Application method for MIL-100(Fe) catalyst in NH3-SCR (Selective Catalytic Reduction) reaction

A technology of NH3-SCR and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., and can solve problems such as poor adsorption capacity, high porosity, and high working temperature. problem, to achieve good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

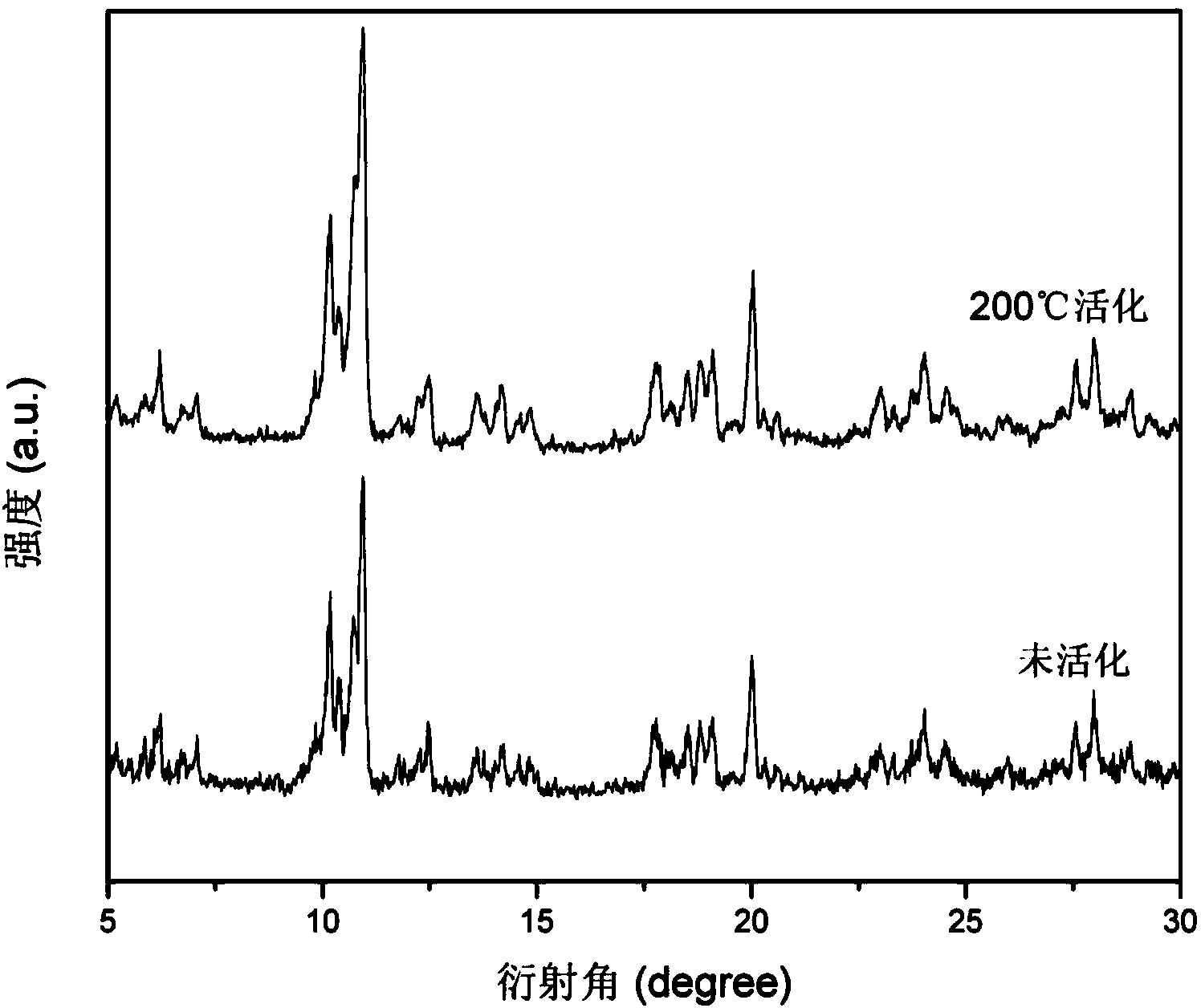

[0029] Synthesis and Purification of MIL-100(Fe) Catalyst by Hydrothermal Method

[0030] Weigh 277.5mgFe powder and 687.5mgH 3 BTC mixed into 25ml ultrapure water, and 200ul HF and 190ul HNO 3Add it into it, and then use a glass rod to continuously stir for about 5 minutes, then transfer the mixed solution to a 100ml reaction kettle with a polytetrafluoroethylene liner, and seal it. Then the reaction vessel was heated in an oven at 150 °C for 15 h. After the reaction was completed, the reactor was cooled to room temperature. Centrifuge and dry overnight in an oven at 80°C to obtain a light orange powdery solid. Purification of Fe-MOFs: First, mix the obtained light orange sample with ultrapure water (1.0g sample / 350ml ultrapure water) into a 500ml beaker, and stir in an oil bath at 80°C for 5h. It was centrifuged; then, the sample was mixed with fresh ethanol solution (1.0g sample / 200ml ethanol), and stirred in an oil bath at 60°C for 3h. Cool to room temperature, centri...

Embodiment 2

[0032] for NH 3 -The method of the MIL-100 (Fe) catalyst of SCR reaction, its step is as follows:

[0033] (1) Pretreatment of MIL-100(Fe) catalyst: take not less than 0.3g of MIL-100(Fe) catalyst, press it into tablets under the condition of 5-15Mpa, crush and sieve to obtain 20-40 mesh MIL- 0.2g of 100(Fe) catalyst particles, which is NH 3 - MIL-100(Fe) catalyst for SCR reaction;

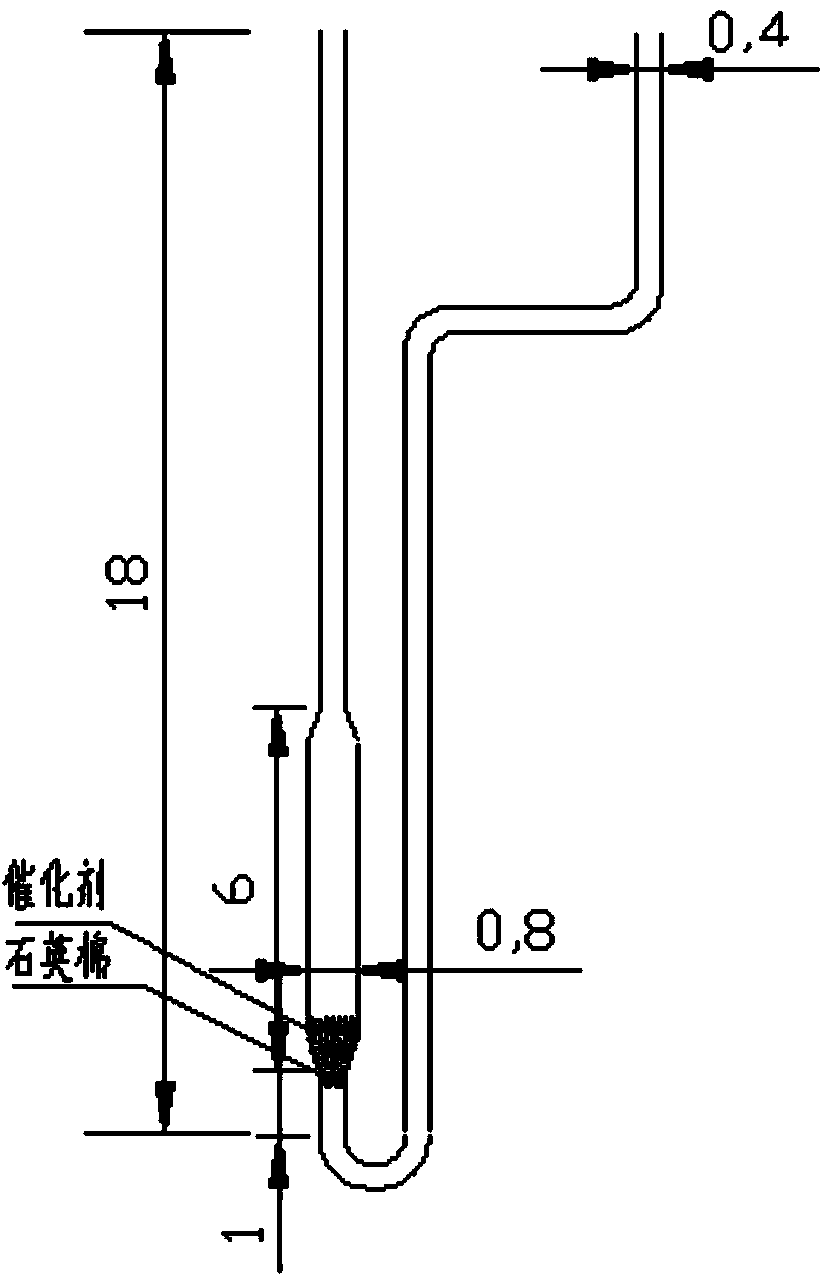

[0034] (2) NH 3 -SCR reaction: Place the MIL-100(Fe) catalyst obtained in step (1) on the quartz wool of the reaction tube equipped with quartz wool. The reaction tube is a U-shaped quartz tube with an inner diameter of 4mm, and there is a section of diameter on the left side Dilated to 8mm and 6cm in length. Fix the thermocouple on the quartz tube with copper wire. Close the resistance furnace and seal the nozzle. NO, NH 3 , O 2 and N 2 The valve of the gas is opened, and the gas is mixed and passed into the quartz reaction tube; the reaction temperature is 25°C; the mixed gas is NO, NH ...

Embodiment 3

[0036] for NH 3 -The method of the MIL-100 (Fe) catalyst of SCR reaction, its step is as follows:

[0037] (1) Pretreatment of Fe-MOFs catalyst: take not less than 0.3g of MIL-100(Fe) catalyst, press it into tablets under the condition of 5-15Mpa, crush it, and sieve it to obtain 20-40 mesh Fe-MOFs catalyst particles 0.2g, that is NH 3 - MIL-100(Fe) catalyst for SCR reaction;

[0038] (2) NH 3 -SCR reaction: Place the MIL-100(Fe) catalyst obtained in step (1) on the quartz wool of the reaction tube equipped with quartz wool. The reaction tube is a U quartz-shaped tube with an inner diameter of 4mm, and there is a section of diameter Dilated to 8mm and 6cm in length. Fix the thermocouple on the quartz tube with copper wire. Close the resistance furnace and seal the nozzle. NO, NH 3 , O 2 and N 2 The valve of the gas is opened, and the gas is mixed and passed into the quartz reaction tube; the reaction temperature is 220°C; the mixed gas is NO, NH 3 , O 2 , N 2 Mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com