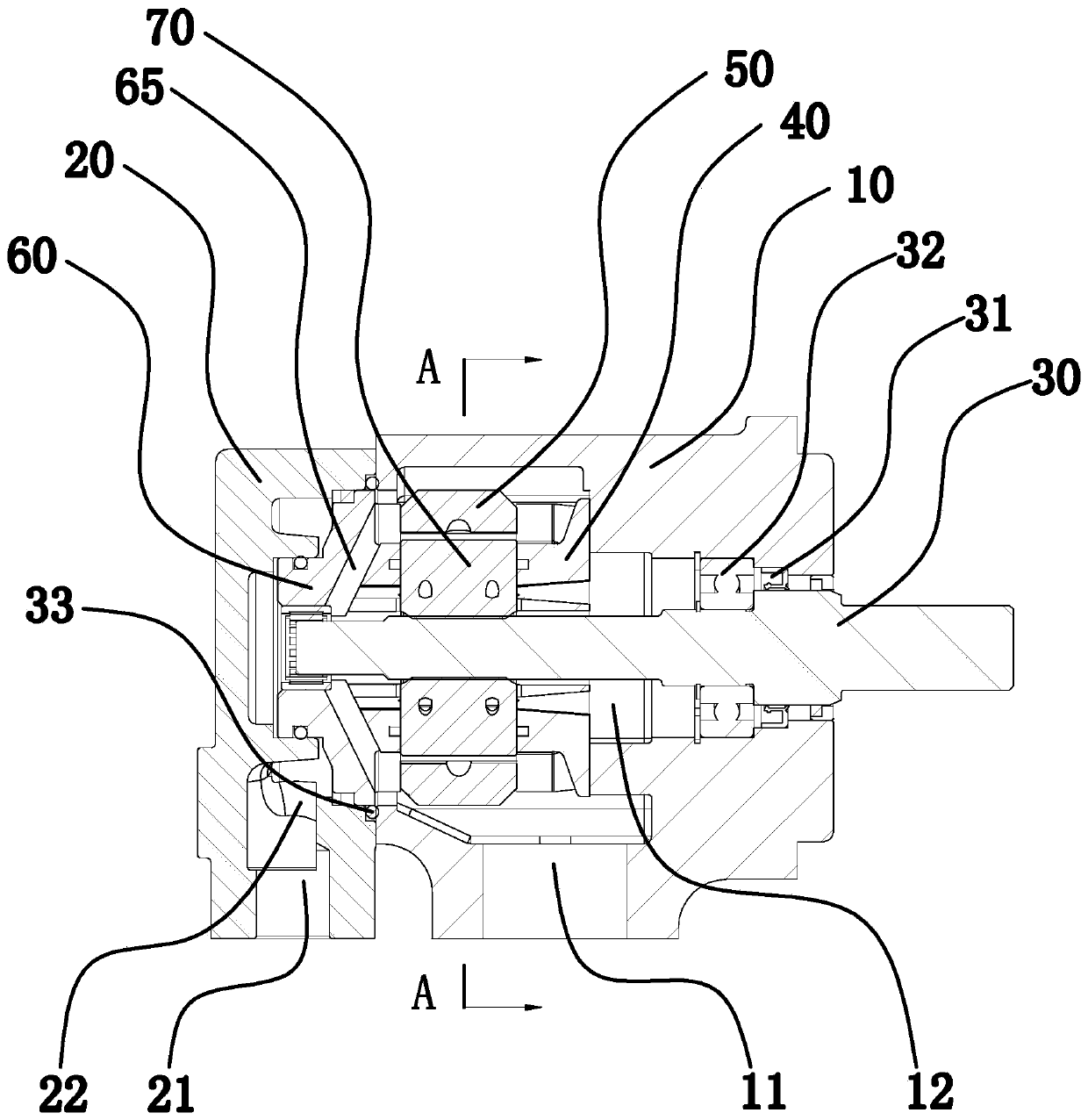

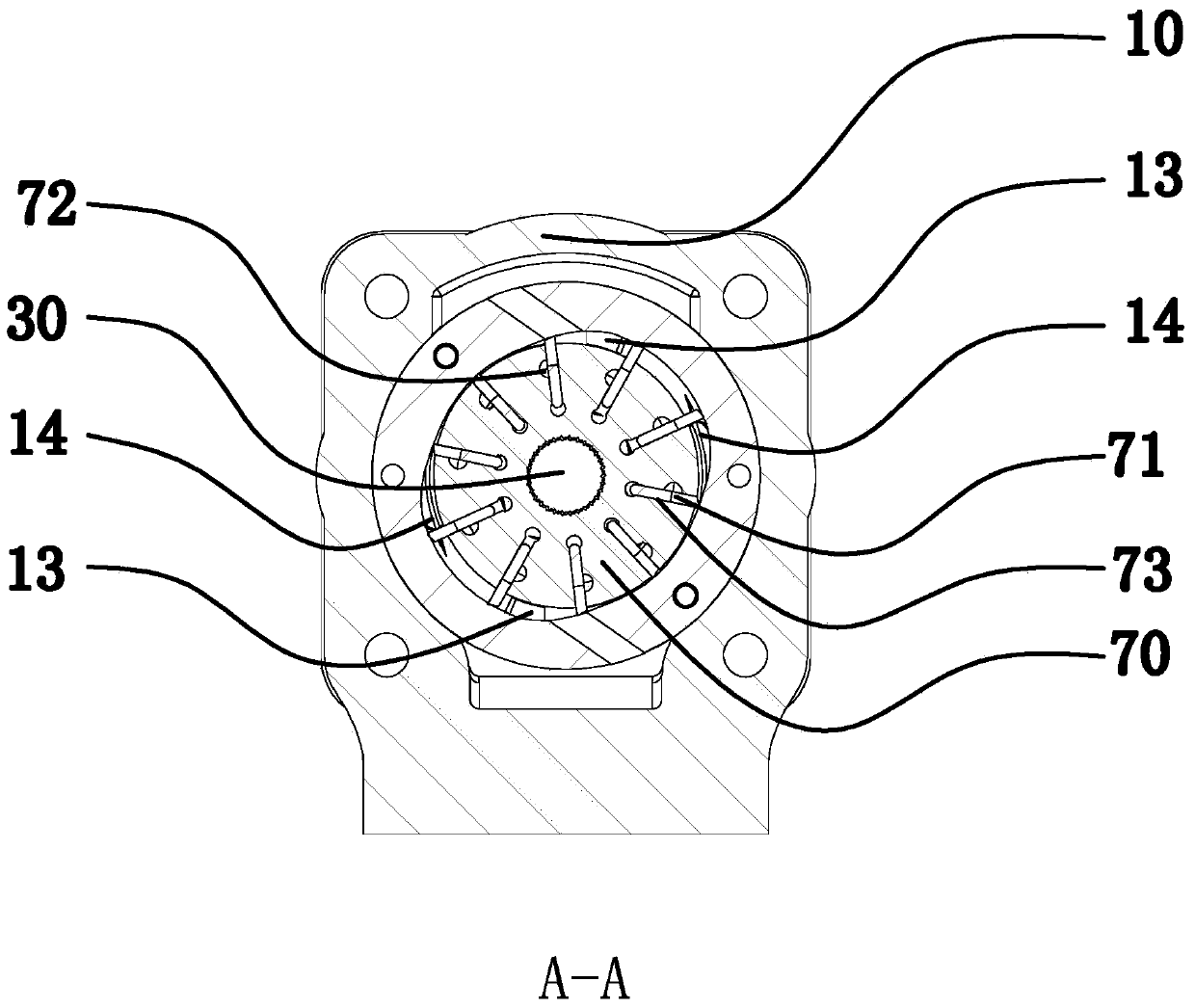

Double-acting impeller pump

An impeller pump, double-acting technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of large backflow, high noise of vane pumps, large pump vibration, etc., to achieve reduced requirements, good wear resistance, The effect of reducing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Carbon steel is selected as the raw material, sawed according to the shape and specification of the blade in the double-acting impeller pump, and formed into a blade blank after forging; wherein, the composition and mass percentage of the carbon steel are: C: 0.22%, Si: 0.17%, Mn: 0.50%, Cr: 0.25%, Ni: 0.30%, Cu: 0.25%, and the balance is Fe and unavoidable impurities.

[0068] The above-mentioned blade blanks were normalized at 860°C for 50 minutes. After normalizing, they were water-cooled at 70°C until the blade temperature was 300°C, and then air-cooled.

[0069] Rough machining and semi-finishing of the above-mentioned blade blank after normalizing treatment, and then carburizing and quenching, and finishing after carburizing and quenching treatment, to obtain a semi-finished blade; wherein, the carburizing temperature is 920°C, the carburizing time is 45min, the infiltration agent is methane gas infiltration agent, the quenching temperature is 820°C, and the quenc...

Embodiment 2

[0072] Select carbon steel as the raw material, saw and cut according to the shape and specification of the blade in the double-acting impeller pump, and form the blade blank after forging; wherein, the composition and mass percentage of the carbon steel are: C: 0.25%, Si: 0.27%, Mn: 0.60%, Cr: 0.20%, Ni: 0.25%, Cu: 0.20%, and the balance is Fe and unavoidable impurities.

[0073] Normalize the above-made blade blanks at 895°C for 60 minutes. After normalizing, water-cool at 75°C until the blade temperature is 350°C, and then air-cool.

[0074] Rough machining and semi-finishing of the above-mentioned blade blank after normalizing treatment, and then carburizing and quenching, and finishing after carburizing and quenching treatment, to obtain a semi-finished blade; wherein, the carburizing temperature is 930°C, the carburizing time is 60min, the infiltration agent is kerosene liquid infiltration agent, the quenching temperature is 850°C, and the quenching time is 30min.

[00...

Embodiment 3

[0077] Carbon steel is selected as the raw material, sawed according to the shape and specification of the blade in the double-acting impeller pump, and formed into a blade blank after forging; wherein, the composition and mass percentage of the carbon steel are: C: 0.29%, Si: 0.37%, Mn: 0.80%, Cr: 0.22%, Ni: 0.27%, Cu: 0.28%, and the balance is Fe and unavoidable impurities.

[0078] Normalize the above-made blade blanks at 930°C for 80 minutes. After normalizing, water-cool at 80°C until the blade temperature is 400°C, and then air-cool.

[0079] Rough machining and semi-finishing of the above-mentioned blade blank after normalizing treatment, and then carburizing and quenching, and finishing after carburizing and quenching treatment, to obtain a semi-finished blade; wherein, the carburizing temperature is 940°C, the carburizing time is 90min, the infiltration agent is alcohol liquid infiltration agent, the quenching temperature is 870°C, and the quenching time is 45min.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com