Bismuth ferrite nano-cylinder and preparation method thereof

A technology of bismuth ferrite and cylinders, which is applied in the field of bismuth ferrite nano cylinders and its preparation, can solve the problems of powder particle agglomeration and impurity, and achieve the effects of low cost, low requirements for experimental equipment, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

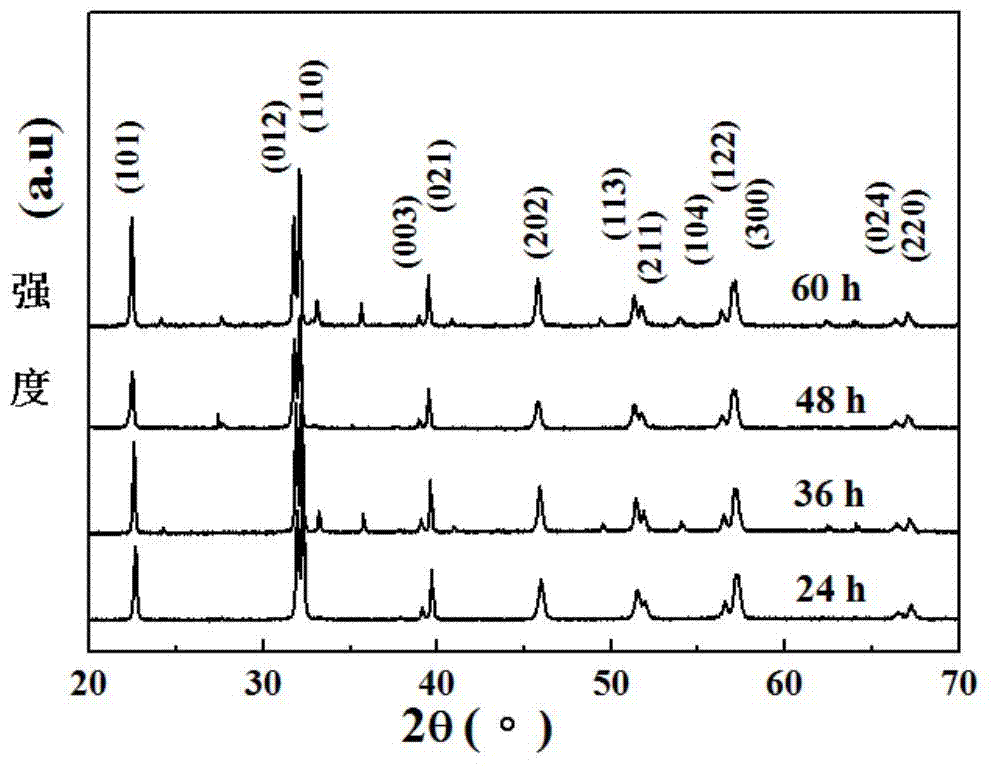

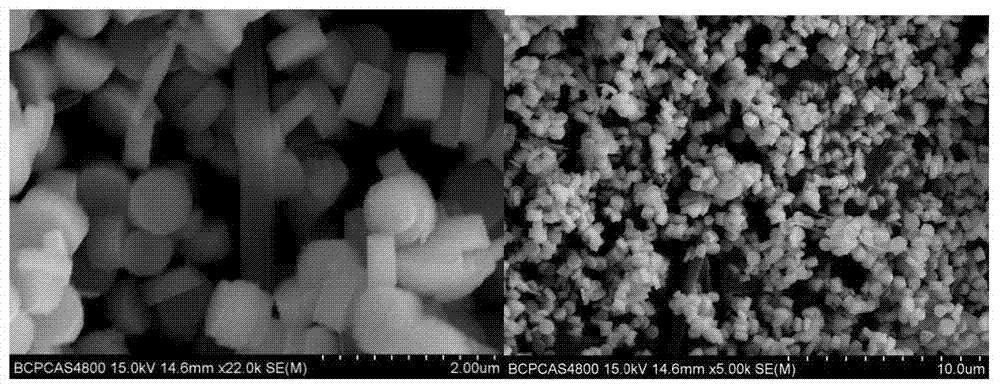

[0026] 1) According to the chemical formula of bismuth ferrite BiFeO 3 Measure and weigh bismuth nitrate and ferric nitrate, then add them to the liner of the polytetrafluoroethylene reactor, add deionized water according to the filling degree of 50%-80%, the molar volume fraction of bismuth ferrite is 0.02mol / L, magnetically stir 0.5-1 hour;

[0027] 2) Slowly add sodium hydroxide into the polytetrafluoroethylene reactor liner in step 1) while stirring, the molar volume fraction of sodium hydroxide is 1mol / L, and magnetically stir for 10-30 minutes;

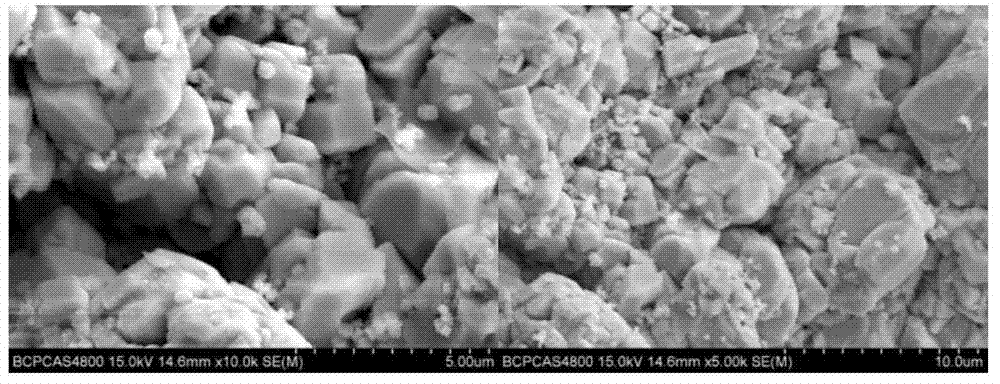

[0028] 3) Seal the liner of the polytetrafluoroethylene reactor in a stainless steel reactor, conduct a hydrothermal reaction at 130°C, keep it warm for 24 hours, cool it down to room temperature naturally, take out the reaction product, and alternately ultrasonicate it with deionized water and absolute ethanol After cleaning for several times, it is dried in an oven at 60-100° C. to obtain bismuth ferrite nano cylinders.

Embodiment 2

[0030] 1) According to the chemical formula of bismuth ferrite BiFeO 3 Measure and weigh bismuth nitrate and ferric nitrate, then add them to the liner of the polytetrafluoroethylene reactor, add deionized water according to the filling degree of 50%-80%, the molar volume fraction of bismuth ferrite is 0.1mol / L, magnetically stir 0.5-1 hour;

[0031] 2) Slowly add sodium hydroxide into the polytetrafluoroethylene reactor liner in step 1) while stirring, the molar volume fraction of sodium hydroxide is 5mol / L, and magnetically stir for 10-30 minutes;

[0032] 3) Seal the liner of the polytetrafluoroethylene reactor in a stainless steel reactor, conduct a hydrothermal reaction at 180°C, keep it warm for 48 hours, cool it down to room temperature naturally, take out the reaction product, and alternately ultrasonicate it with deionized water and absolute ethanol After cleaning for several times, it is dried in an oven at 60-100° C. to obtain bismuth ferrite nano cylinders.

Embodiment 3

[0034] 1) According to the chemical formula of bismuth ferrite BiFeO 3 Measure and weigh bismuth nitrate and ferric nitrate, then add them to the liner of the polytetrafluoroethylene reactor, add deionized water according to the filling degree of 50%-80%, the molar volume fraction of bismuth ferrite is 0.03mol / L, magnetically stir 0.5-1 hour;

[0035] 2) Slowly add sodium hydroxide into the polytetrafluoroethylene reactor liner in step 1) while stirring, the molar volume fraction of sodium hydroxide is 2mol / L, and magnetically stir for 10-30 minutes;

[0036] 3) Seal the liner of the polytetrafluoroethylene reactor in a stainless steel reactor, conduct a hydrothermal reaction at 150°C, keep it warm for 36 hours, cool it down to room temperature naturally, take out the reaction product, and alternately ultrasonicate it with deionized water and absolute ethanol After cleaning for several times, it is dried in an oven at 60-100° C. to obtain bismuth ferrite nano cylinders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com