Solvent-free epoxy internal anti-drag coating for natural gas pipeline

A natural gas pipeline, solvent-free technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problem of low density of paint film, achieve the effect of excellent performance, lower requirements, convenient production and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

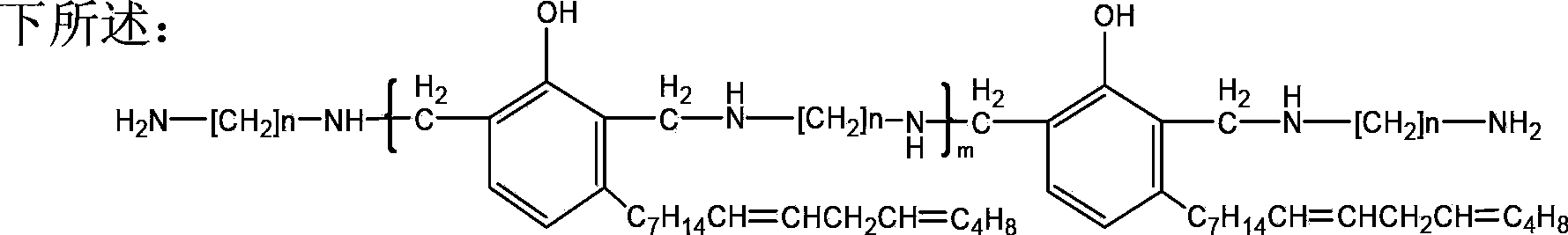

Method used

Image

Examples

Embodiment 1

[0026] This example consists of components A and B. The ratio of component A is: in 100% by weight, the film-forming resin with an average equivalent weight of 210 accounts for 45%, the dispersant accounts for 0.3%, the active diluent accounts for 21.9%, the anti-settling agent accounts for 0.5%, and the leveling agent accounts for 45%. 0.4%, coupling agent 0.6%, defoamer 0.3%, pigment 11%, wollastonite powder 9%, silica powder 6%, barium sulfate 5%.

[0027] The curing agent of component B accounts for 24% of the total weight of component A.

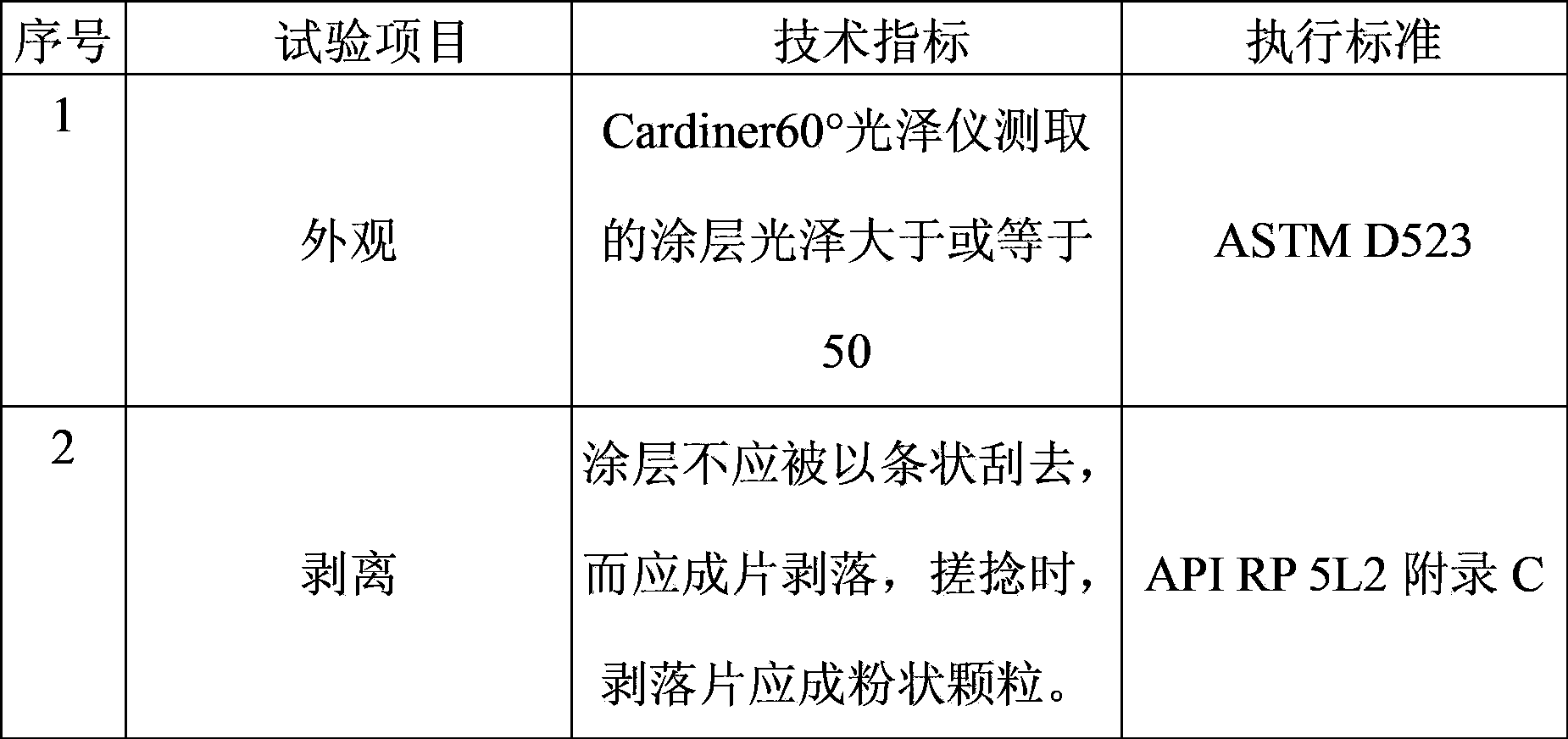

[0028] The performance test results of the materials are shown in Table 2:

[0029] Table 2 Performance test results of solvent-free epoxy internal drag-reducing coatings

[0030]

[0031]

Embodiment 2

[0033] This example consists of components A and B. The ratio of component A is 100% by weight, the film-forming resin with an average equivalent weight of 180 accounts for 53%, the dispersant accounts for 0.3%, the active diluent accounts for 15.8%, the anti-settling agent accounts for 0.2%, and the leveling agent accounts for 0.5%, coupling agent 0.7%, defoamer 0.5%, pigment 10%, wollastonite powder 9%, silica powder 5%, barium sulfate 5%;

[0034] The curing agent of component B (651 curing agent) accounts for 30% of the total weight of component A.

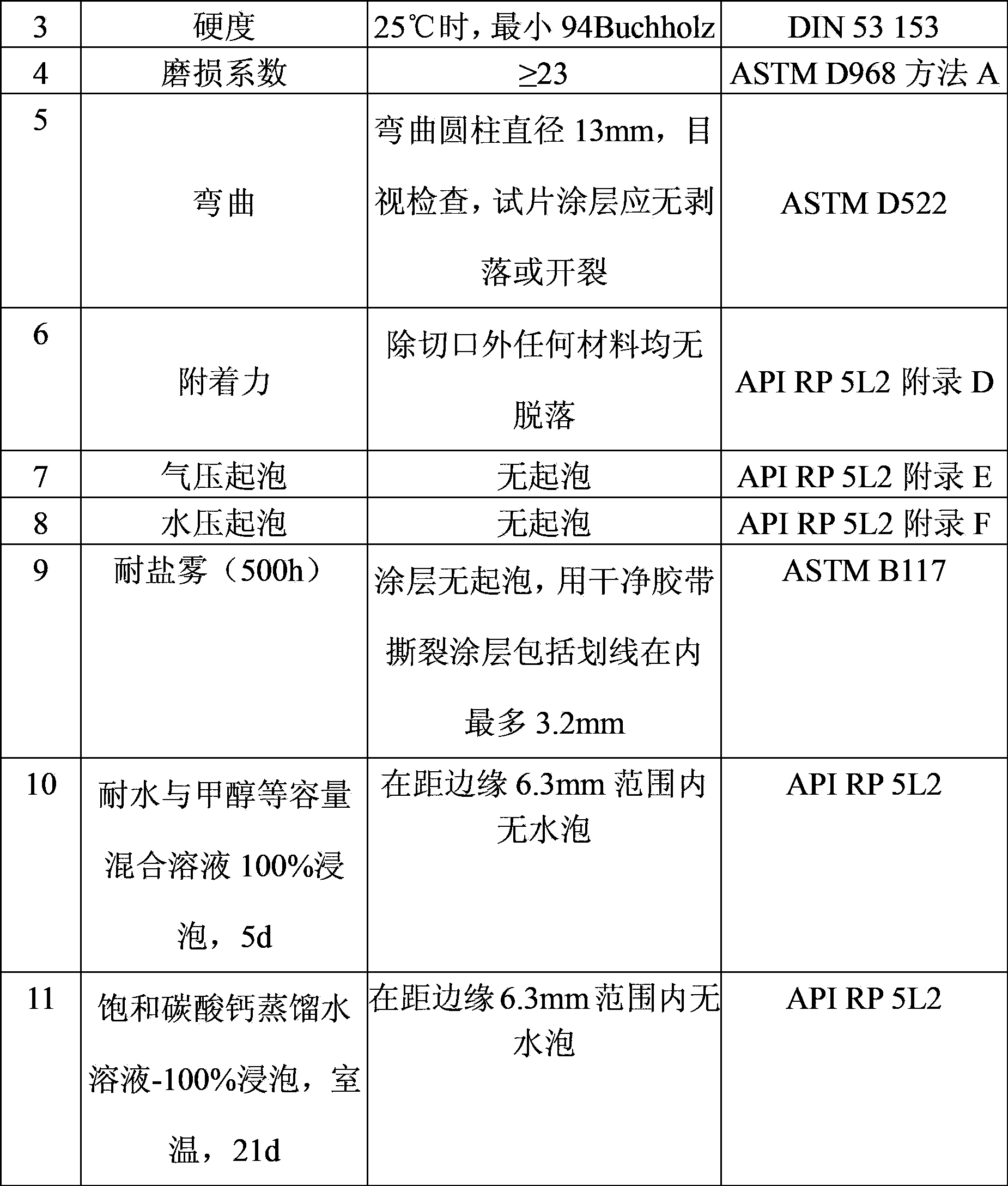

[0035] The performance test results of the materials are shown in Table 3:

[0036] Table 3 Performance test results of solvent-free epoxy internal drag-reducing coatings

[0037]

[0038]

[0039] After many tests in this example, the coating is safe and environmentally friendly in construction, has strong adhesion to steel, and has good chemical resistance, which can ensure the quality of drag reduction in long-dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com