Treatment method of nickel-containing eluvial ores

A treatment method and technology of nickel residue, which is applied in the field of metallurgy, can solve the problems of increased loss of valuable components, poor slag properties, and increased system slag volume, so as to improve the effective use of resources, reduce secondary pollution, and improve slag properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

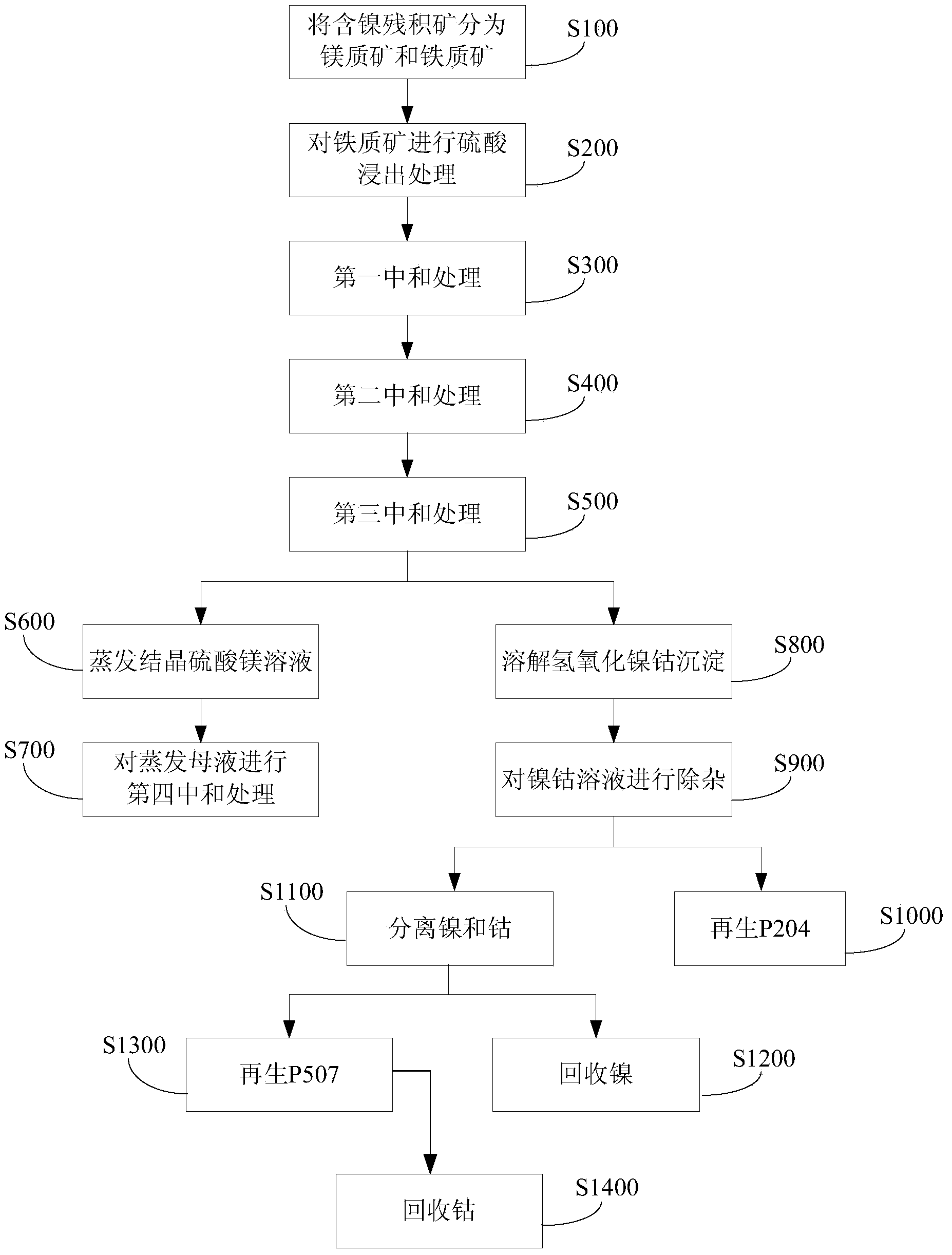

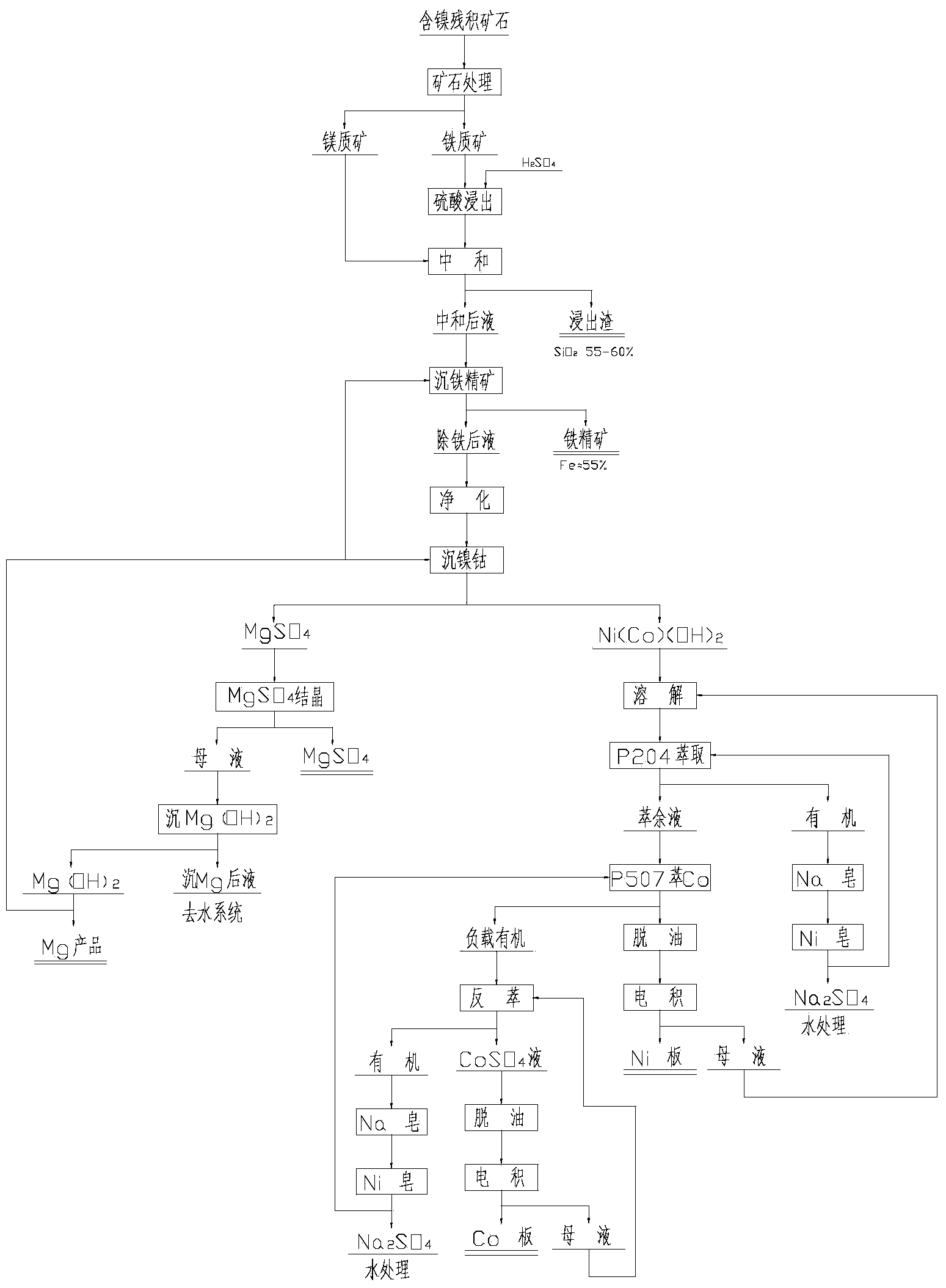

[0097] refer to figure 2 , 1) First divide the nickel-containing residual ore to be treated into magnesian ore and iron ore; 2) Then, at a temperature of 85-98 degrees Celsius, use sulfuric acid to leach the iron ore in order to obtain ferric sulfate The leaching solution, wherein the free acid content in the leaching solution containing iron sulfate is 40-45g / l; 3) Then at a temperature of 85-98 degrees Celsius, the leaching solution containing iron sulfate is subjected to a first neutralization treatment using magnesia ore, In order to reduce the content of free acid in the leaching solution to 5g / l, filter and wash to obtain the neutralized liquid and the leaching residue containing silicon dioxide, which contains about 60% SiO2 in the leaching residue containing silicon dioxide and can be used in the building materials industry; 4 ) further use magnesium hydroxide to carry out the second neutralization treatment on the neutralized liquid obtained in the previous step, mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com