A method for removing cadmium

A copper-cadmium slag and high-grade technology, which is applied in the field of wet zinc smelting, can solve problems such as excessive consumption of zinc powder, poor purification and removal of cadmium, and imbalanced ratio of copper and cadmium to achieve the problem of imbalanced copper-cadmium ratio and copper-cadmium slag ratio. The effect of reducing and increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

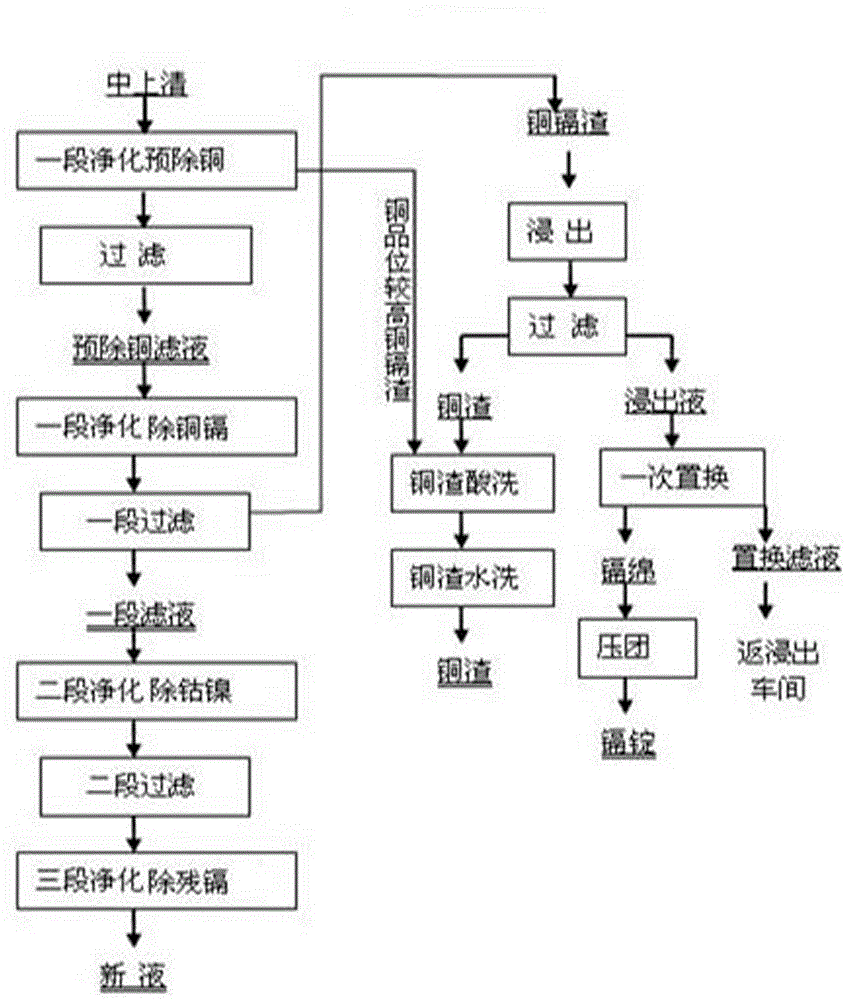

Image

Examples

Embodiment 1

[0028] (1) One-stage purification and pre-removal of copper

[0029] In copper 1.3kg / m 3 , containing cadmium 0.4kg / m 3 Add 80 mesh 2.4kg / m 3 The coarse zinc powder pre-removes copper until the ratio of copper ions to cadmium ions in the liquid is 1:3.5, and the copper-cadmium slag and pre-removal of copper containing 33% copper and 2.5% cadmium are obtained by filtration. filtrate.

[0030] (2) One-stage purification to remove copper and cadmium

[0031] in step Add 200 mesh 0.8kg / m to the obtained pre-copper removal filtrate 3 The blown zinc powder continues to remove copper and cadmium, and after filtration, copper cadmium slag with a copper content of 4.8% and a cadmium content of 16.7% is obtained. Copper cadmium slag with a high cadmium grade and a section of filtrate are obtained. The slag and leachate are replaced once to obtain cadmium cotton and the replacement filtrate, and the cadmium cotton is pressed to obtain cadmium ingots, and the replacement filtrate i...

Embodiment 2

[0040] (1) One-stage purification and pre-removal of copper

[0041] In copper 0.4kg / m 3 , containing cadmium 0.8kg / m 3 Add 0.3kg / m of 60 mesh Zhanzhong supernatant to the supernatant 3 The coarse zinc powder pre-removes copper until the ratio of copper ions to cadmium ions in the supernatant is 1:2.5, and the copper-cadmium slag and the pre-copper cadmium slag with a copper mass fraction of 28% and a cadmium content of 9.7% are obtained by filtering. Decopper filtrate.

[0042] (2) One-stage purification to remove copper and cadmium

[0043] in step Add 150 mesh 1.6kg / m to the obtained pre-copper removal filtrate 3 The blown zinc powder continues to remove copper and cadmium. After filtration, the copper-cadmium slag with a copper mass fraction of 5.3% and a cadmium content of 15.8% and a high-grade copper-cadmium slag and a filtrate are obtained. The obtained copper-cadmium slag is leached, Filter to obtain copper slag and leaching solution, replace the leaching solut...

Embodiment 3

[0052] (1) One-stage purification and pre-removal of copper

[0053] In copper 0.6kg / m 3 , containing cadmium 0.6kg / m 3 First add 0.7kg / m of 80 mesh Zhanzhong supernatant to the supernatant 3 Pre-removal of copper with coarse zinc powder, until the ratio of copper ions to cadmium ions in the liquid is 1:3, and filter to obtain copper-cadmium slag with a copper content of 30% and a cadmium content of 6.5% and a copper-cadmium slag with a high copper grade and a low cadmium grade and pre-removal of copper filtrate.

[0054] (2) One-stage purification to remove copper and cadmium

[0055] in step Add 180 mesh 1.2kg / m to the obtained pre-copper removal filtrate 3 Blowing zinc powder continues to remove copper and cadmium, and after filtration, obtain a copper-cadmium slag with a copper mass percentage of 6.4% and a cadmium content of 16.1%. To obtain copper slag and leachate, replace the leachate once, obtain cadmium cotton and replace the filtrate, press the cadmium cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com