Method for raising hot pressing bonding rate of PMMA micro fluidic chip formed by injection moulding

A microfluidic chip and thermocompression bonding technology, applied in the field of micromanufacturing, can solve the problems of complex processing methods, affecting the performance of microfluidic systems, and high cost, and achieve high efficiency processing methods, increased bonding rate, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

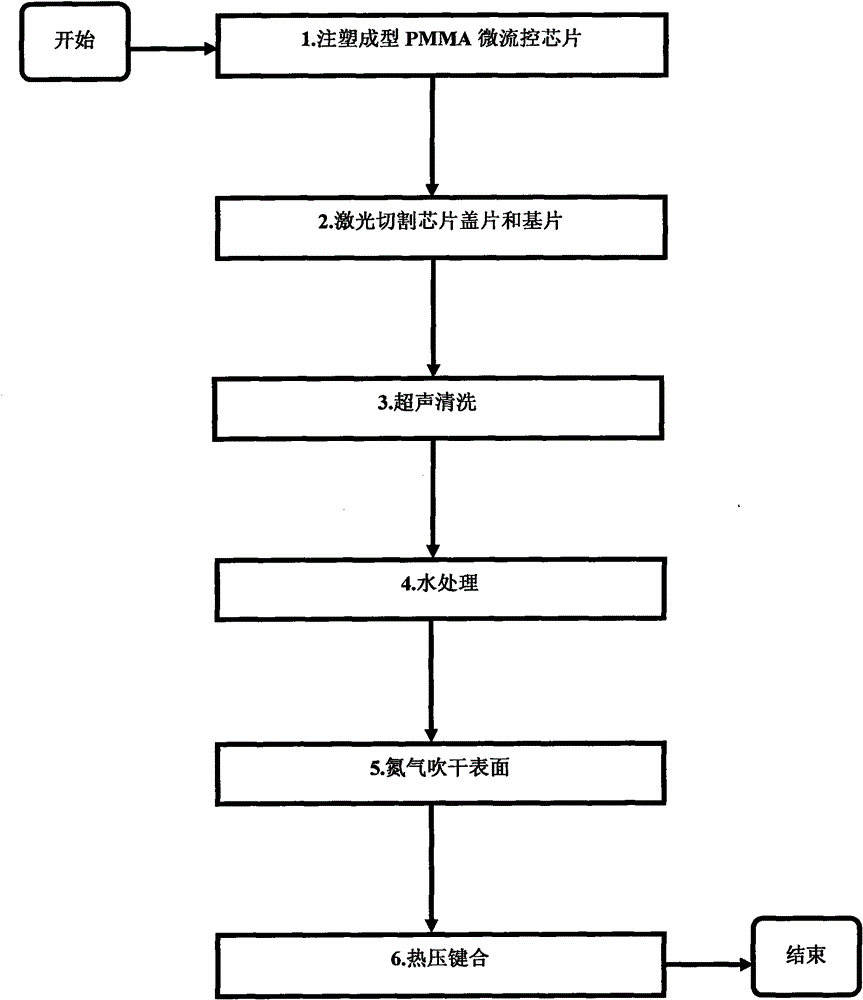

[0025] Example: A microfluidic chip with a size of 78×28mm is fabricated by using water treatment method. Attached figure 1 The process of making the chip, the specific steps are as follows:

[0026] 1. Injection molding PMMA microfluidic chip:

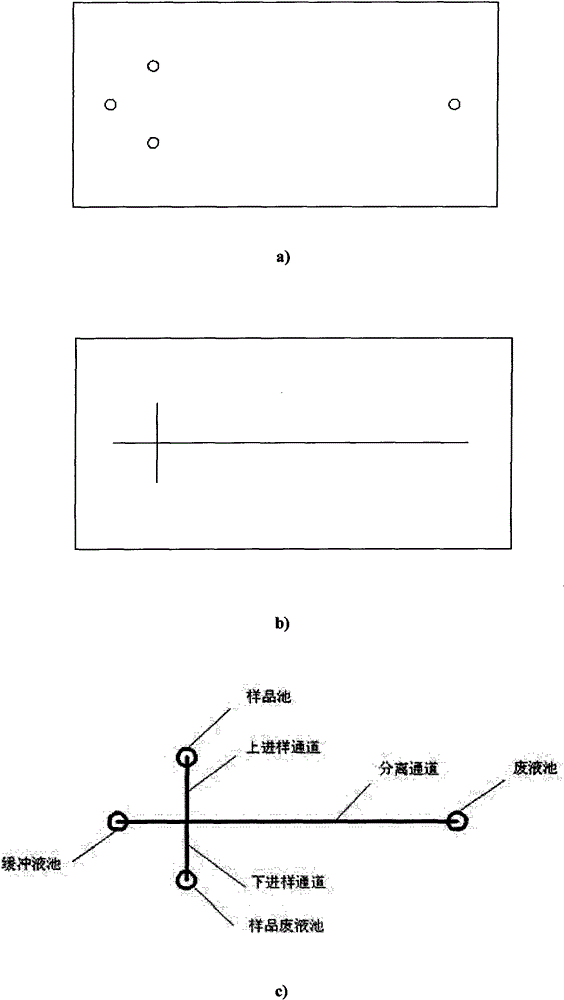

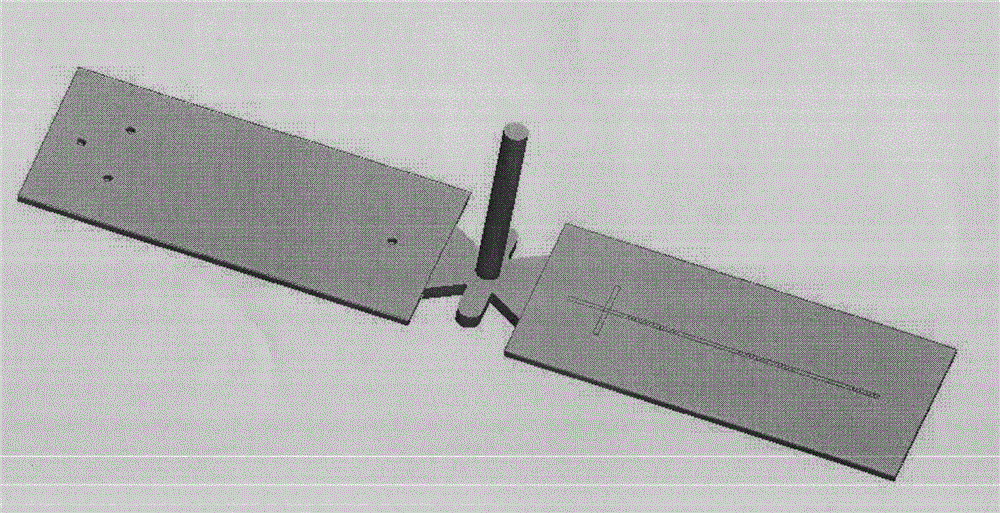

[0027] The cover and substrate of the PMMA microfluidic chip were injection-molded (equipment model: Zhende CJ80M3V injection molding machine), the mold temperature was 85°C, the melt temperature was 250°C, the filling time was 3s, the injection pressure was 140Mpa, and the holding time was 3s. The overall size of the chip obtained by injection molding is 82×40mm, in which there is a "cross-shaped" microchannel pattern on the cover sheet. The small hole of Φ2 is the chip reservoir, see attached figure 2 , 3 .

[0028] 2. Laser cutting chip cover and substrate:

[0029] Laser cut the chip cover and substrate (equipment model: Leishen CLS2000 laser engraving and cutting machine), the cutting current is 3.5mA, the knife passes 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com