Safe non-aqueous electrolyte for battery

A non-aqueous electrolyte, safe technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of high freezing point, affecting the low-temperature performance of the battery, and reducing the conductivity, so as to achieve improved low-temperature performance, excellent safety performance, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

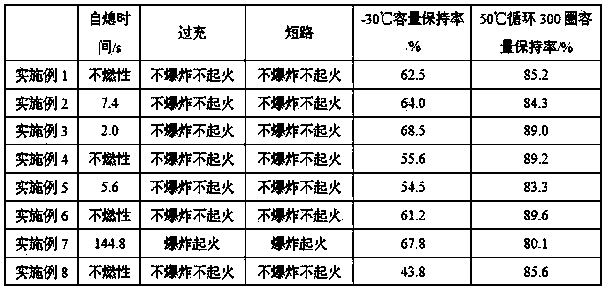

Examples

Embodiment 1

[0021] The electrolyte composition is as follows: Lithium salt LiPF 6 Mass concentration 1.0mol·L -1 , organic solvent propylene carbonate, cyclic phosphazene compound represented by structural formula (I) (wherein R 1 ~R 5 is fluorine, R 6 Ethoxy) and diethyl carbonate (mass ratio 20:20:60), the additive vinyl vinyl sulfite (VES) accounts for 3% of the total mass of the electrolyte, and the additive VC accounts for 2% of the total mass of the electrolyte.

[0022] The prepared electrolyte is injected into the positive electrode according to the conventional battery manufacturing process. Lithium cobaltate , Negative pole graphite flexible packaging battery. The battery design capacity is 1000mAh. The battery is formed according to the following process: 0.02C constant current charging to 2.8V, 0.05C constant current charging to 3.3 V, 0.1C constant current charging to 4.2 V, 4.2 V constant voltage charging, cut-off current 0.033 c. After the formation, the battery i...

Embodiment 2

[0035] The electrolyte composition is as follows: Lithium salt LiPF 6 Concentration 1.0 mol·L -1 , organic solvent propylene carbonate, cyclic phosphazene compound represented by general formula (I) (wherein R 1 ~R 5 is fluorine, R 6 methoxy) and diethyl carbonate (mass ratio 25:5:70), the additive vinyl vinyl sulfite (VES) accounted for 3% of the total electrolyte, and the additive VC accounted for the total electrolyte The mass percentage of the amount is 2%.

Embodiment 3

[0037] The electrolyte composition is as follows: Lithium salt LiPF 6 concentration 0.8 mol L -1 , organic solvent propylene carbonate, cyclic phosphazene compound represented by general formula (I) (wherein R 1 ~R 6 Fluorine) and diethyl carbonate (mass ratio 20:10:70), the additive vinyl vinyl sulfite (VES) accounted for 3% of the total electrolyte, the additive VC accounted for 3% of the total electrolyte The mass percentage content is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com