Method for preparing ferro-silicon-boron amorphous magnetic conductive adhesive

An iron-silicon-boron and amorphous technology is applied in the field of polymer glue preparation, which can solve the problems of magnetic flux, small calorific value, magnetic conductive glue, etc. in the magnetic circuit of the iron core, and achieve the effect of improving the magnetic flux, small calorific value, and excellent magnetic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The method for preparing the iron-silicon-boron amorphous magnetic-permeable adhesive provided in this embodiment includes the following steps:

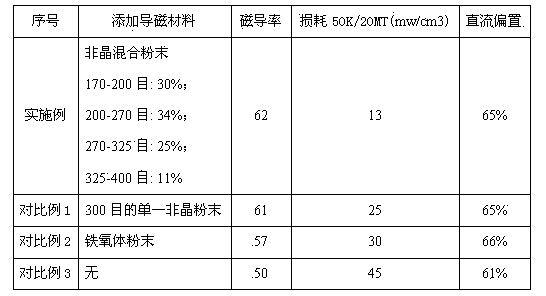

[0032] Step 1, crushing the amorphous strip into powder by mechanical crushing method, sieving out different particle sizes, and mixing the powders according to the powder particle size ratio range and weight content in Table 1;

[0033] Step 2: heat-treat the mixed powder in a nitrogen protective atmosphere at 450°C for 50 minutes, add acetone solvent, stir and mix evenly, and then pour it into a high-pressure reactor;

[0034] Step 3, adding quality to the autoclave is the adhesive matrix material epoxy resin E-20 of 7 times of the amorphous mixed powder in step 1 and 2% mineralizer concentrated hydrochloric acid (concentration is 35%), and supplement Add an appropriate amount of acetone to make the material in the reactor account for 75% of the volume. Under the condition of stirring, heat the reactor to 70°C and keep it wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com