Adhesive and preparation method thereof as well as preparation technology of halogen-free aluminium base copper-clad plate based on adhesive

An aluminum-based copper clad laminate and adhesive technology, applied in the directions of adhesives, adhesive types, chemical instruments and methods, etc., can solve the problems of poor insulation layer reliability, poor heat resistance, and difficulty in increasing the amount of filler added to achieve insulation. Excellent reliability, broad market prospects, and the effect of increasing the addition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also proposes a kind of preparation method of adhesive, comprises the following steps:

[0024] 1) Proportion and pretreatment of inorganic fillers

[0025] Compound one or more inorganic fillers among alumina, aluminum nitride, and boron nitride, and select spherical fillers and irregular fillers to cooperate with each other. The large particle size, medium particle size and small particle size are combined with each other. The D50 with a diameter of 9-15 microns is used for fillers, the D50 with a medium particle size is 4-6 microns, and the D50 with a small particle size is 0.5-2 microns. The weight percentage of large, medium and small fillers in the glue system is 75-81%, add a mixed solution of KH560 and propylene glycol methyl ether with a weight ratio of 1-2% of the glue system to the above filler, and treat it in a ball mill for 2-4 hours. Mix well and mix well.

[0026] 2) Add rubber-modified epoxy resin to improve the toughness of the ...

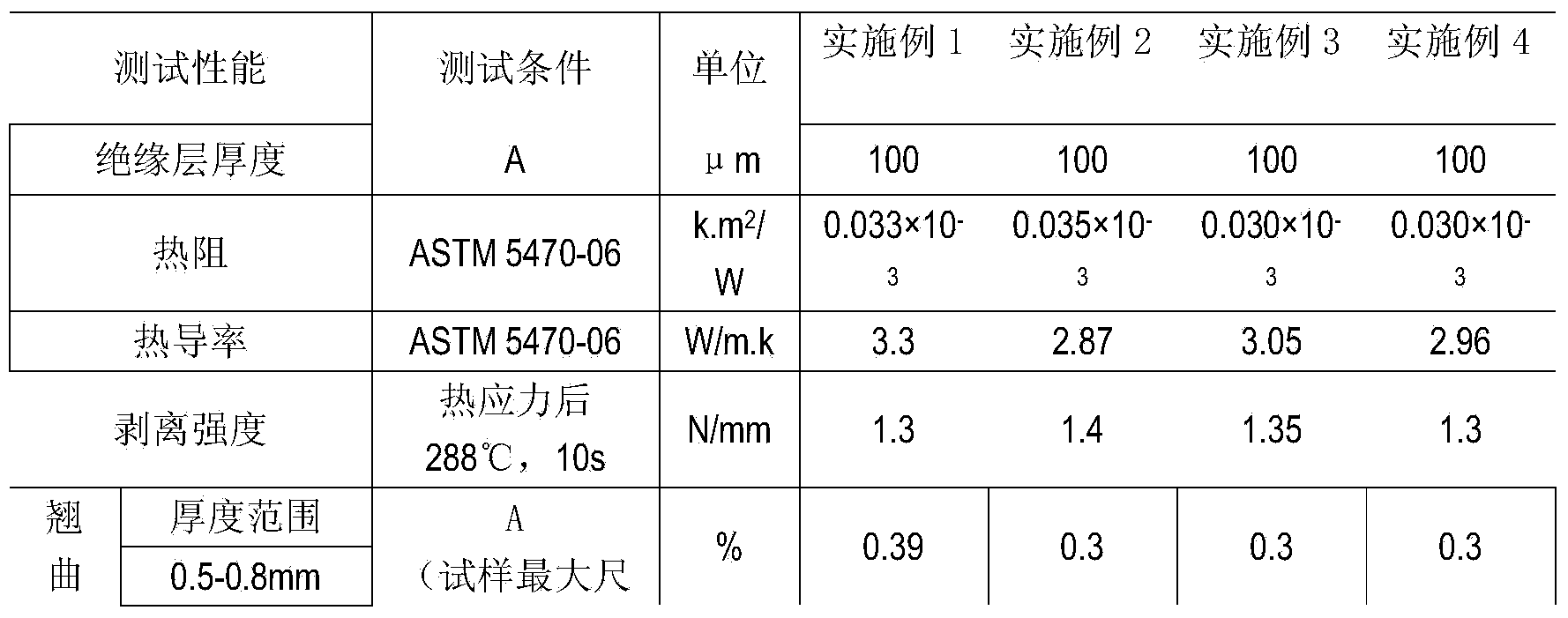

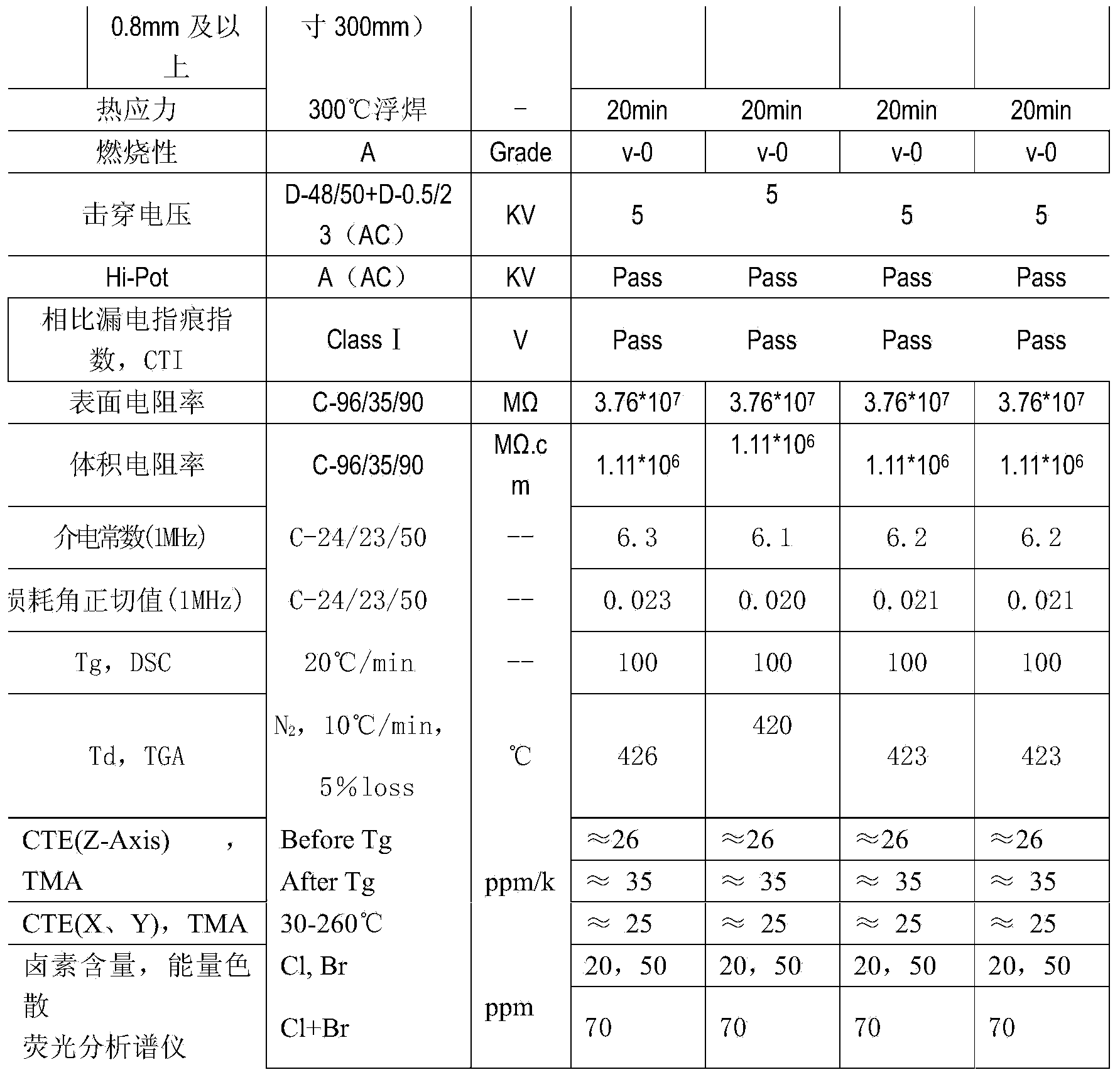

Embodiment 1

[0034] The composition and mass percentage of the insulating layer of the aluminum-based copper-clad laminate in this example: phosphorus-containing epoxy resin, rubber-toughened epoxy resin are 7-10%, 4-10%, novolac resin 2-4%, and propylene glycol methyl Dissolve 0.01-0.03% of diphenylimidazole or diethylimidazole in ether, use a ball mill to process the mixture of D504-6 micron 75% spherical AlN and 0.5-1% KH560 and propylene glycol methyl ether for 2-4h, and the rest is solvent; The two materials are mixed together and stirred by vacuum heating to make epoxy resin adhesive.

[0035] The manufacturing process of aluminum-based copper clad laminates, the steps are:

[0036] a. Dry non-woven grinding on the aluminum plate, the surface roughness of the polished aluminum plate is controlled at Ra0.5-1.0, Rz3.0-5.0;

[0037] b. Coat the adhesive on the surface of the aluminum plate by screen printing, and pre-cure the insulating coating by infrared heating. The oven temperature...

Embodiment 2

[0040] The composition and mass percentage of the insulating layer of the aluminum-based copper-clad laminate in this example: phosphorus-containing epoxy resin, rubber-toughened epoxy resin are 7-10%, 4-10%, novolac resin 2-4%, and propylene glycol methyl Ether dissolve diphenylimidazole or diethylimidazole 0.01-0.03%, use ball mill to process D509-15 micron 60% irregular Al 2 o 3 , D504-6 micron spherical mixture of 21% AlN and 0.5-1% KH560 and propylene glycol methyl ether for 2-4h, and the rest is a solvent; mix various materials together and stir them by vacuum heating to make epoxy resin adhesive.

[0041] The manufacturing process of aluminum-based copper clad laminates, the steps are:

[0042] a. Degrease, polish and anodize the aluminum plate;

[0043] b. Coat the adhesive on the surface of the aluminum plate by screen printing, and pre-cure the insulating coating by infrared heating. The oven temperature is set in sections: 120-140°C; 140-160°C; 160-180°C ; 140-150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com