High-intensity magnetic field assisted pulsed laser deposition system

A pulsed laser deposition and auxiliary pulse technology, applied in ion implantation plating, coating, metal material coating process, etc. The effect of simple operation, stable and reliable work, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The preferred embodiment of the strong magnetic field assisted pulsed laser deposition system of the present invention is:

[0017] It includes a pulsed laser and a pulsed laser deposition columnar vacuum chamber, the pulsed laser deposition columnar vacuum chamber includes a double-layer jacketed cylindrical chamber with water cooling, and the double-layered jacketed cylindrical chamber is placed in the bore of a superconducting magnet;

[0018] The flange plate on one side of the double-jacketed columnar cavity is equipped with a substrate heating table or laser heating table and its rotating mechanism, and the flange plate on the other side of the double-layer jacketed columnar cavity is equipped with a target assembly and its A moving / rotating mechanism, the substrate heating table, the laser heating table and the target assembly are located in the middle of the strong magnetic field of the superconducting magnet;

[0019] The pulsed laser deposition columnar vacuum...

specific Embodiment 1

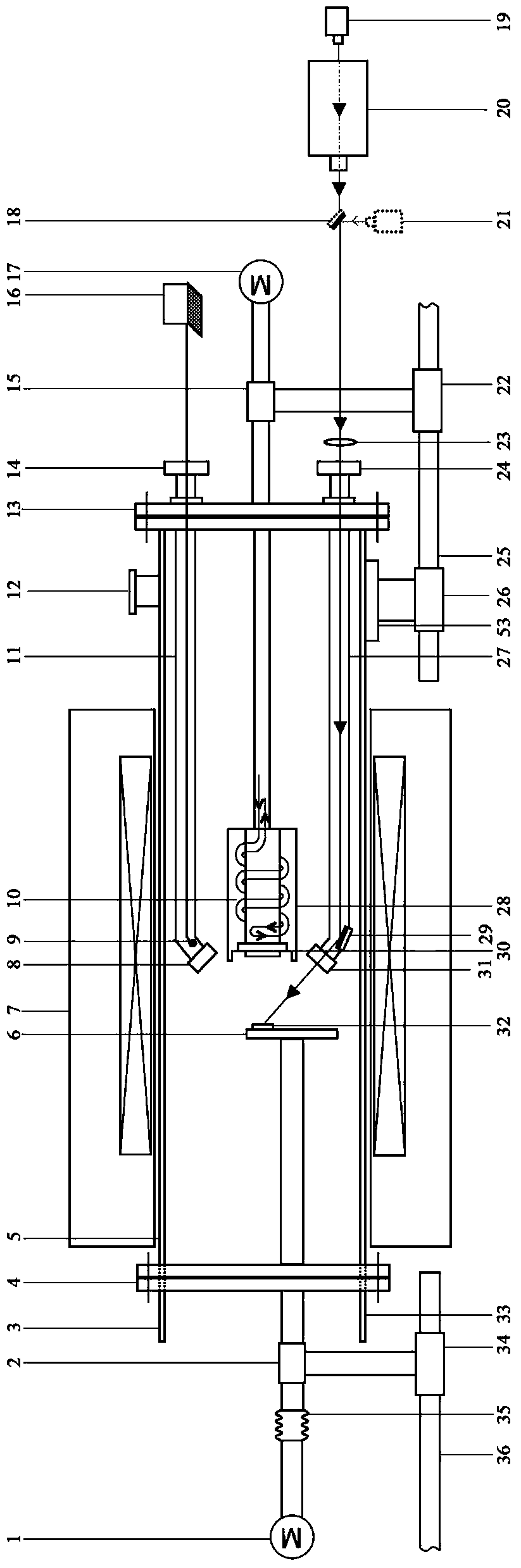

[0035] Such as figure 1 As shown, it consists of superconducting magnet 7, pulsed laser 20, pulsed laser deposition columnar vacuum chamber, high vacuum unit (not shown in the figure), gas flow control (not shown in the figure) and other parts. The pulsed laser deposition columnar vacuum chamber is placed horizontally, and the two ends are vacuum-tightly connected by flanges. It consists of three parts: a double-jacketed columnar chamber 5 with water cooling, and a flange 13 with a substrate heating table and a rotating mechanism. , the flange 4 with the target assembly and the moving / rotating mechanism, these three parts are fixed on the sliders 26, 22, 34 by the brackets 53, 15, 2 respectively, and the sliders 26, 22 are installed on the same group of guide rails 25, The slider 34 is installed on another set of guide rails 36, and the two sets of guide rails are fixed on the optical platform (not shown in the figure), and the three parts can move one-dimensionally on the gui...

specific Embodiment 2

[0042] In order to change the angle between the magnetic field and the heating stage (that is, the substrate surface on which the film grows), realize film growth and post-annealing treatment under different magnetic field orientations, so as to more effectively realize the regulation of the magnetic field on the microstructure and physical properties of film growth, for This needs to design a kind of more dexterous heating device. Such as figure 2 As shown, a design scheme of a laser heating table is given. Will figure 1 The flange plate 13 with the substrate heating table and the rotating mechanism in the middle is replaced with figure 2 The flange plate 44 with the laser heating table 38 in the middle can realize the growth of the strong magnetic field-assisted pulse laser deposition film and post-annealing treatment at different magnetic field orientations and higher temperatures. The airtight laser introduction chamber 50 and the vacuum-sealed video device introducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com