Preparation method for amino silicone modified urushiol light-cured film

A technology of amino silicone and silicone, applied in the direction of coating, etc., can solve the problems of increased energy consumption, long time consumption, and high cost, and achieve the effects of excellent chemical resistance, low price, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 5.0 g of urushiol and 7.8 g of xylene into a three-necked flask, mix them in advance to form a mixed solution, raise the temperature to 138° C., and remove water at a constant temperature for 30 minutes.

[0034] After cooling the mixture to 80°C, add 6.7 g of 3-aminopropyltriethoxysilane (KH550), then raise the temperature to 90°C, and react for 3 hours to obtain 3-aminopropyltriethoxysilane modified paint Phenol prepolymer mixture.

[0035] Coat the 3-aminopropyltriethoxysilane-modified urushiol prepolymer mixture on a clean glass sheet and irradiate it under ultraviolet light for 30 seconds to obtain 3-aminopropyltriethoxysilane-modified Urushiol light-cured film.

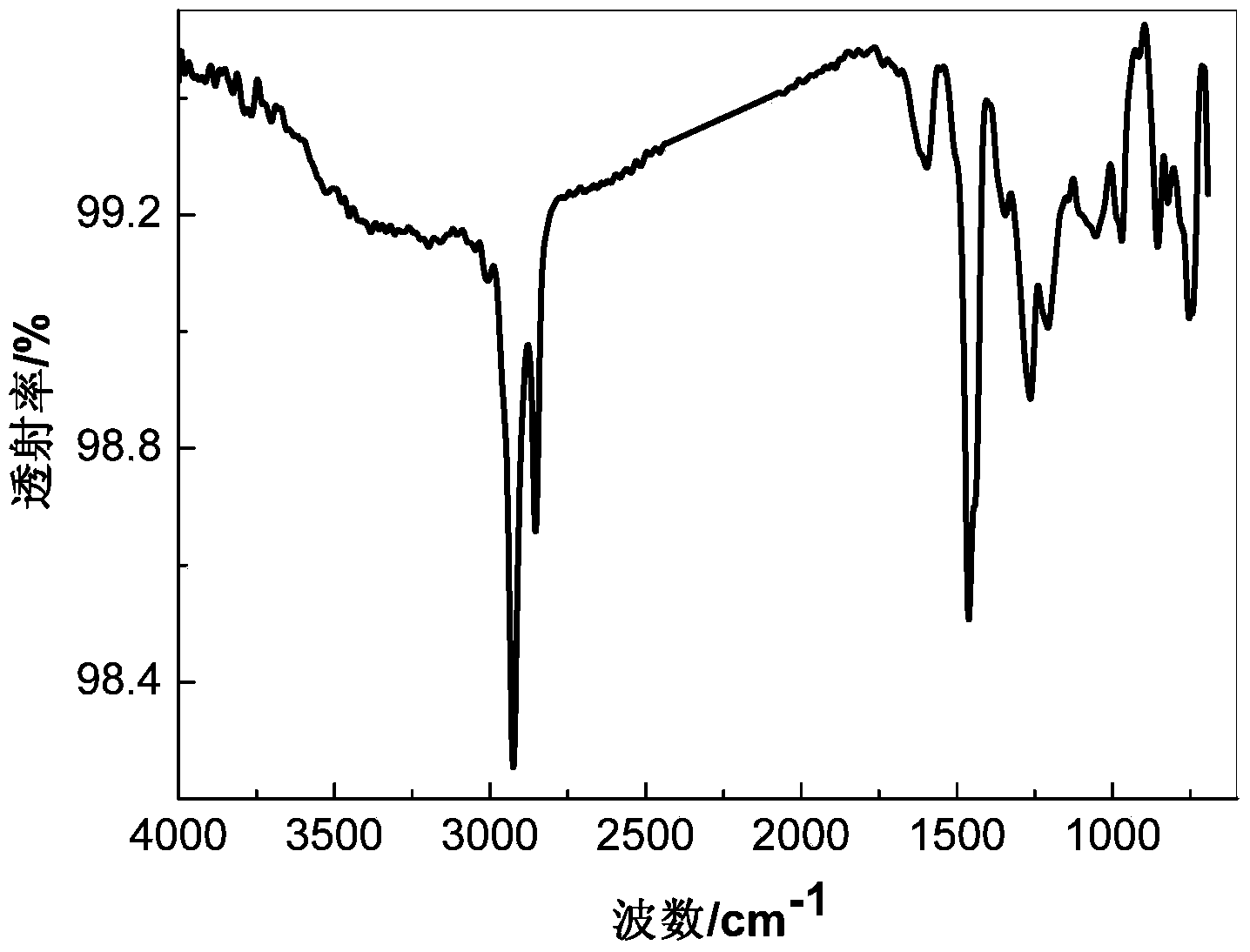

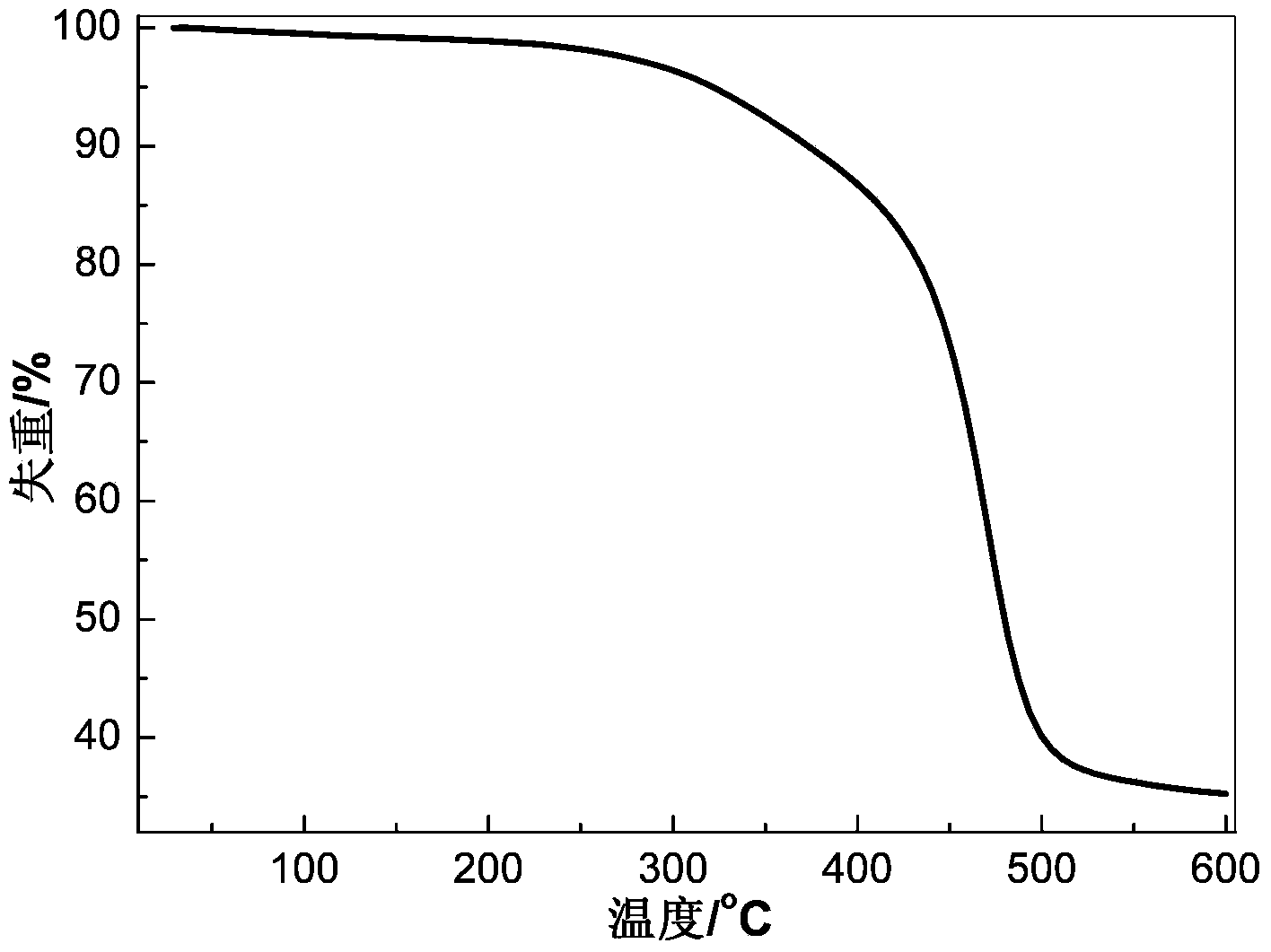

[0036] The prepared 3-aminopropyltriethoxysilane modified urushiol light-cured film was analyzed by infrared spectrogram, and the results are shown in the attached figure 1 Shown; Carry out thermal gravimetric spectrum analysis, its result is as attached figure 2 shown.

[0037] The performance t...

Embodiment 2

[0045] Add 6.7 grams of urushiol and 7.8 grams of xylene into a three-necked flask, mix them in advance to form a mixed solution, raise the temperature to 138° C., and remove water at a constant temperature for 30 minutes.

[0046] After cooling the mixed solution to 80°C, add 2.5 g of N-silylpropyl-N-formyl p-methylaniline and 2.0 g of 3-aminopropyltrimethoxysilane, then raise the temperature to 100°C, and react for 2 hours to obtain N-silylpropyl-N-formyl p-methylaniline-3-aminopropyltrimethoxysilane modified urushiol prepolymer mixture.

[0047] Coat the N-silylpropyl-N-formyl p-methylaniline-3-aminopropyltrimethoxysilane modified urushiol prepolymer mixture on the tinplate polished by sandpaper, and irradiate it under ultraviolet light After 60 seconds, an N-silylpropyl-N-formyl-p-methylaniline-3-aminopropyltrimethoxysilane-modified urushiol light-cured film was obtained.

[0048] The performance test results of the N-silylpropyl-N-formyl p-methylaniline-3-aminopropyltrim...

Embodiment 3

[0056] Add 8.0 g of urushiol and 7.8 g of xylene into a three-necked flask, mix them in advance to form a mixed solution, raise the temperature to 138° C., and remove water at constant temperature for 30 minutes.

[0057] After cooling the mixed solution to 80°C, add 3.6 g of bis(dimethylamino)methylvinylsilane, then raise the temperature to 110°C, and react for 1.5 hours to obtain bis(dimethylamino)methylvinylsilane modified urushiol prepolymer mixture.

[0058] Bis(dimethylamino)methylvinylsilane modified urushiol prepolymer mixture is coated on a clean glass sheet, and after 90 seconds of irradiation under ultraviolet light, bis(dimethylamino)methylvinyl Silane-modified urushiol light-cured film.

[0059] The performance test results of the bis(dimethylamino)methylvinylsilane-modified urushiol light-cured film prepared in this embodiment are as follows:

[0060] Pencil hardness: 6H

[0061] Adhesion: Level 1

[0062] Flexibility: 0.5 mm

[0063] Impact resistance: 50cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com