Solidifying agent of repairing high-concentration multiple heavy metal polluted site and preparation and application methods thereof

An application method and curing agent technology, applied in the direction of chemical instruments and methods, restoration of contaminated soil, application, etc., can solve the problems of high cost, lack of reducibility, increase in soluble arsenic, etc., to achieve strong fixation ability, Good curing effect, good adsorption and reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

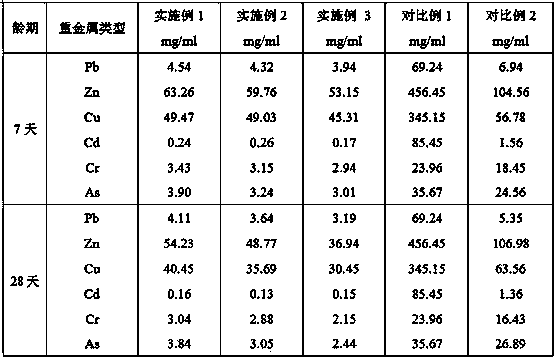

Examples

preparation example Construction

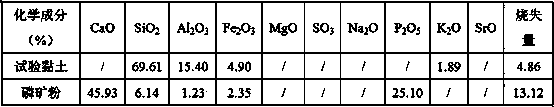

[0025] The above-mentioned modified phosphate rock powder is prepared by the following method: first, the phosphate rock is ground and passed through a 200 mesh sieve, and the P in the phosphate rock is 2 o 5 The mass percentage of the phosphate rock is 20-30%, and the phosphate rock powder is obtained. The phosphate rock powder, attapulgite and ferric chloride are uniformly mixed in a mass ratio of 5-4:3-2:1 to form Mixed material; then, mix the mixed material with acetic acid buffer solution with a molar concentration of 1mol / L at a mass ratio of 1:20~30, shake and stir for 10~15 hours at a temperature of 20~30°C, and let stand After 64-80 hours, the first gel-like precipitate is formed, which is dried and pulverized at a temperature of 80-100° C., and passed through a 200-mesh sieve to obtain modified phosphate rock powder.

[0026] The preparation method of the above-mentioned curing agent for repairing high-concentration multiple metal-contaminated sites comprises the f...

Embodiment 1

[0047] According to the preparation method of curing agent of the present invention, adopt above-mentioned test material to prepare curing agent, concrete process is as follows:

[0048] Step 1) Preparation of modified phosphate rock powder: First, grind the phosphate rock through a 200-mesh sieve to obtain phosphate rock powder. The mass ratio of the phosphate rock powder, attapulgite and ferric chloride is 4:2:1 Mix evenly to form a mixed material; then, mix the mixed material with the acetate buffer solution with a molar concentration of 1mol / L in a mass ratio of 1:30, shake and stir for 15 hours at a temperature of 30°C, and let it stand After 80 hours, the first gel-like precipitate was formed, which was dried and pulverized at a temperature of 100° C., and passed through a 200-mesh sieve to obtain modified phosphate rock powder;

[0049] Step 2) Preparation of curing agent: Mix the modified phosphate rock powder prepared in step 1) and light-burned magnesium oxide evenly...

Embodiment 2

[0052] According to the preparation method of curing agent of the present invention, adopt above-mentioned test material to prepare curing agent, concrete process is as follows:

[0053] Step 1) Preparation of modified phosphate rock powder: First, grind the phosphate rock through a 200-mesh sieve to obtain phosphate rock powder. The mass ratio of the phosphate rock powder, attapulgite and ferric chloride is 5:3:1 Mix evenly to form a mixed material; then, mix the mixed material with the acetate buffer solution with a molar concentration of 1mol / L in a mass ratio of 1:20, shake and stir for 10 hours at a temperature of 20°C, and let it stand After 64 hours, the first gel-like precipitate was formed, which was dried and pulverized at a temperature of 80° C., and passed through a 200-mesh sieve to obtain modified phosphate rock powder;

[0054] Step 2) Preparation of curing agent: Mix the modified phosphate rock powder prepared in step 1) and light-burned magnesia evenly to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com