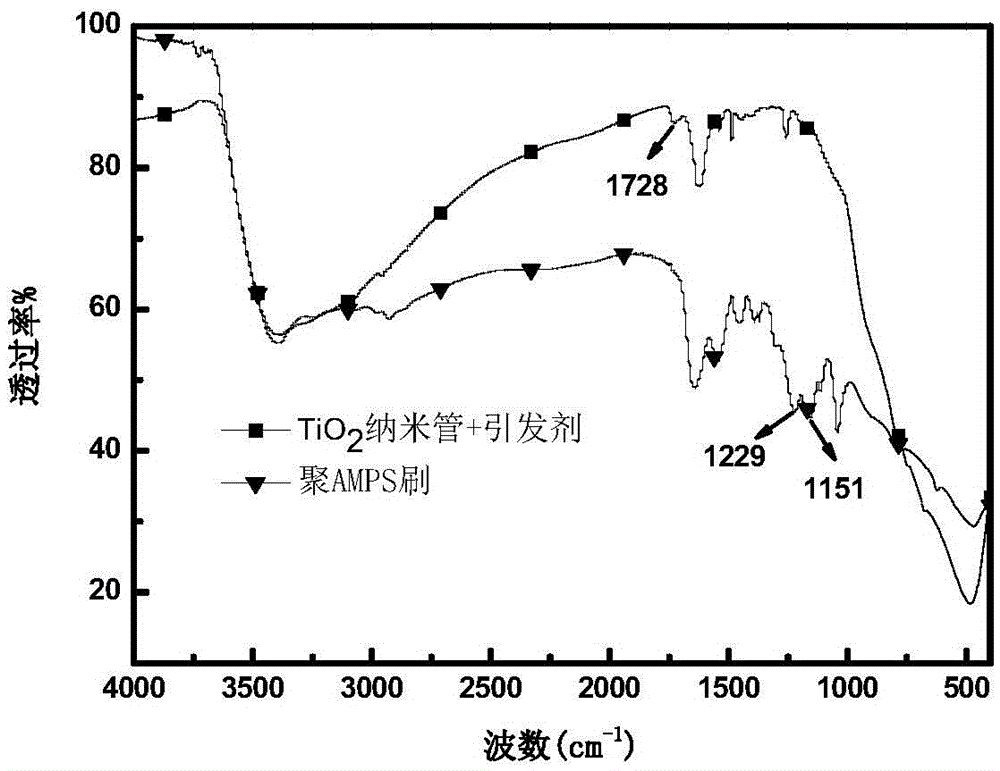

[0024] Step 1: Add TiO 2 Nanotube, join in the there-necked flask, add triethylamine in the there-necked flask, then measure the azo initiator solution, transfer the initiator solution to the constant burette, N 2 For protection, the initiator solution in the constant burette was slowly dropped into the there-necked flask, stirred at room temperature for 24 hours, and the reacted product was transferred to the centrifuge tube, washed alternately with toluene and methanol solution, each solvent was washed three times, Finally, transfer the lower sediment in the centrifuge tube to a watch glass and dry at 30°C. The product after drying is an azo initiator anchored on TiO 2 Product after nanotube surface.

[0025] Step 2: Weigh TiO 2 The nanotube-initiator product is added to the two-necked bottle, and then the carbon-carbon double bond-containing electrolyte monomer solution is added to the two-necked bottle, and the air i...

Embodiment 1

[0028] Weigh 1.28g of TiO 2 Nanotubes, join in the there-necked flask of 250ml, add the triethylamine of 1ml in the there-necked flask, then measure the azo initiator solution of 50ml, 13mmol / L, transfer the initiator solution in the constant burette, N 2 For protection, the initiator solution in the constant burette was slowly dropped into the there-necked flask, stirred at room temperature for 24 hours, and the reacted product was transferred to the centrifuge tube, washed alternately with toluene and methanol solution, each solvent was washed three times, Finally, transfer the lower sediment in the centrifuge tube to a watch glass and dry at 30°C. The product after drying is an azo initiator anchored on TiO 2 Product after nanotube surface.

[0029] Weigh 1gTiO 2 Nanotube-initiator product, join in the two-neck bottle of 100ml, then measure 10mL of 2-methyl-2-[(1-oxo-2-propenyl)amino]-1-propanesulfonic acid sodium salt mono The body solution (50% aqueous solution) was a...

Embodiment 2

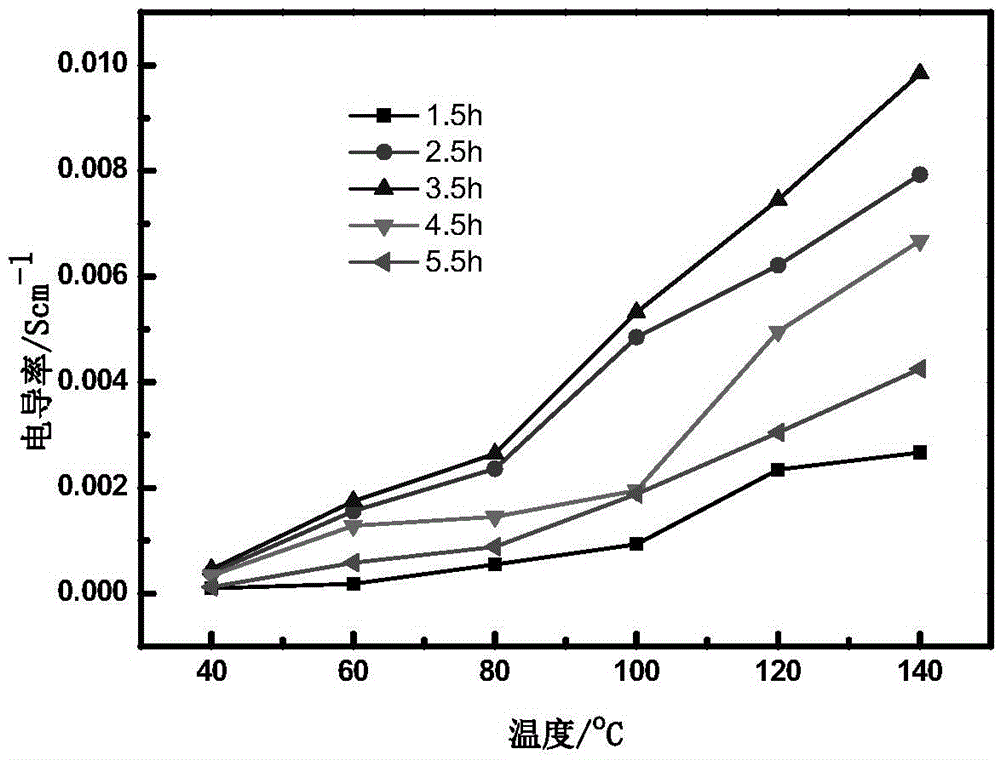

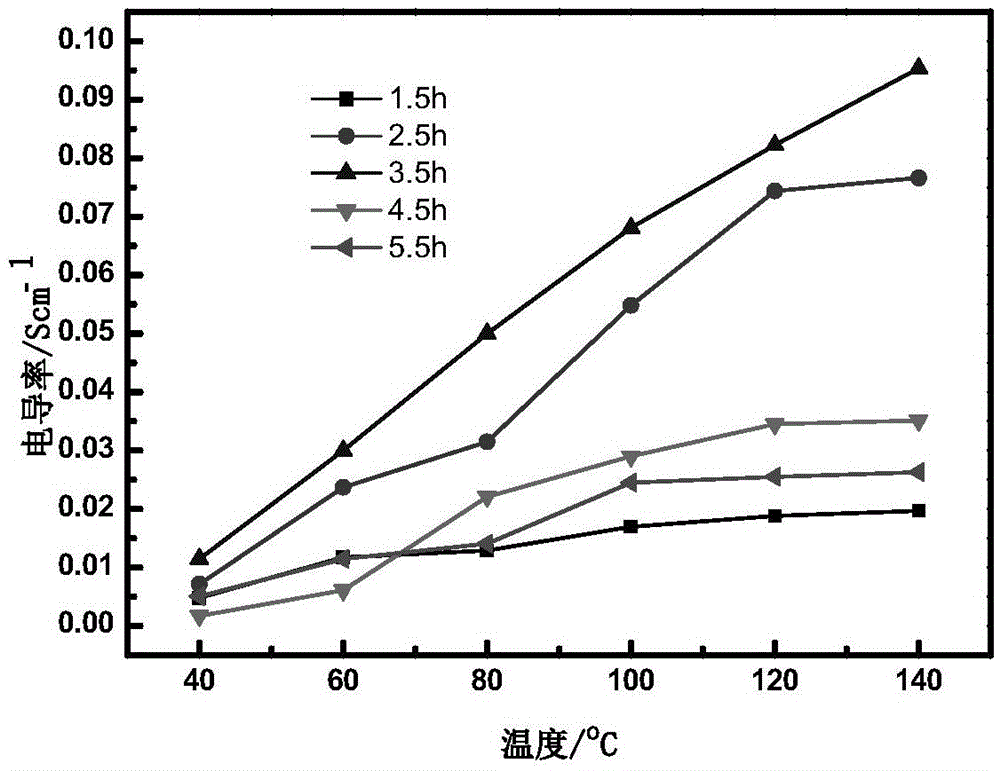

[0034]This embodiment is roughly the same as Example 1, except that the concentration of different azo initiators is selected, which are respectively 0.5mmol / L, 2.8mmol / L, 5.5mmol / L, 11mmol / L, 13mmol / L, 5 groups of parallel products were obtained, the purpose is to investigate the effect of different initiator concentrations on the polymer grafting density.

[0035] Elemental analysis and testing were carried out on the 5 groups of products, and the obtained nitrogen content and monomer grafting density are shown in Table 1: It can be seen from Table 1 that with the continuous increase of the initiator concentration, the N element content and grafting density are both at the same time. However, when the initiator concentration reaches 13mmol / L, the content of N element basically no longer increases and reaches saturation. The relationship between the initiator concentration and the content of N element fully conforms to the first-order process reaction kinetics process. Using t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com