An optical fiber manufacturing process

A manufacturing process and technology of optical fibers, applied in the field of optical communication, can solve the problems of concave optical fibers and protruding end faces of ceramic ferrules, and achieve the effects of uniform and full glue, improved bonding strength, and increased effective bonding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

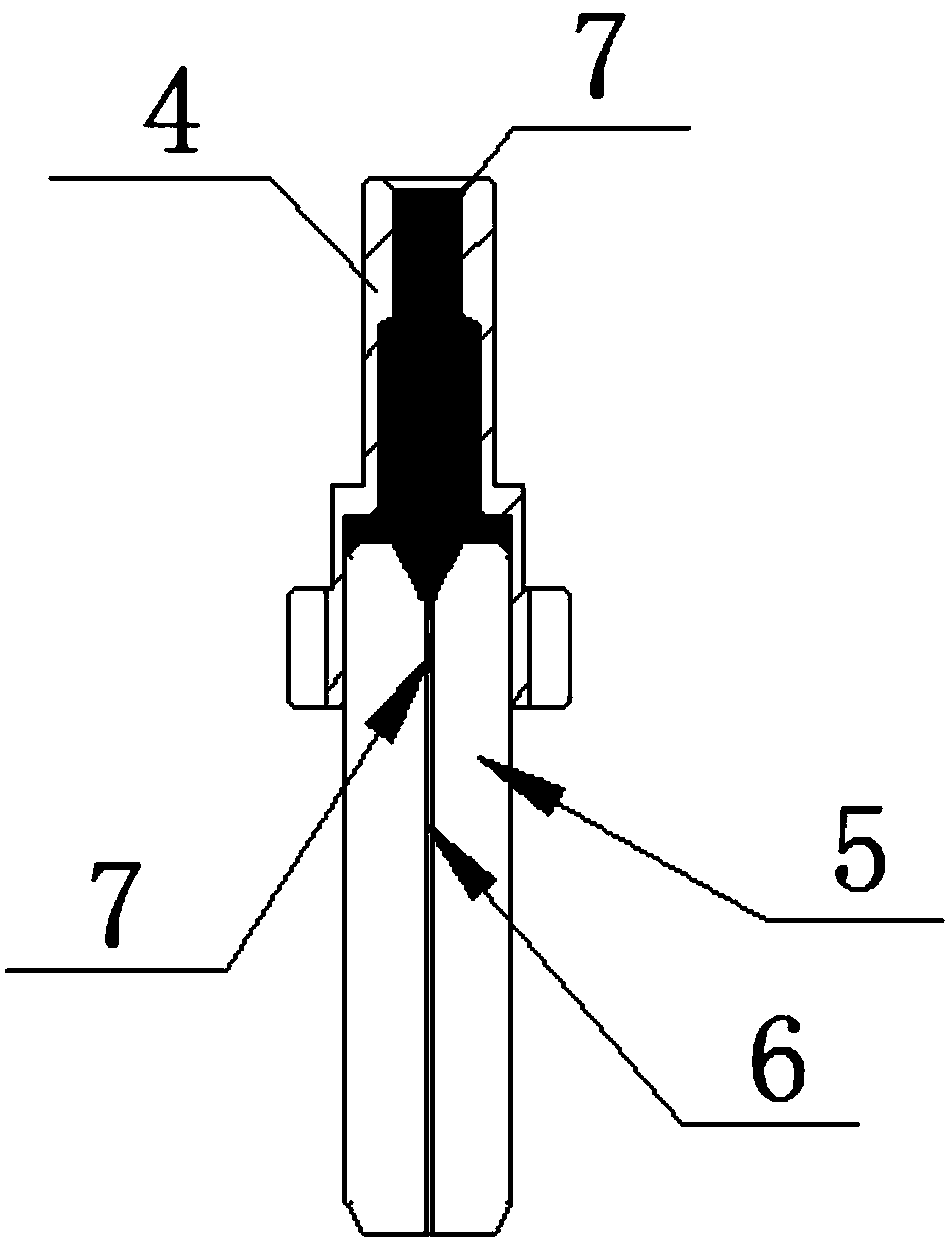

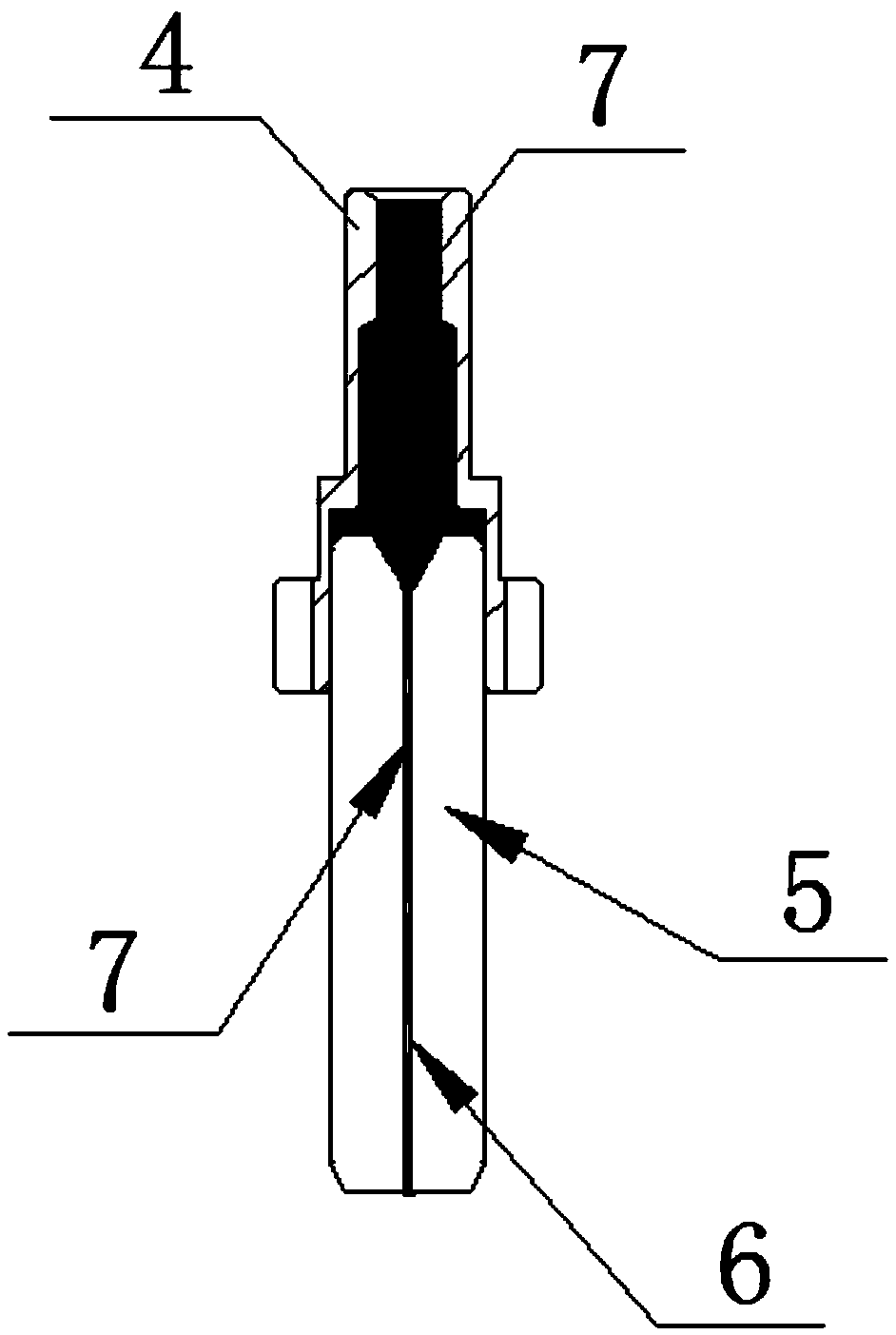

[0038] like Figure 1-4 As shown, an optical fiber manufacturing process includes the following steps:

[0039] a. Cutting steps: cut the optical cable of the specified length;

[0040] b. Pretreatment step: the pretreatment step includes the step of drying the wire, the step of pressing the wire, and the step of peeling in sequence,

[0041] Drying step: bake the optical cable obtained in step a at high temperature, and then fully cool it at room temperature; in the drying step, the optical cable with the shrinkage rate of the outer sheath 1 material >1‰ is baked at a high temperature of 120 ° C for 6 hours, and the cooling time is 2.5 hours are handled;

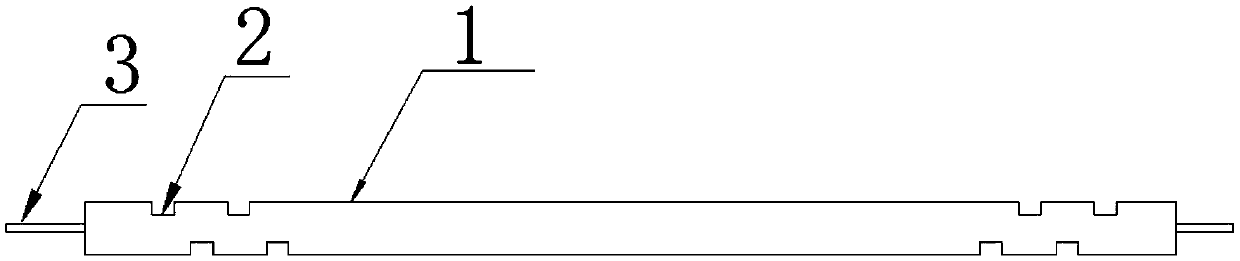

[0042] Crimping step: Add zigzag indentation to the surface of the outer sheath 1 of the optical cable after the drying step, see figure 1 , using a wire crimping machine to press out four pits 2 on the outer sheath 1, the four pits 2 are evenly distributed on the upper and lower parts of the optical cable sheath 1, and ...

Embodiment 2

[0050] like Figure 1-4 As shown, an optical fiber manufacturing process includes the following steps:

[0051] a. Cutting steps: cut the optical cable of the specified length;

[0052] b. Pretreatment step: the pretreatment step includes the step of drying the wire, the step of pressing the wire, and the step of peeling in sequence,

[0053] Drying step: bake the optical cable obtained in step a at high temperature, and then fully cool it at room temperature; in the drying step, the optical cable with the shrinkage rate of the outer sheath 1 material ≤ 1‰ is baked at a high temperature of 95°C for 6 hours, and the cooling time is 3.5 hours are handled;

[0054] Crimping step: Add zigzag indentation to the surface of the outer sheath 1 of the optical cable after the drying step, see figure 1 , using a wire crimping machine to press out four pits 2 on the outer sheath 1, the four pits 2 are evenly distributed on the upper and lower parts of the optical cable sheath 1, and th...

Embodiment 3

[0062] like Figure 1-4 As shown, an optical fiber manufacturing process includes the following steps:

[0063] a. Cutting steps: cut the optical cable of the specified length;

[0064] b. Pretreatment step: the pretreatment step includes the step of drying the wire, the step of pressing the wire, and the step of peeling in sequence,

[0065] Drying step: bake the optical cable obtained in step a at high temperature, and then fully cool it at room temperature; in the drying step, the optical cable with the shrinkage rate of the outer skin 1 material >1‰ is baked at a high temperature of 120 ° C for 6 hours, and the cooling time is 3.5 hours are handled;

[0066] Crimping step: Add zigzag indentation to the surface of the outer sheath 1 of the optical cable after the drying step, see figure 1 , using a wire crimping machine to press out four pits 2 on the outer sheath 1, the four pits 2 are evenly distributed on the upper and lower parts of the optical cable sheath 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com