A comprehensive treatment method for recovery and recycling of semi-coke wastewater with phenol and ammonia

A technology for the recovery of blue carbon wastewater and phenol ammonia, which is applied in the field of comprehensive recycling of phenol ammonia recovery from blue carbon wastewater, can solve the problems of poor system operation stability, influence system stability, and blockage of stripping trays, and ensure the Stability of water and operation, realization of resource recovery, and reduction of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

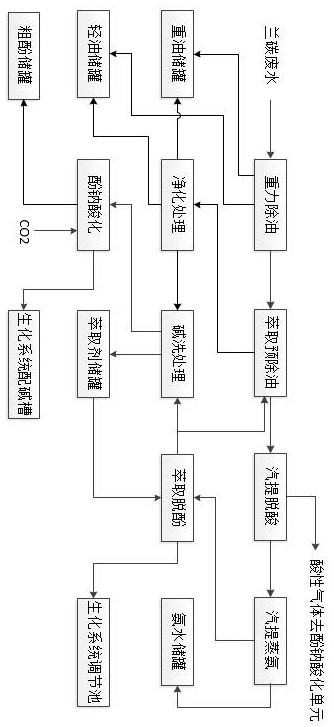

Method used

Image

Examples

Embodiment 1

[0033] The semi-coke wastewater to be treated is a semi-coke processing enterprise, which is the wastewater after deacidification, deamination and pre-oil removal. The main indicators are: COD: 10000mg / L; oil: 500mg / L; total phenols: 2000mg / L ; NH4-N: 1500mg / L; pH value: 7.5.

[0034] The actual waste water treatment process is as follows: the waste water is left to stand for 36 hours in the semi-coke waste water tank, and the standing waste water is sent to the pre-oil removal reactor after passing through the coke filter, and the extraction oil-water ratio in the pre-oil removal reactor is 1: 15. The waste water from the pre-oil removal reactor enters the stripping and deacidification tower, which is heated by low-pressure steam, the steam pressure is 0.2Mpa, and the temperature at the top of the deacidification tower is controlled at 55°C. The wastewater from the bottom of the deacidification tower enters the ammonia distillation tower, which is heated by low-pressure stea...

Embodiment 2

[0037] The semi-coke wastewater to be treated is a calcium carbide production enterprise, which is wastewater after deacidification, deamination and pre-oil removal. The main indicators are: COD: 40000mg / L; oil: 5000mg / L; total phenols: 15000mg / L; NH4-N: 3000mg / L; pH value: 9.

[0038] The actual process of wastewater treatment is as follows: the wastewater is allowed to stand for 72 hours in the semi-coke wastewater tank, and the wastewater is sent to the pre-degreasing reactor after being passed through the coke filter. The extraction oil-water ratio in the pre-oil removal reactor is 1:8. The waste water from the pre-oil removal reactor enters the stripping deacidification tower, which is heated by low-pressure steam, the steam pressure is 0.3Mpa, and the temperature at the top of the deacidification tower is controlled at 80°C. The wastewater from the bottom of the deacidification tower enters the ammonia distillation tower, which is heated by low-pressure steam with a ste...

Embodiment 3

[0041] The semi-coke wastewater to be treated is the wastewater after deacidification, deamination and pre-oil removal of a coal chemical enterprise. The main indicators are: COD: 25000mg / L; oil: 2500mg / L; total phenols: 10000mg / L; NH4-N: 4000mg / L; pH value: 8.7.

[0042] The actual process of wastewater treatment is as follows: the wastewater is allowed to stand for 72 hours in the semi-coke wastewater tank, and the wastewater is sent to the pre-degreasing reactor after being passed through the coke filter. The extraction oil-water ratio in the pre-oil removal reactor is 1:10. The waste water from the pre-oil removal reactor enters the stripping deacidification tower, which is heated by low-pressure steam, the steam pressure is 0.3Mpa, and the temperature at the top of the deacidification tower is controlled at 80°C. The wastewater from the bottom of the deacidification tower enters the ammonia distillation tower, which is heated by low-pressure steam with a steam pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com