A method of manufacturing a diamond film piston pin extrusion punch

A technology of diamond film and manufacturing method, applied in the direction of metal extrusion forming tools, metal extrusion, manufacturing tools, etc., can solve the problems of production line shutdown, economic loss, breakage, etc., and achieve improved service life and efficiency. The effect of continuous appearance and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Piston pin extrusion punch: diameter Ø20, total length 140mm, effective working length 90mm, of which the length of the extrusion part of the punch is 18 mm, material: YG8 solid carbide.

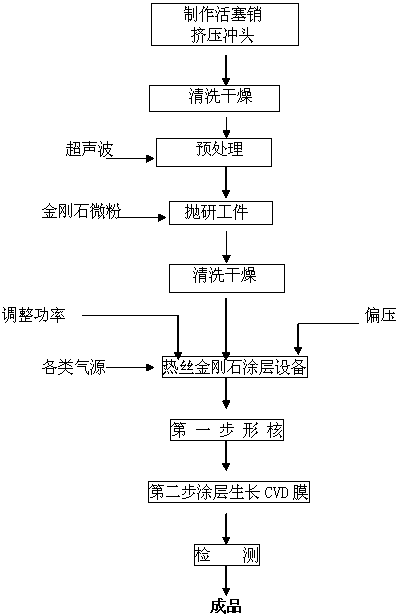

[0023] Such as figure 1 Shown, a kind of manufacturing method of diamond film piston pin extruding punch comprises the following steps:

[0024] 1. Grind the YG8 solid carbide piston pin extrusion punch (hereinafter referred to as "workpiece") according to the dimensional accuracy of the drawing;

[0025] 2. Use anhydrous ether (alcohol) to clean and remove the anti-rust oil on the surface of the workpiece, then put the cleaned workpiece into a constant temperature drying oven, and dry it within 1min, with the temperature controlled at 50°C;

[0026] 3. Use Na 2 FeO 4 , potassium hydroxide, and water are prepared into a pretreatment solution in a ratio of 1:2:20 by weight;

[0027] 4. Put the part of the workpiece with a working length of 90 mm into the pretreatment solution, plac...

Embodiment 2

[0036] Piston pin extrusion punch: diameter Ø18, total length 120mm, effective working length 70mm, of which the length of the extrusion part of the punch is 18 mm, material: YG8 solid carbide.

[0037] The steps to make the diamond film piston pin extrusion punch are as follows:

[0038] 1. Grind the YG8 solid carbide piston pin extrusion punch (hereinafter referred to as "workpiece") according to the dimensional accuracy of the drawing;

[0039] 2. Use anhydrous ether (alcohol) to clean and remove the anti-rust oil on the surface of the workpiece, then put the cleaned workpiece into a constant temperature drying oven and dry it within 1min, with the temperature controlled at 60°C;

[0040] 3. Use Na 2 FeO 4 , potassium hydroxide, and water are prepared into a pretreatment solution in a ratio of 1:2:20 by weight;

[0041] 4. Put the part of the workpiece with a working length of 90 mm into the pretreatment solution, place it in an ultrasonic cleaner, and vibrate for 60 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com