Method for hydrophobically modifying surface of polymer

A hydrophobic modification and polymer technology, which is applied in the field of surface modification of polymer materials, can solve problems such as harsh preparation conditions, poor comprehensive performance, and complicated preparation process, and achieve no special equipment, easy large-scale implementation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

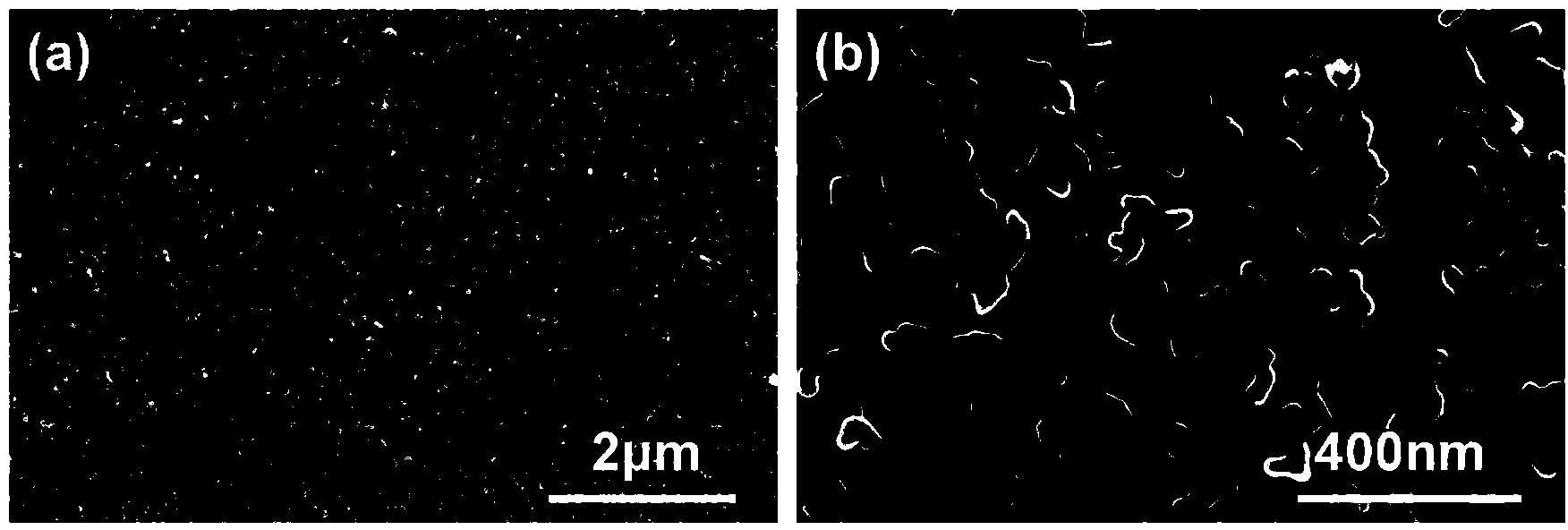

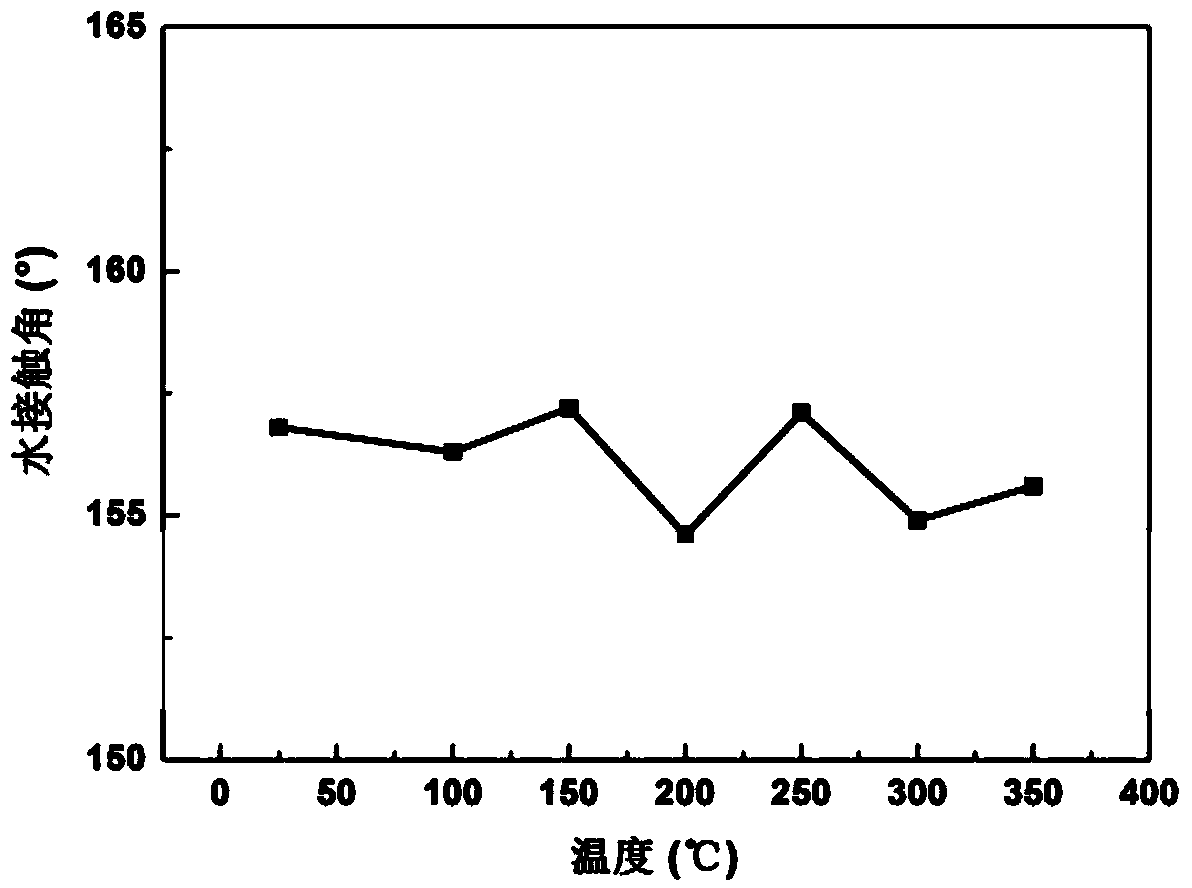

[0019] 1. Wash and dry the polyimide film first, then oxidize and etch the surface of the polyimide film by ultraviolet light oxidation method, use low-pressure quartz mercury lamps of 185nm and 254nm, control the power at 70W, and the intensity of ultraviolet light 10mW / cm 2 , wherein the light intensity ratio of 185nm and 254nm wavelengths is 10:90, and the thin film is taken out after oxidation etching for 72h, and obtained as figure 1 The micro-nano structure morphology shown includes micro-nano-scale ridge-like protrusions, channels, and island-like structures formed by nano-protrusion clusters. The surface water contact angle is less than 10°, showing a super-hydrophilic state;

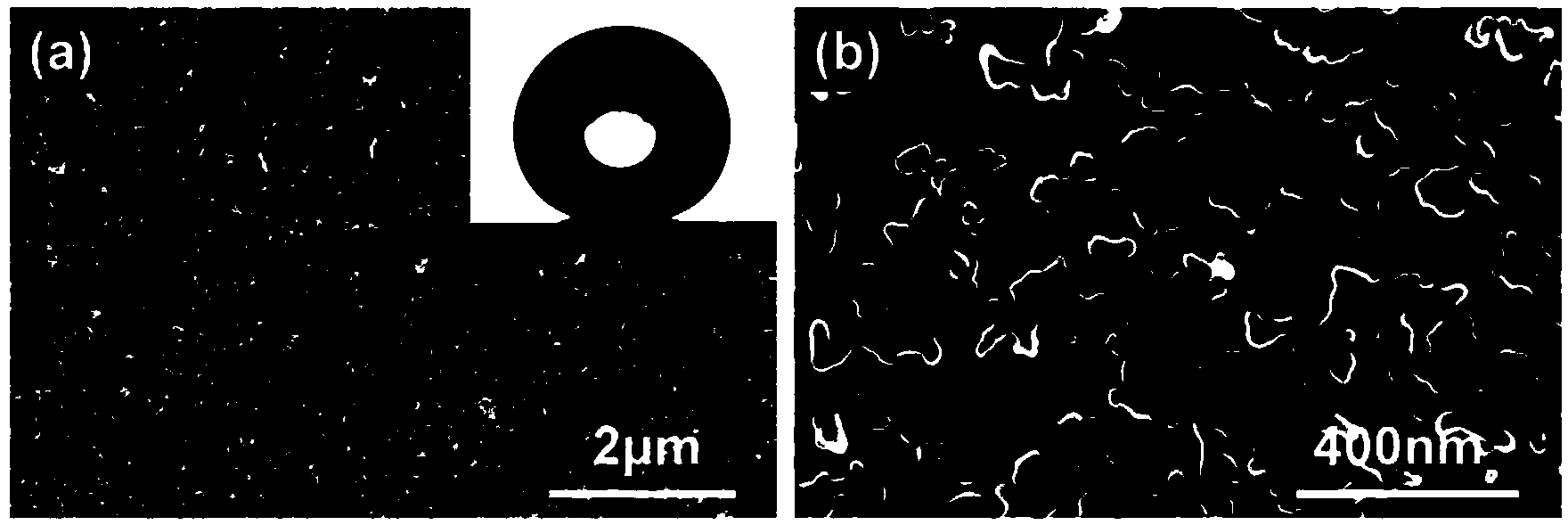

[0020] 2. Take 10 μL of 1H, 1H, 2H, 2H-perfluoroheptadecanetrimethyloxysilane and place it on the bottom of the polytetrafluoroethylene tank, and fix the polyimide film vertically in the polytetrafluoroethylene tank, and then After sealing with an autoclave, place it in an oven at 120°C to make...

Embodiment 2

[0023] 1. Wash and dry the polyimide film first, then oxidize and etch the surface of the polyimide film by ultraviolet light oxidation method, use low-pressure quartz mercury lamps of 185nm and 254nm, control the power to 40W, and the intensity of ultraviolet light 7mW / cm 2 , wherein the light intensity ratio of 185nm and 254nm wavelengths is 5:95, and the thin film is oxidized and etched for 96 hours and taken out;

[0024] 2. Put the polyimide film after ultraviolet light oxidation treatment in the p-xylene solution of 50mmol / L 1H, 1H, 2H, 2H-perfluoroheptadecanetrimethyloxysilane, and place it at 100°C Soak it in an oven for 3 hours, so that the surface after ultraviolet light oxidation treatment can fully react with 1H, 1H, 2H, 2H-perfluoroheptadecanetrimethyloxysilane; take it out after 2 hours of reaction, heat to 150 ° C, stir to make The unreacted 1H,1H,2H,2H-perfluoroheptadecanetrimethyloxysilane molecules volatilized (about 2h); naturally cooled to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com