A radial adjustment and fastening device for processing ultra-precision optical grazing incidence mirrors

A reflective mirror, ultra-precise technology, applied to the device and coating of the surface coating liquid, can solve the problems of the adhesion between the knife lens and the fastening seat, the decrease of the mirror surface precision, and the lens sinking, etc., to increase the The effective bonding area, improving the bonding force, and solving the effect of mirror surface shape error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

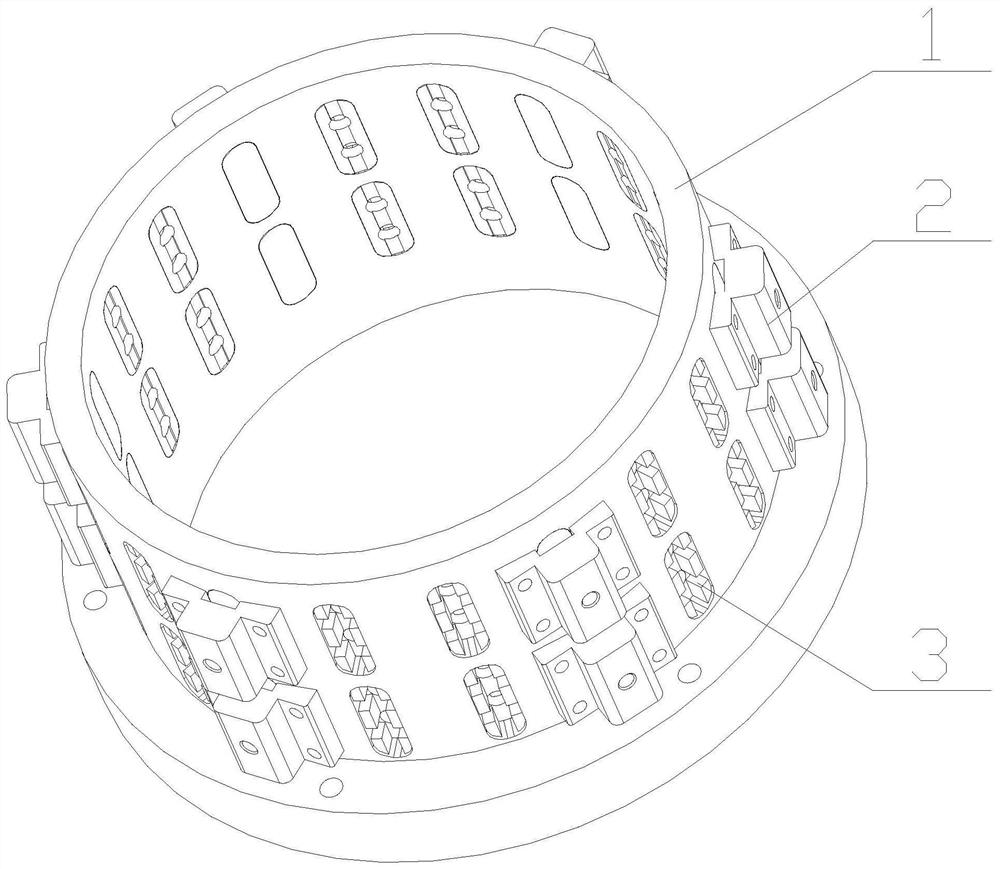

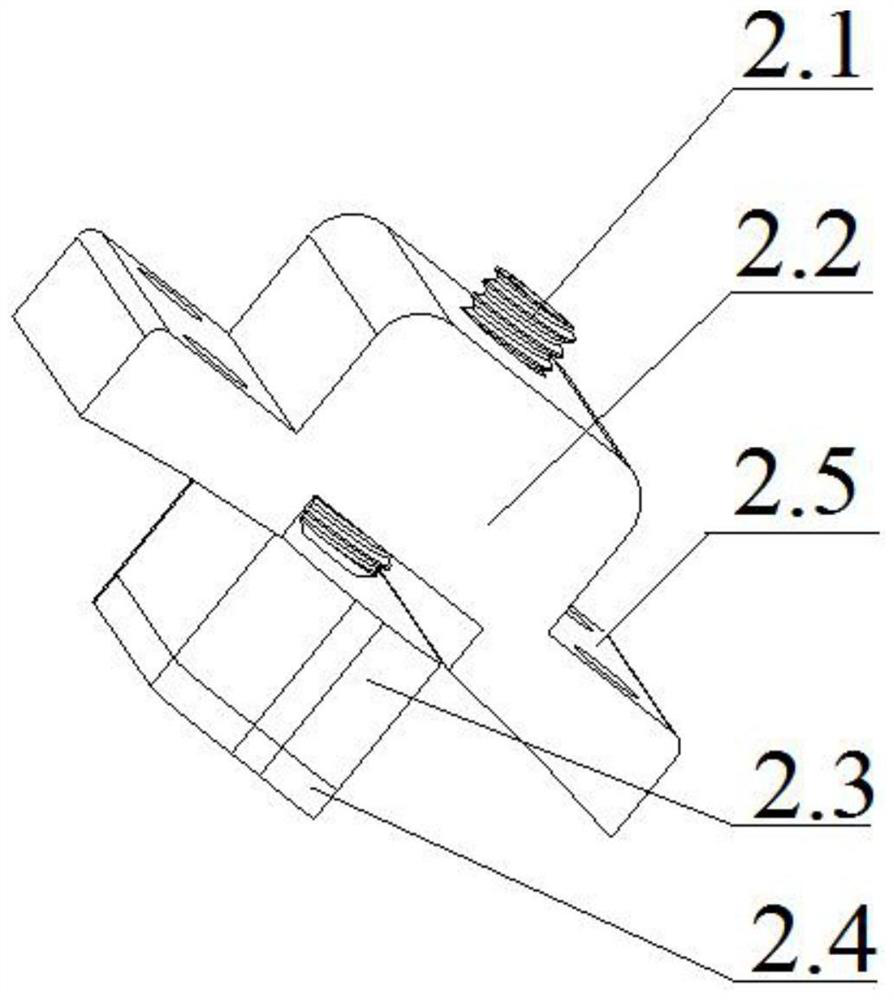

[0044] Such as Figure 1 to Figure 4 As shown, an ultra-precision optical grazing incidence mirror processing radial adjustment and fastening device of the present invention mainly includes: a fastening seat 1, a plurality of radial adjustment mechanisms 2 and a plurality of solid glue blocks 3; The adjustment mechanism 2 and a plurality of solid glue blocks 3 are installed on the fastening seat 1, and the reflector is installed in the fastening seat 1, wherein the radial adjustment mechanism 2 is used to adjust the radial direction of the reflector in the fastening seat 1. position, the solid glue block 3 is used to adjust the circumferential position of the reflector in the fastening seat 1 .

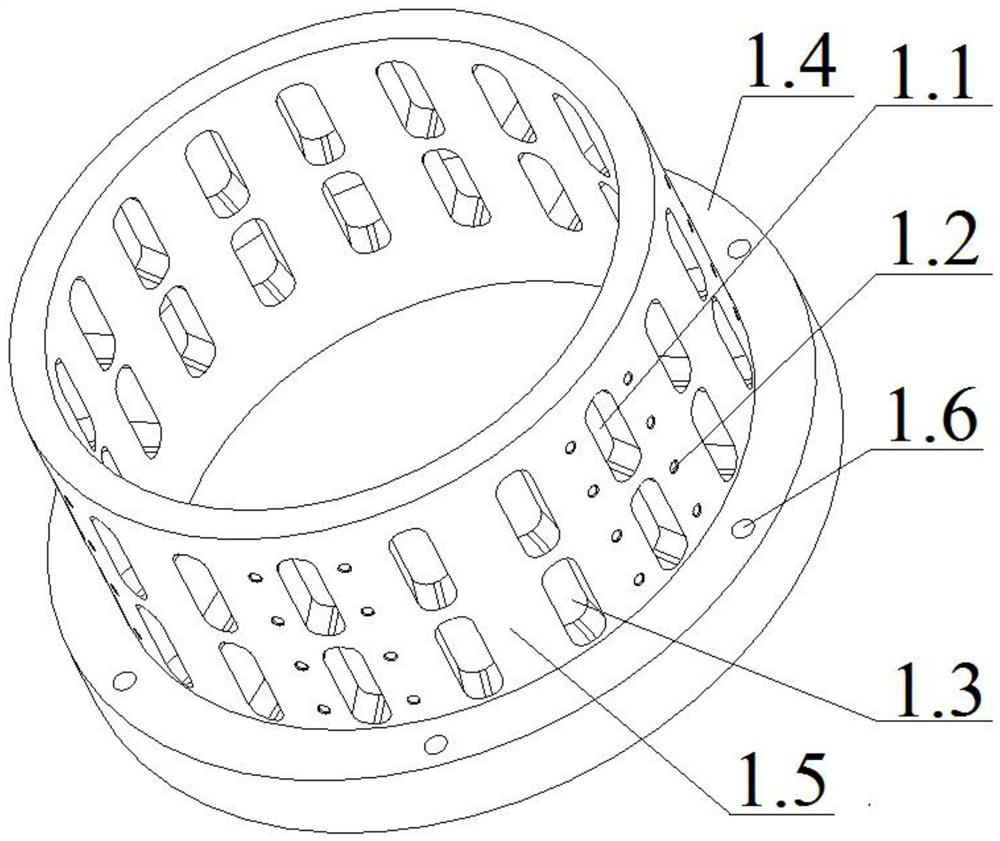

[0045] Such as figure 2 As shown, the fastening seat 1 mainly includes an annular chassis 1.4 and a hollow cylinder 1.5, the annular chassis 1.4 is fixed at the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com