A kind of electrochemical method recycles the method for processing low cobalt WC-CO cemented carbide waste

A hard alloy, recycling technology, applied in the direction of optics, process efficiency improvement, photography technology, etc., can solve the problems of inability to judge and control electrochemical dissolution, high power consumption, weak basic research on tungsten hard gold alloy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

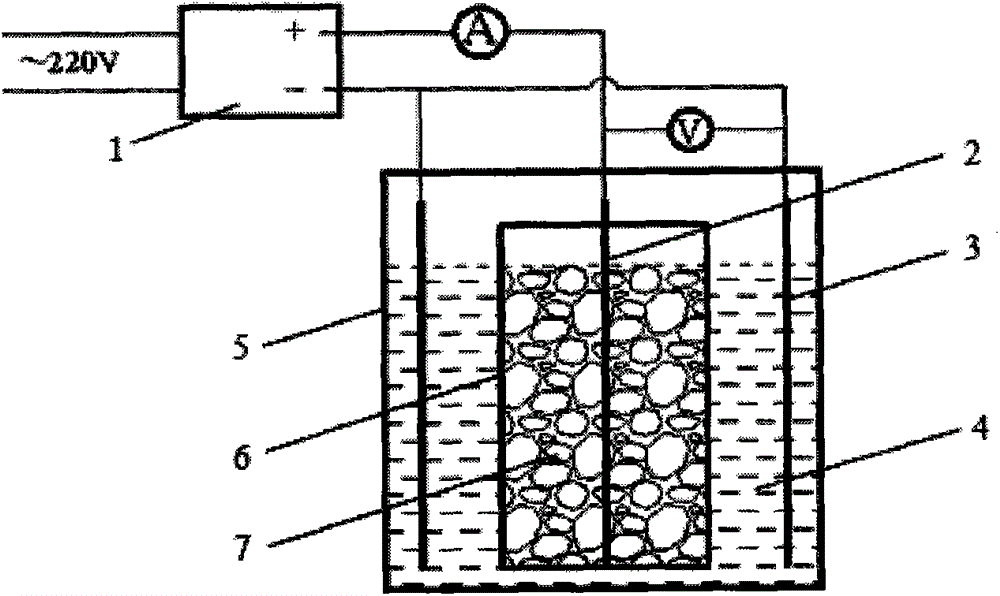

Method used

Image

Examples

Embodiment 1

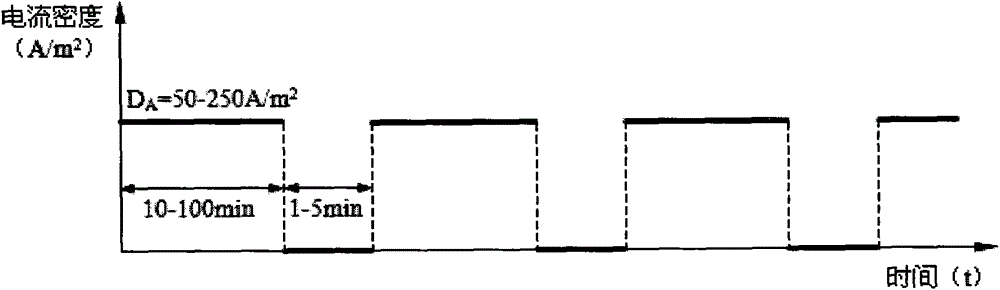

[0023] The processed tungsten hard gold alloy waste is cemented carbide with a metal cobalt content of 6%, and the waste is crushed to 10mm. The electrolyte composition is 0.5mol / LH 2 SO 4 , 10g / L of NaF; the electrode spacing d is 20mm, the electrolyte temperature T is 60°C, the ratio of the electrolyte circulation flow rate to the cross-sectional area of the electrolytic cell (called the circulation flow rate, the same below) is 20cm / min; continuous Electrolyze for 100min, stop for 3min. The experimental results show that according to the concentration of metal cobalt in the solution, the calculated current efficiency of cobalt electrolysis is 99.1%. Anode current density D A 200A / m 2 , running continuously for 24 hours, the electrolysis efficiency has no obvious change. The measured cell voltage is 1.26 volts, and the calculated power consumption is 1156Kwh / T cobalt.

Embodiment 2

[0025] The processed tungsten hard gold alloy waste is a cemented carbide with a metal cobalt content of 11%, and the waste is crushed to 12mm; the composition of the electrolyte is 0.5mol / LH 2 SO 4 , 10g / L NaF; electrode distance d is 20mm, electrolyte temperature T is 60°C, electrolyte circulation flow rate is 20cm / min; continuous electrolysis for 100min, stop for 3min. Experimental results show that the current efficiency of cobalt electrolysis is 99.5%. Anode current density D A 240A / m 2 , running continuously for 24 hours, the electrolysis efficiency has no obvious change. The measured cell voltage is 1.51 volts, and the calculated power consumption is 1380Kwh / T cobalt.

Embodiment 3

[0027] The processed tungsten hard gold alloy waste is a cemented carbide with a metal cobalt content of 11%, and the waste is crushed to 12mm; the composition of the electrolyte is 0.5mol / LH 2 SO 4 , no additives are used; the electrode distance d is 20mm, the electrolyte temperature T is 60°C, and the electrolyte circulation flow rate is 20cm / min. Continuous electrolysis for 100min, stop for 3min. Experimental results show that the current efficiency of cobalt electrolysis is 99.6%. Anode current density D A 150A / m 2, running continuously for 24 hours, the electrolysis efficiency has no obvious change. The measured cell voltage is 0.82 volts, and the calculated power consumption is 750Kwh / T cobalt. Further increase the current density to 175A / m 2 , after 90 minutes of electrolysis, the cell voltage rose sharply to 1.42 volts. It can be seen that without the use of additives, anode passivation is prone to occur at high current densities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com