Composite steel-plastic pressure tube and manufacturing method thereof

A steel-plastic composite and pressure pipe technology, applied to pipes, rigid pipes, tubular objects, etc., can solve the problems of reduced pressure bearing capacity, waste, and reduced metal utilization of pipes, so as to avoid the growth of microorganisms and water pollution , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

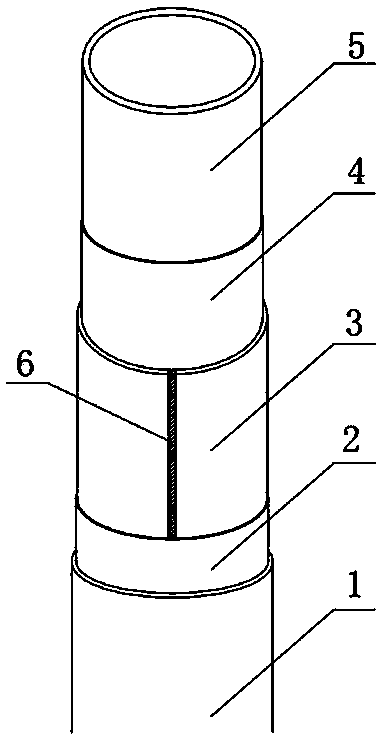

[0030] Example 1, such as figure 1 As shown, a steel-plastic composite pressure pipe includes an outer plastic layer 1, an outer rubber layer 2, an inner rubber layer 4 and an inner plastic layer 5, and is characterized in that: between the outer rubber layer 2 and the inner rubber layer 4 is A steel pipe 3 with a rough surface; the thickness of the weld 6 on the steel pipe 3 is 4% thicker than that of the steel pipe 3;

[0031] The surface roughness of the steel pipe 3 is Ra12.5;

[0032] The outer plastic layer 1 and the inner plastic layer 5 are polyethylene;

[0033] The outer rubber layer 2 and the inner rubber layer 4 are ethylene copolymer hot melt adhesives.

[0034] The manufacturing steps of the above-mentioned steel-plastic composite pressure pipe are as follows:

[0035] 1) Use laser textured rollers to roll and texturize the steel plate used to form a rough surface on the steel plate;

[0036] 2) Process the steel plate into a steel strip of the required width...

Embodiment 2~12

[0042] Embodiments 2 to 12 differ from Example 1 in that the materials of the inner and outer plastic layers and the inner and outer rubber layers, the surface roughness of the steel pipe and the thickening of the weld seam, the materials of the inner and outer plastic layers and the inner and outer rubber layers, and the rough surface of the steel pipe The thickness, weld thickness and performance parameters are shown in Table 1.

[0043] Table 1 Performance parameters of steel-plastic composite pressure pipe

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com