Method for processing zinc concentrate with high content of indium and iron

A treatment method, zinc concentrate technology, applied in the field of smelting of non-ferrous metals, can solve the problems of high risk, impact on benefits, low recovery rate of indium smelting, etc., achieve the effect of reducing production costs, improving equipment efficiency, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

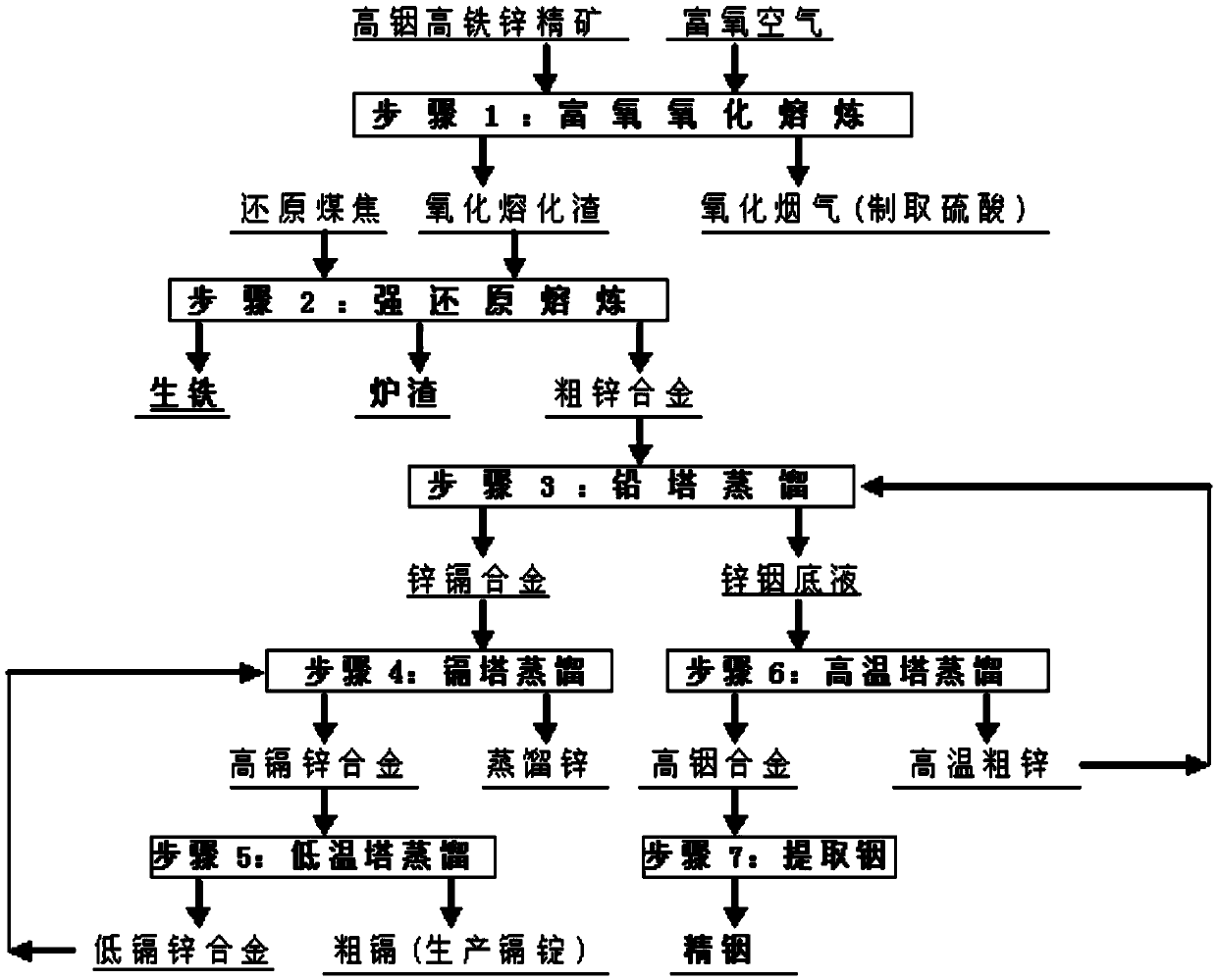

[0026] see figure 1 , a method for processing high-indium and high-iron-zinc concentrates, the steps are as follows:

[0027] (1) Oxygen-enriched oxidation smelting: Zinc concentrate containing 0.04% In, 14% Fe, 32% Zn, and 26% S by mass is continuously added to Ausmelt with an inner diameter of 5000mm at a rate of 20t / h Furnace, while at 13500Nm 3 / h speed into the oxygen-enriched air with an oxygen volume concentration of 54% and 4500Nm 3 / h speed into the sleeve air, at a temperature of 1200 ° C, oxygen-enriched oxidation melting, and the output of 17500Nm 3 / h oxidation flue gas and 17t / h molten slag, oxidation flue gas contains SO 2 20%, containing O 2 15%, using the traditional two-turn-two-absorption process to produce sulfuric acid;

[0028] (2) Strong reduction smelting: Molten slag is added to an Ausmelt furnace with an inner diameter of 5000mm with a lead rain condenser at a rate of 17t / h for strong reduction smelting, and the reduced coal is mixed in at a rati...

Embodiment 2

[0035] see figure 1 , a method for processing high-indium and high-iron-zinc concentrates, the steps are as follows:

[0036] (1) Oxygen-enriched oxidation smelting: Zinc concentrate containing 0.14% In, 20% Fe, 40% Zn, and 28% S in terms of mass is continuously fed into an Isa furnace with an inner diameter of 5000mm at a speed of 18t / h , while at 18000Nm 3 Spray oxygen-enriched air with an oxygen volume concentration of 48% at a speed of / h, and carry out oxygen-enriched oxidation melting at a temperature of 1250°C, and produce 17500Nm 3 / h oxidation flue gas and 15.6t / h molten slag, oxidation flue gas contains SO 2 21%, containing O 2 16%, using the traditional two-to-two-absorption process to produce sulfuric acid;

[0037] (2) Strong reduction smelting: The molten slag flows into four electric furnaces with a power of 5400kVA and an inner diameter of 5000mm with a lead rain condenser at a rate of 3.9t / (h.unit) for strong reduction smelting. The ratio of 28% by mass i...

Embodiment 3

[0044] see figure 1 , a method for processing high-indium and high-iron-zinc concentrates, the steps are as follows:

[0045] (1) Oxygen-enriched oxidation smelting: Zinc concentrate containing 0.24% In, 25% Fe, 50% Zn, and 20% S in terms of mass is continuously added to the side with an inner size of 4000mm×3000mm at a speed of 5t / h. Blowing furnace at the same time with 4000Nm 3 Inject oxygen-enriched air with an oxygen volume concentration of 38% at a rate of / h, and carry out oxygen-enriched oxidation melting at a temperature of 1300°C, and produce 4300Nm 3 / h oxidation flue gas and 4.5t / h molten slag, oxidation flue gas contains SO 2 19%, containing O 2 13%, using the traditional two-turn-two-absorption process to produce sulfuric acid;

[0046] (2) Strong reduction smelting: The molten slag flows into the Isa furnace with a lead rain condenser with an inner diameter of 3400mm at a speed of 4.5t / h for strong reduction smelting. , that is, 1.35t / h, melting temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com