Linear cutting fluid for neodymium-iron-boron permanent magnet material

A permanent magnet material and wire cutting technology, applied in the petroleum industry, lubricating composition, etc., can solve the problem of small discharge gap, unfavorable cooling and chip removal of electrical machining process, no consideration of the conductivity of cutting fluid, and the lack of conductivity of electrolyte substances and other problems, to achieve the effect of excellent cleaning, improved chip removal performance, good electrical conductivity and lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]A wire cutting fluid for NdFeB permanent magnet materials, the wire cutting fluid is composed of the following components by weight percentage, the specific embodiment is: 3% of oleic acid and 3% of sebacic acid are added to the reaction kettle, and the temperature is raised to 60°C, add 2% monoethanolamine, 4% diethanolamine, and 6% triethanolamine under stirring, continue to heat up to 150°C for 2 hours, then cool down to 80°C and add 3% amino borophosphonate, nonyl Phenol polyoxyethylene ether (OP-10) 6%, borate 3%, sodium molybdate 0.5%, sodium phosphate 5%, diethylamine tetraacetic acid 0.3%, emulsified silicone oil 0.5% and water 63.7%, continue to stir for 2h That is the finished product.

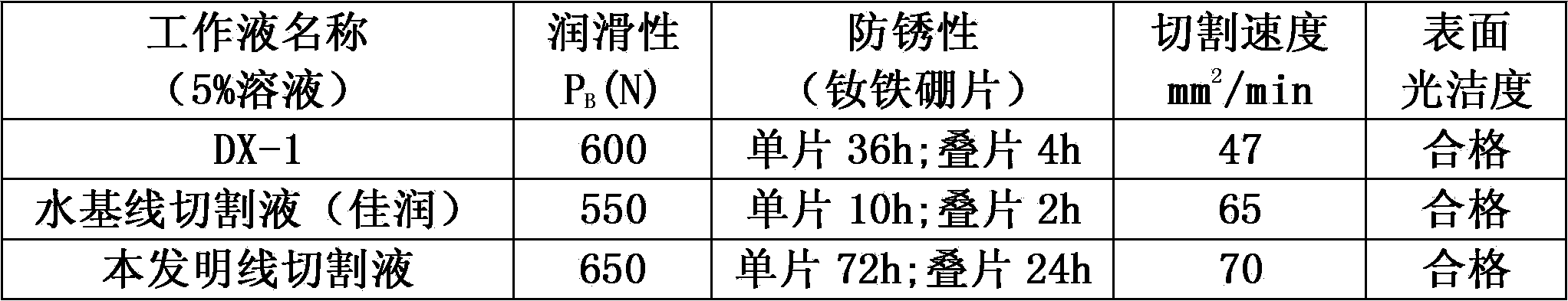

[0044] Examples 2-5 are calculated by weight percentage. The components and dosage of each raw material are shown in Table 2. The preparation method and operation steps are the same as in Example 1.

[0045] Table 2 The raw material components and dosage of Examples 2 to 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com