Surface modification method of plant fiber

A plant fiber and surface modification technology, applied in plant fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of unrecognized compatibility and other problems, and achieve the effects of low production cost, high production efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

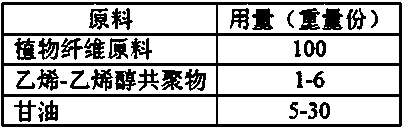

Method used

Image

Examples

Embodiment 1

[0016] 1 g of ethylene-vinyl alcohol copolymer with an ethylene molar content of 70% was crushed into a 20-mesh powder, dried in a vacuum oven at 90 °C for 8 h, and then mixed with 5 g of glycerol evenly. 100 grams of wood powder was removed from impurities, crushed, sieved, dried in vacuum at 80°C for 2 hours, and then put into a high-mixer at 150°C, and the mixture of ethylene-vinyl alcohol copolymer and glycerin was added dropwise, and mixed with 3000 Mix at r / min for 10 min, take out the mixture to obtain modified wood powder.

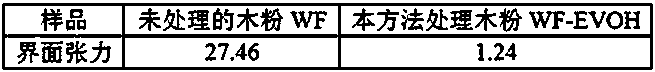

[0017] The interfacial tension (mJ / m) of wood powder and polypropylene treated by this method 2 )as follows:

[0018]

[0019] The above results show that this method can effectively reduce the polarity of wood flour and improve the compatibility with polypropylene. Add 40 parts of wood flour modified by this method to 100 parts of polypropylene for the production of wood-plastic composite boards, and use a universal material testing machine ...

Embodiment 2

[0021] 6 g of ethylene-vinyl alcohol copolymer with an ethylene molar content of 30% was crushed into a 100-mesh powder, dried in a vacuum oven at 92 °C for 8 h, and then mixed with 30 g of glycerin. 100 grams of bamboo powder was removed from impurities, crushed, sieved, and then vacuum-dried for 2 hours at a temperature of 80°C, then put into a high-mixer at 190°C, and the mixture of ethylene-vinyl alcohol copolymer and glycerin was added dropwise, and mixed with 6000 r / min mixed for 5 min to obtain modified bamboo powder.

[0022] Add 40 parts of bamboo powder modified by this method into 100 parts of high-density polyethylene for the production of wood-plastic composite boards, use a universal material testing machine to test the mechanical properties of the gained composite material, the tensile strength is 38.26 MPa, the impact strength 14.02 kJ / m 2 , the bending strength is 47.84 MPa.

Embodiment 3

[0024] 3 g of ethylene-vinyl alcohol copolymer with an ethylene molar content of 44% was crushed into a 60-mesh powder, dried in a vacuum oven at 91 °C for 8 h, and then mixed with 15 g of glycerin. 100 grams of jute stalks were removed from impurities, crushed, sieved, vacuum-dried for 2 hours at a temperature of 80°C, and then put into a high-speed mixer at 175°C. Mix at r / min for 7 min to obtain modified jute stalks.

[0025] Add 40 parts of jute stalks modified by this method to 100 parts of polyvinyl chloride for the production of wood-plastic composite boards, and use a universal material testing machine to test the mechanical properties of the composite materials. The tensile strength is 34.36 MPa, and the impact strength is 15.02 kJ / m 2 , the bending strength is 43.65 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com