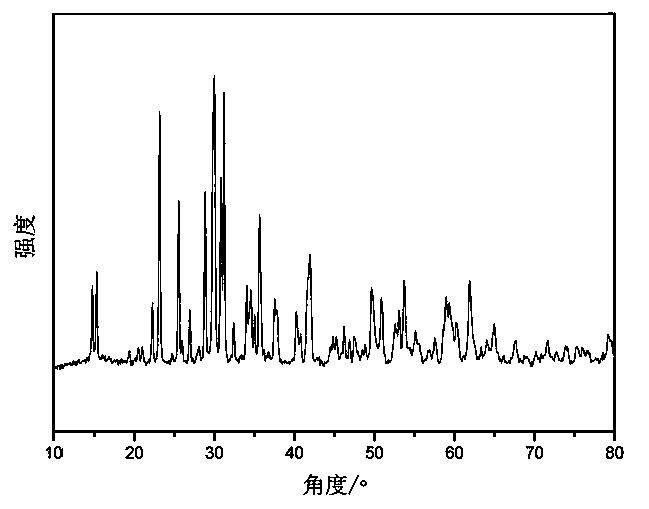

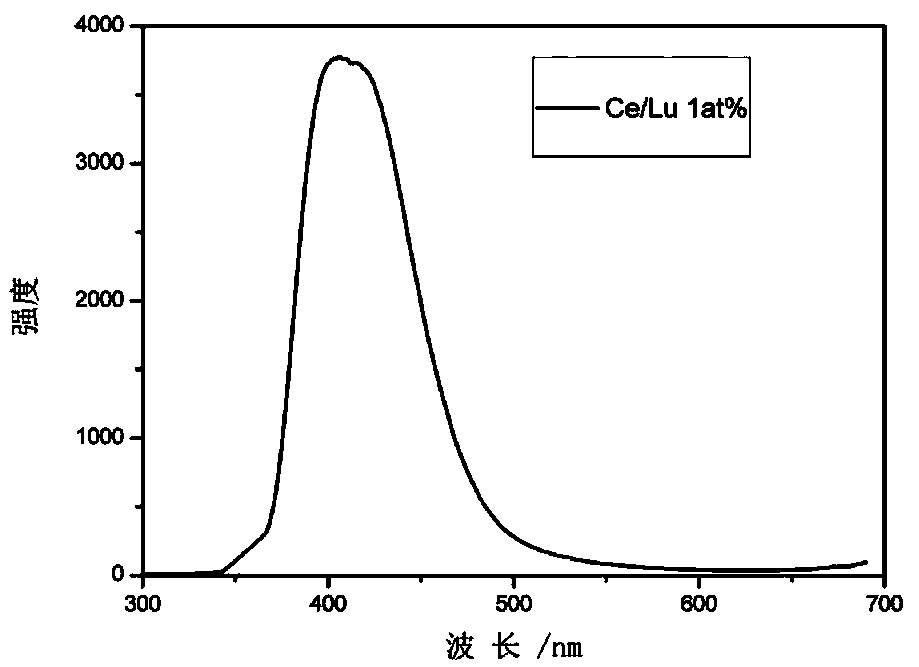

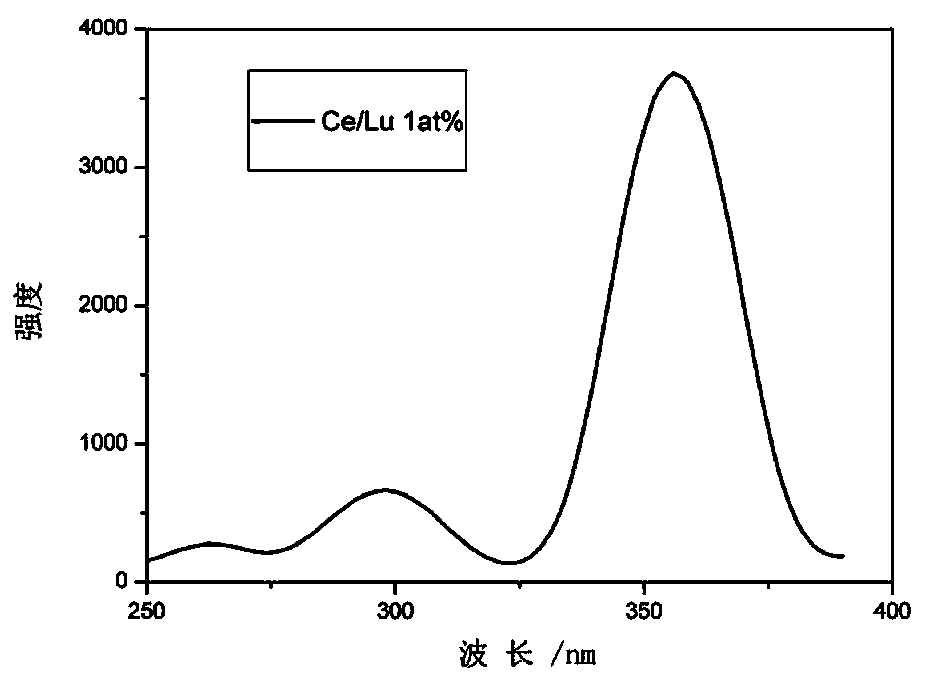

Cerium doped silicate lutetium scintillating fiber and electrostatic spinning synthetic method thereof

A scintillation fiber and electrospinning technology, applied in fiber processing, filament/thread forming, spinning solution preparation, etc., to achieve excellent scintillation performance, continuous shape, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 4.64g of lutetium oxide, add 15g of concentrated nitric acid, heat and stir until dissolved, then evaporate the solution to obtain white solid lutetium nitrate; (2) add 15g of ethanol, stir and dissolve the solid lutetium nitrate, and then add 0.0506g of cerium nitrate, then add 1g of polyvinyl butyral, stir until transparent viscous liquid; (3) Weigh 2.5g of tetraethyl orthosilicate, add to the mixture of 2.5g of absolute ethanol and 0.5g of water Add 0.05g of concentrated hydrochloric acid, stir for 1 hour, and mix evenly; (4) Mix the solution prepared in step (2) with the solution prepared in step (3), and stir for 1 hour to obtain the spinning stock solution; (5) The prepared spinning stock solution is added to the syringe, the spinning voltage is adjusted to 15kV, the injection speed parameter is 1ml / h, the needle is selected as a No. 7 needle, the receiving device is a drum, the drum speed is 10m / min, and the length of the cylinder is 300mm. The diameter...

Embodiment 2

[0041] (1) Weigh 9.28g of lutetium oxide, add 30g of concentrated nitric acid, heat and stir until dissolved, then evaporate the solution to obtain white solid lutetium nitrate; (2) add 15g of ethanol, stir and dissolve the solid lutetium nitrate, and then add 0.0202g of cerium nitrate, then add 1g of polyvinyl butyral, and stir until a transparent viscous liquid; (3) Weigh 5g of tetraethyl orthosilicate, add it to the mixture of 5g of absolute ethanol and 1g of water, and then Add 0.1g of concentrated hydrochloric acid, stir for 2 hours, and mix well; (4) Mix the solution prepared in step (2) with the solution prepared in step (3), and stir for 2 hours to obtain the spinning stock solution; (5) Prepare the prepared Add the spinning stock solution into the syringe, adjust the spinning voltage to 12kV, the injection speed parameter is 5ml / h, the needle is No. 7 needle, the receiving device is a drum, the drum speed is 10m / min, the length of the cylinder is 300mm, and the diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com