Method for improving ablation resistance of boron-containing phenolic resin-based composite material

A boron phenolic resin and composite material technology, which is applied in the field of high temperature resistant heat protection materials, can solve the problems of easy oxidation and erosion of boron phenolic resin-based composite materials, and achieves improved residual strength and ablation resistance, high mechanical strength and high mechanical strength. Effect of dimensional stability and high thermal residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

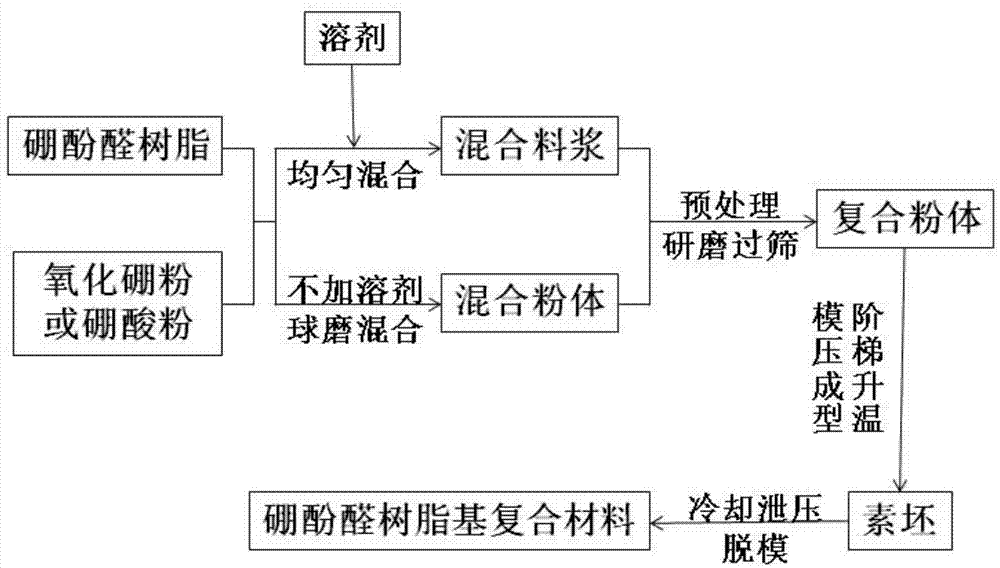

[0027] The invention provides a preparation method for improving the ablation resistance of a boron phenolic resin-based composite material, specifically: crushing and sieving the boron phenolic resin, and uniformly mixing the boron phenolic resin with boron oxide, boric acid and other powders by a solid phase method or a liquid phase method, The mass ratio of the two is 1:1 to 9:1; the solid phase method uses ball milling for 12 to 36 hours, and the liquid phase method uses an organic solvent to dissolve boron phenolic resin, and then stirs and mixes with a magnetic stirrer for 1 to 5 hours; The mixed powder or slurry is pretreated, and the pretreatment conditions are: treatment at 100-150°C for 1-10 hours; the pretreatment material is ground and sieved to obtain a composite powder of boron phenolic resin and boron oxide or boric acid, and then The composite powder is molded by a stepped temperature-rising molding process. The molding process is: hot pressing at 150-200°C unde...

Embodiment 1

[0031] (1) Mixing: crush the boron phenolic resin block into powder and pass through a 200-mesh sieve, then mix it with boron oxide powder with a particle size of less than 200 μm at a mass ratio of 9:1, and ball mill at a speed of 100 rpm for 36 hours ;

[0032] (2) Pretreatment: Treat the mixed powder at 100°C for 10 hours, grind it through a 200-mesh sieve, and obtain a composite powder of boron phenolic resin and boron oxide;

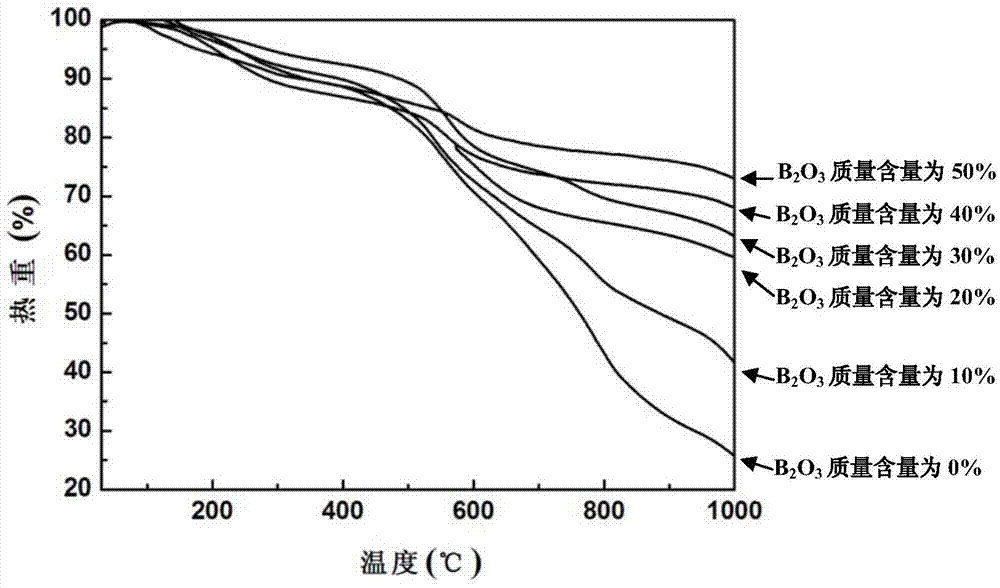

[0033] (3) Stair heating molding: the composite powder obtained by grinding and sieving after pretreatment is kept at 150°C for 3 hours under an axial pressure of 2 MPa, then heated to 180°C for 1 hour, and finally heated to 200°C for 1 hour; finally The boron-phenol-formaldehyde resin-based composite material is obtained by releasing the pressure and demolding with the furnace cooling. The obtained sample was heat-treated at 600°C for 2 hours in an air atmosphere. The thermal residual rate of the sample was 65%, the residual strength was 2.1 MPa, ...

Embodiment 2

[0035] (1) Mixing: crush the boron phenolic resin block into powder and pass through a 200-mesh sieve, then mix it with boron oxide powder with a particle size of less than 200 μm at a mass ratio of 4:1, and ball mill for 30 hours at a speed of 300 rpm ;

[0036] (2) Pretreatment: Treat the mixed powder at 110°C for 9 hours, and grind it through a 200-mesh sieve to obtain a composite powder of boron phenolic resin and boron oxide;

[0037] (3) Stair heating molding: the composite powder obtained by grinding and sieving after pretreatment is kept at 150°C for 2 hours under an axial pressure of 4 MPa, then heated to 180°C for 2 hours, and finally heated to 200°C for 1 hour; finally The boron-phenol-formaldehyde resin-based composite material is obtained by releasing the pressure and demolding with the furnace cooling. The obtained sample was heat-treated at 600°C for 2 hours in an air atmosphere. The thermal residual rate of the sample was 70%, the residual strength was 2.2 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass ablation rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com