Iron-like concentrate and its preparation method

An iron concentrate and iron technology, applied in the field of metallurgy, can solve problems such as polluting the environment and occupying land, and achieve the effects of low sulfur content, increase enterprise income, and reduce potential pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

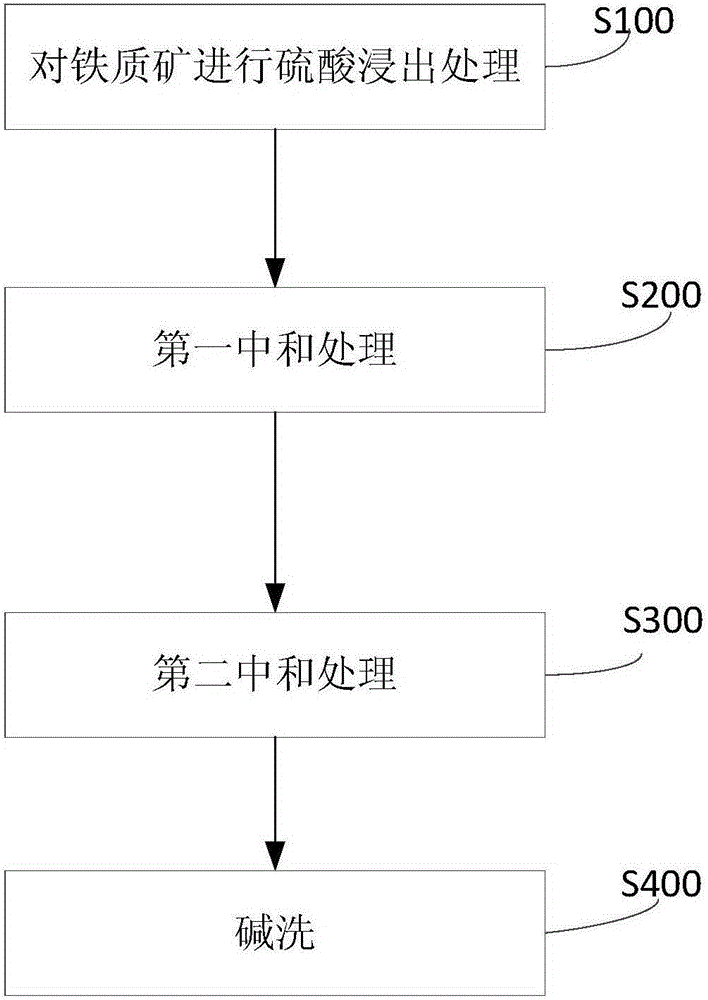

Method used

Image

Examples

Embodiment 1

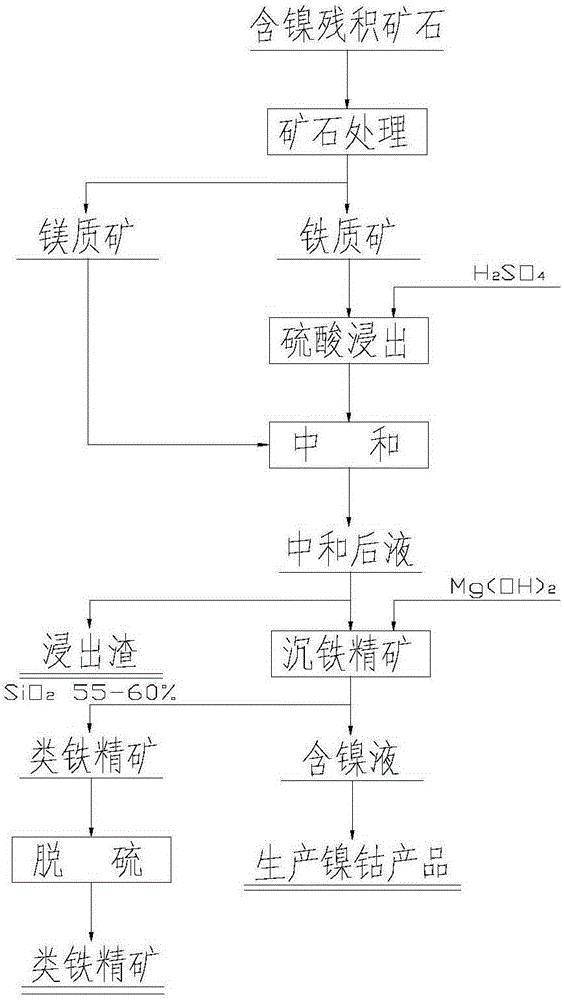

[0065] Embodiment 1 Discontinuous test of iron precipitation from nickel-containing residual ore leaching solution

[0066] Use a 3L glass beaker, electric heating to maintain the temperature in the leach solution of nickel-containing residual ore at 95-105°C, and a mechanical stirring speed of 250rpm. Use magnesium hydroxide slurry to adjust the pH value of the leach solution to 1.3. During the reaction, use a pH meter to monitor in real time. After 6 hours, 85-95% Fe in the leaching solution precipitated, of which the nickel content was 0.15%, and the iron slag contained about 54%.

Embodiment 2

[0067] Example 2 Continuous test of iron precipitation from nickel-containing residual ore leaching solution

[0068] Use four 3L beakers in series to form a reaction vessel, mechanically stir, and electric heating to maintain the reaction temperature at 100-105°C, install a pH meter on the second and fourth beakers to monitor the acidity of the leachate, and maintain the pH value of the leachate at 1.3-2.0, one 5L clarifier device.

[0069] Add nickel-containing residual ore leaching solution (700ml / h) and magnesium hydroxide slurry to the first reactor at the same time by quantitative pump, the clarifier supernatant contains Fe2-3g / l, the bottom flow contains 55% iron and 3.0-2.5% sulfur, and filter After alkali washing, hematite-like ore with a sulfur content of 1.0-1.5% is produced.

Embodiment 3

[0071] At normal pressure and at a temperature of 95 to 100 degrees Celsius, sulfuric acid is used to leach iron ore to obtain a leaching solution containing ferric sulfate (the iron content in the leaching slurry is about 40g / l (Fe 2+ 2 63%) and filtrate. Under the conditions of normal pressure, temperature 95-100°C and mechanical stirring speed of 250rpm, use magnesia ore (containing Mg18-20%) to neutralize Fe in the obtained filtrate 3+ For the acid generated by the hydrolysis reaction, the concentration of free acid in the filtration solution is reduced from 40-45g / l to 4.5-5g / l. At the same time, valuable components such as nickel and cobalt in the magnesia ore are dissolved by acid, and when the pH value drops to 1.5-2.0, iron removal from the leaching solution can be realized. Filter the mixed solution neutralized with magnesia ore, and add magnesium hydroxide slurry to the filtrate to neutralize the sulfuric acid precipitated during iron precipitation. During the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com