Radial adjusting and fastening device for ultra-precision optical machining of grazing incidence mirror

A reflective mirror, ultra-precise technology, applied to the surface coating device, coating, etc., can solve the problems of the adhesion between the knife lens and the fastening seat, the decrease of the mirror surface precision, and the lens sinking, etc., to increase the The effective bonding area, improving the bonding force, and solving the effect of mirror surface shape error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further described in detail below in conjunction with the drawings.

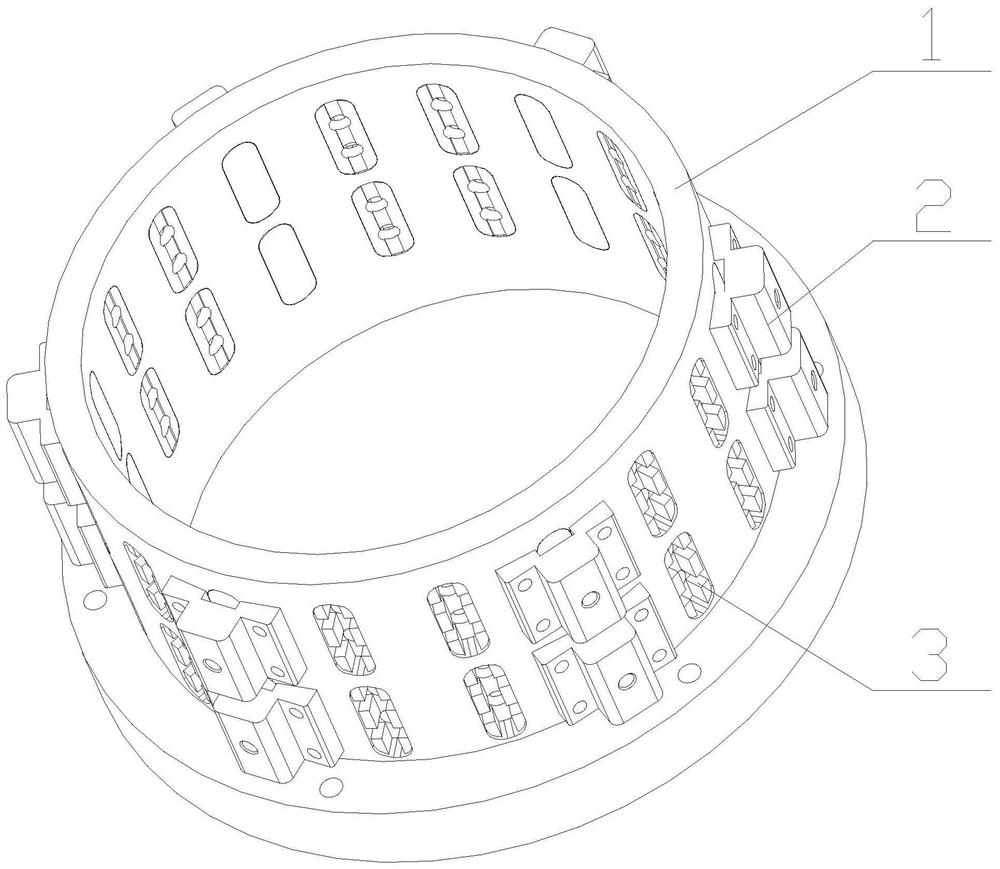

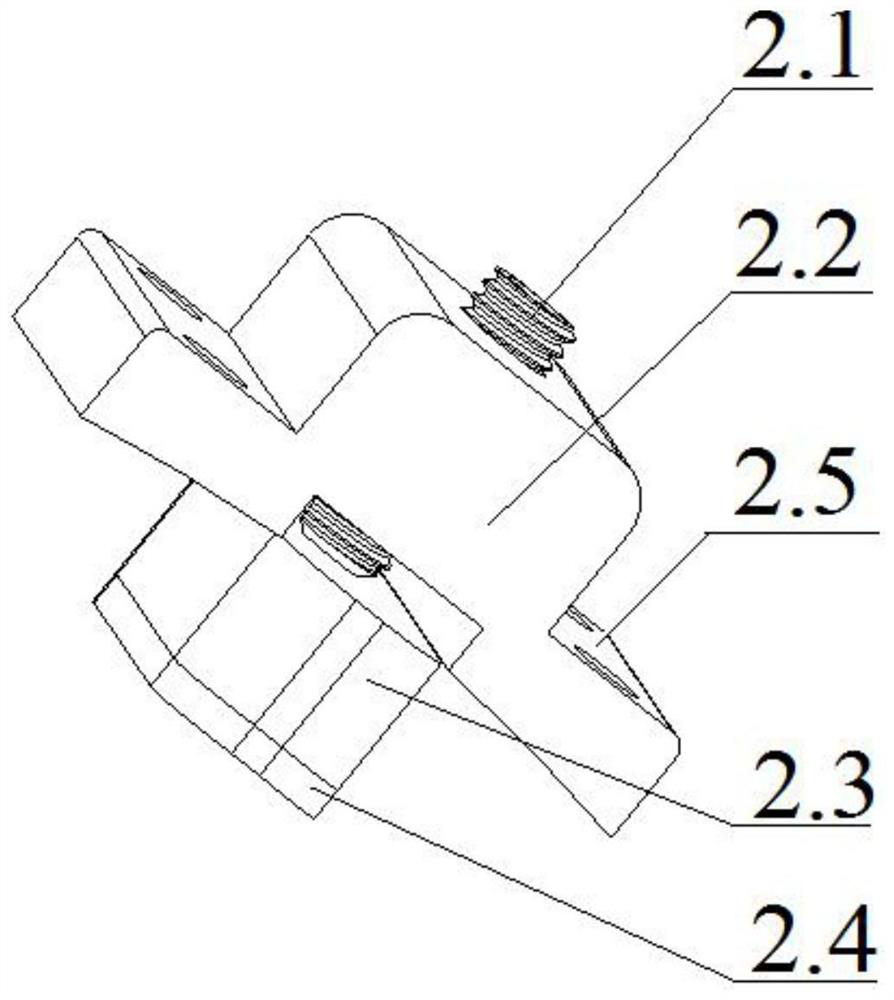

[0044]Such asFigure 1 to Figure 4As shown, an ultra-precision optical grazing incidence mirror processing radial adjustment and fastening device of the present invention mainly includes: a fastening seat 1, a plurality of radial adjustment mechanisms 2 and a plurality of glue blocks 3; The adjustment mechanism 2 and a plurality of glue blocks 3 are all installed on the fixing seat 1, and the reflector is installed in the fixing seat 1. The radial adjustment mechanism 2 is used to adjust the radial direction of the reflector in the fixing seat 1. Position, the glue block 3 is used to adjust the circumferential position of the reflector in the fixing seat 1.

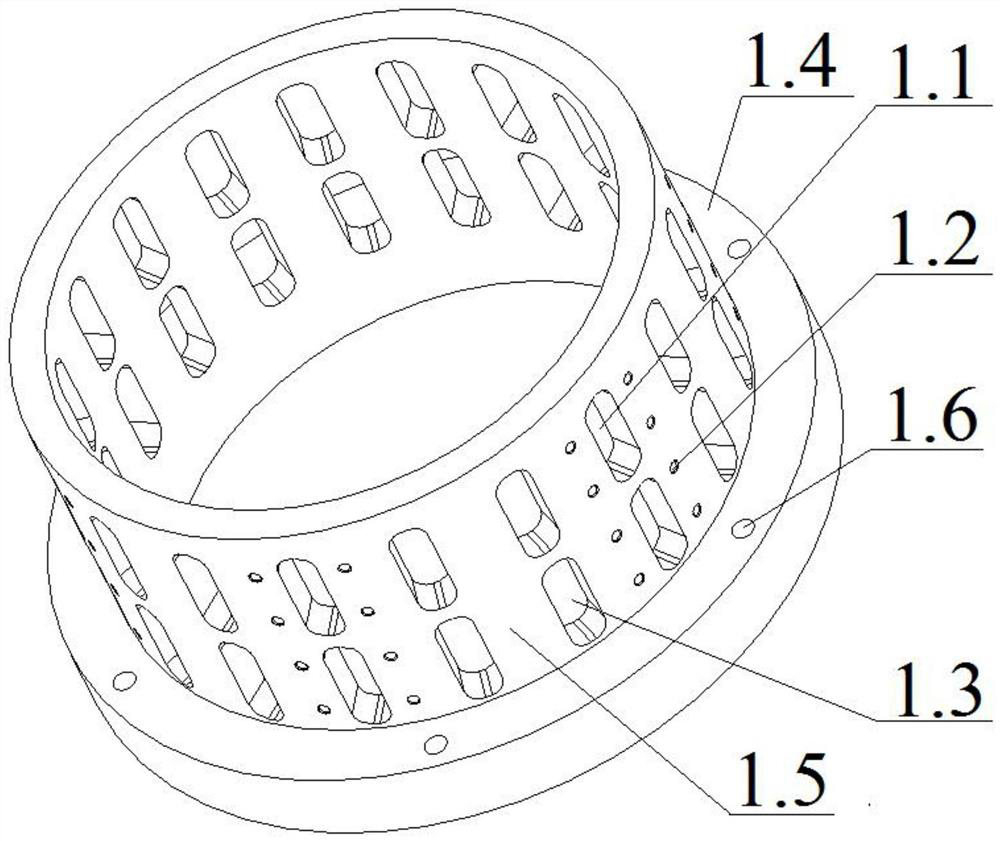

[0045]Such asfigure 2 As shown, the fastening seat 1 mainly includes an annular chassis 1.4 and a hollow cylinder 1.5. The annular chassis 1.4 is fixed at the lower end of the hollow cylinder 1.5. The inner wall of the annular bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com