Light fiber-reinforced thermoplastic plate used for high-performance passenger vehicle bottom protection plate and preparation technology thereof

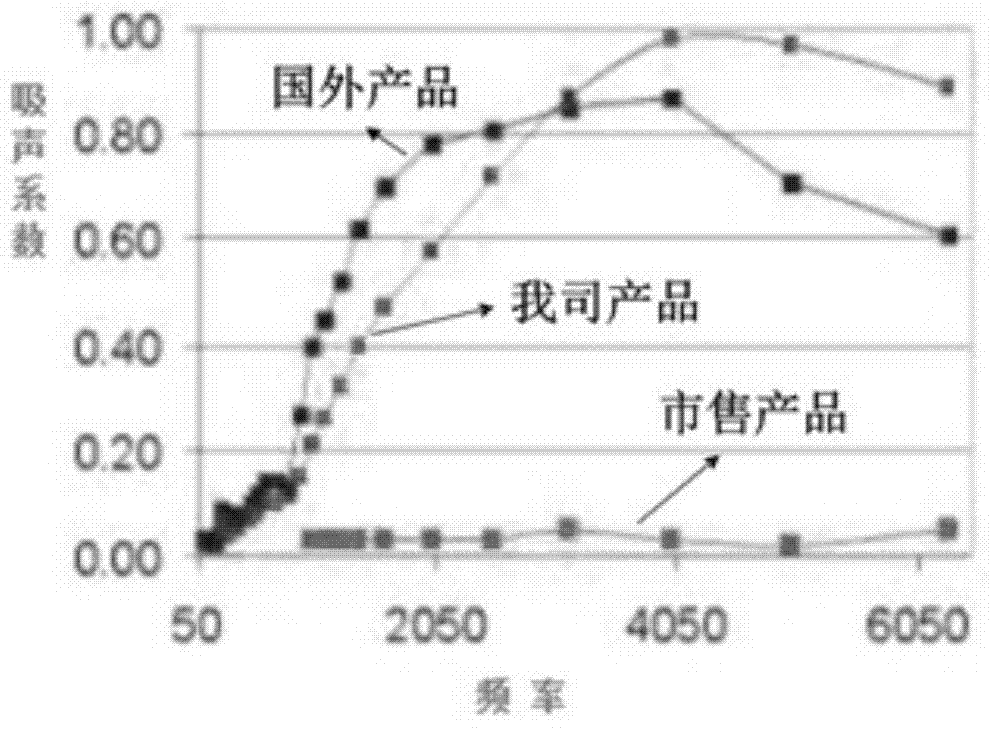

A technology for reinforcing thermoplastic and lightweight fibers, applied in the field of composite materials for automotive exterior parts, can solve the problems of less attention to the material selection, design and processing technology of the bottom guard plate, and achieve the effect of optimizing production efficiency and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

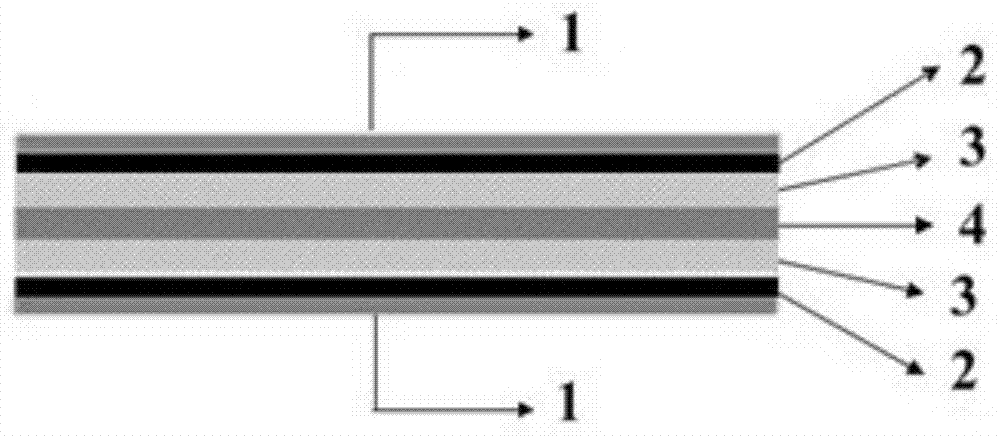

[0027] (1) After the polypropylene fiber with a mass fraction of 65% and the glass fiber with a mass fraction of 20% are loosened by an opener, they are then cross-laid, and 5%, 50-mesh polyethylene rubber powder and 200-mesh, 10% aluminum hydroxide powder, followed by infrared baking at 140°C, and needle punching with tapered needles, needle depth 7mm, and needle density 45, to obtain a fiber-reinforced thermoplastic felt for the impact-resistant flame-retardant layer 3. Combining the composition design and acupuncture process, the layer has good impact resistance, and the modified aluminum hydroxide particles are evenly dispersed in the material, which can absorb heat and decompose to generate water during the combustion process, thereby achieving the effect of flame retardancy. Therefore, this layer has both the functions of impact resistance and flame retardancy.

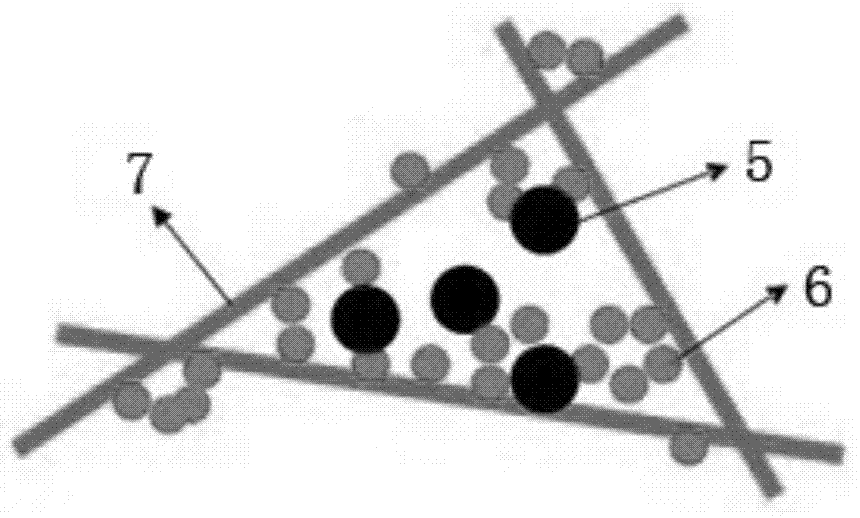

[0028] (2) After the polypropylene fiber with a mass fraction of 45% and the reinforcing fiber 7 with a mass ...

Embodiment 2

[0035] (1) Open the polypropylene fiber with a mass fraction of 55% and 30% (glass fiber + basalt fiber) by an opener, then cross-laminate, and add 6% polypropylene glue of 200 mesh through a powder spreader Powder and 400 mesh, 9% modified magnesium hydroxide powder, followed by infrared baking at 140 ° C, and needle punching with tapered needles, needle depth 5 mm, needle density 80, to obtain the impact flame retardant layer 3 Fiber reinforced thermoplastic felt.

[0036] (2) After the polypropylene fiber with a mass fraction of 45% and the reinforcing fiber with a mass fraction of 50% are opened by a fiber opener, then cross-laminated, and 10%, 150 mesh and 50 mesh polypropylene rubber powder are added through a powder spreader, Then infrared baking was carried out at 140° C., and needle punching was carried out with circular needles with a needle depth of 10 mm and a needle density of 40 to obtain a fiber-reinforced thermoplastic felt for the anti-sound-absorbing layer 4 ...

Embodiment 3

[0039] (1) After the mass fraction of 50% (polypropylene fiber + nylon fiber) and 30% of the glass fiber are loosened by the opener, then cross-laminated, and 10% of the 100-mesh polyethylene glue is added through the powder spreader powder and 300 mesh, 10% expanded graphite powder, followed by infrared baking at 140°C, and needle punching with triangular needles, needle depth 9mm, and needle density 66, to obtain a fiber-reinforced thermoplastic felt for the impact-resistant flame-retardant layer 3 .

[0040] (2) After the polypropylene fiber with a mass fraction of 45% and the reinforcing fiber with a mass fraction of 50% are opened by a fiber opener, then cross-laid, and 10%, 150 mesh and 50 mesh polyethylene rubber powder are added through a powder spreader, Then infrared baking was carried out at 140° C., and needle punching was carried out with tapered needles, the needle depth was 7 mm, and the needle density was 70, to obtain the fiber-reinforced thermoplastic felt of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com