Fine-particle-proof mask with chitosan and nano-zinc oxide and manufacturing method of fine-particle-proof mask

A technology of nano-zinc oxide and fine particles, which is applied in the field of sanitary products preparation, can solve the problems of lack of protection against fine particles, difficulty in breathing, poor air permeability, etc., and achieve good market application prospects, high safety, and good air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

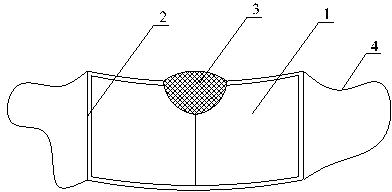

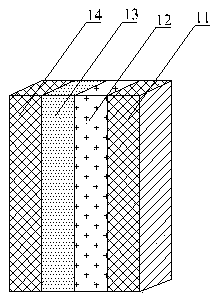

[0031] The anti-fine particle respirator containing chitosan and nano-zinc oxide of the present invention comprises cover body 1 and ear band 4 (left ear band and right ear band), and its overall structure schematic diagram is as follows figure 1 As shown, the periphery of the cover is provided with a cover frame 2, such as figure 2 As shown, the cover body frame 2 is provided with 4 layers of fillers, which are sequentially from the outside to the inside: the first layer is a non-woven fabric layer, the second layer of activated carbon non-woven fabric layer, and the third layer contains chitosan and nano Zinc oxide absorbent cotton gauze functional layer, the fourth layer is a non-woven fabric layer; it can effectively block fine particles from entering the human body, prevent secondary pollution of bacteria entering the mask body, and have good air permeability.

[0032] The mask body is also provided with a nasal mask 3 that can effectively protect the nose at the corresp...

Embodiment 2

[0043] The preparation method of the anti-fine particle mask containing chitosan and nano-zinc oxide of the present invention comprises the following steps:

[0044] (1) take by weighing 2g crab shell chitosan and be dissolved in the acetic acid solution of 50ml 1%, prepare the chitosan solution that mass volume ratio is 4%;

[0045] (2) Weigh 59.5gZn(NO 3 ) 2 ·6H 2 Dissolve O in 100ml distilled water, stir well to make 2M zinc nitrate aqueous solution, slowly add 0.1M NaOH solution and keep stirring to get white precipitate of zinc hydroxide, extract and wash the precipitate, add ammonia water to it and keep stirring until just no precipitate particles can be seen , the solution is translucent, then add a small amount of distilled water and move to a closed container to mark for later use;

[0046] (3) Soak the absorbent cotton gauze in the chitosan solution described in step (1), transfer it after 12 hours and soak it in 0.1% sodium hydroxide solution for 2 hours, rinse w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com