Leadless ceramic chip carrier packaging structure and process for manufacturing same

A technology of packaging structure and ceramic sheet, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of easy lack of ceramics in semi-circular holes, low yield, reduced pad pitch, etc., to eliminate Soldering short-circuit problem, easy and thorough cleaning, and the effect of improving the production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

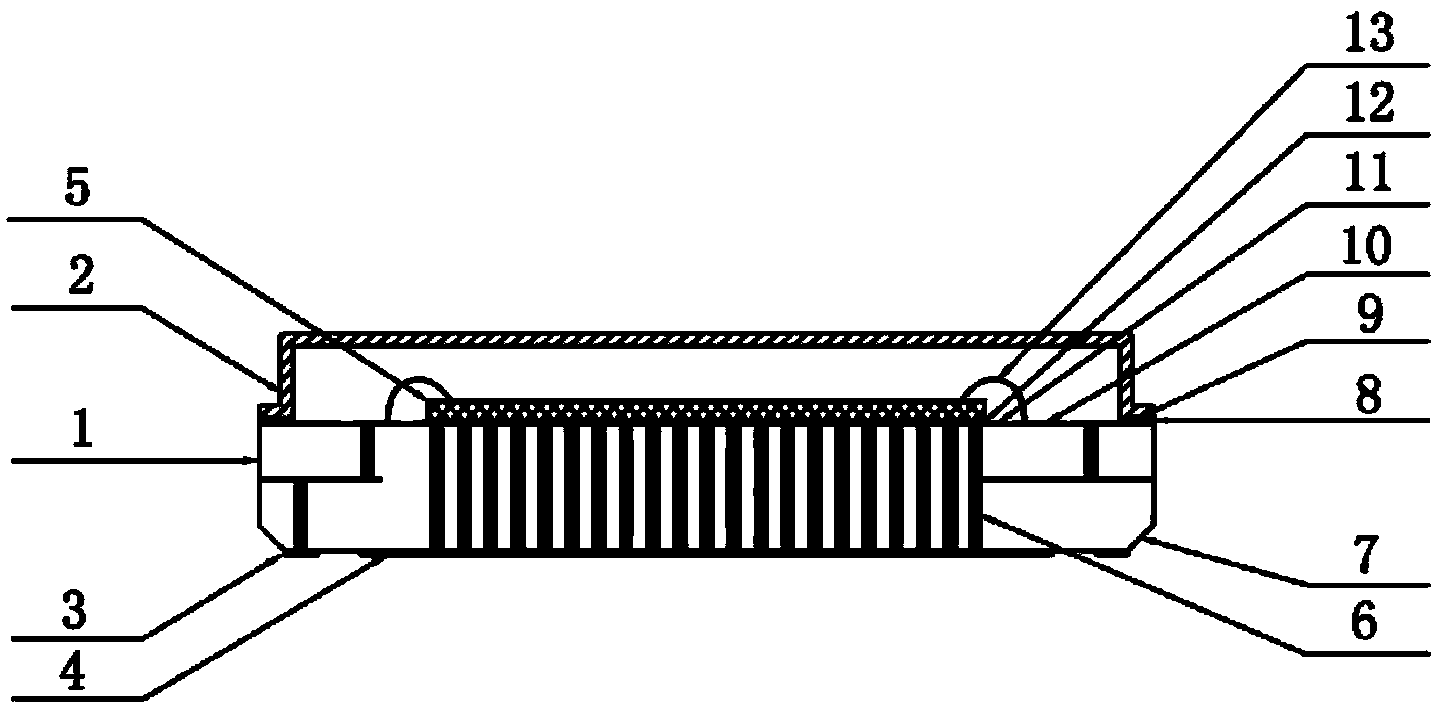

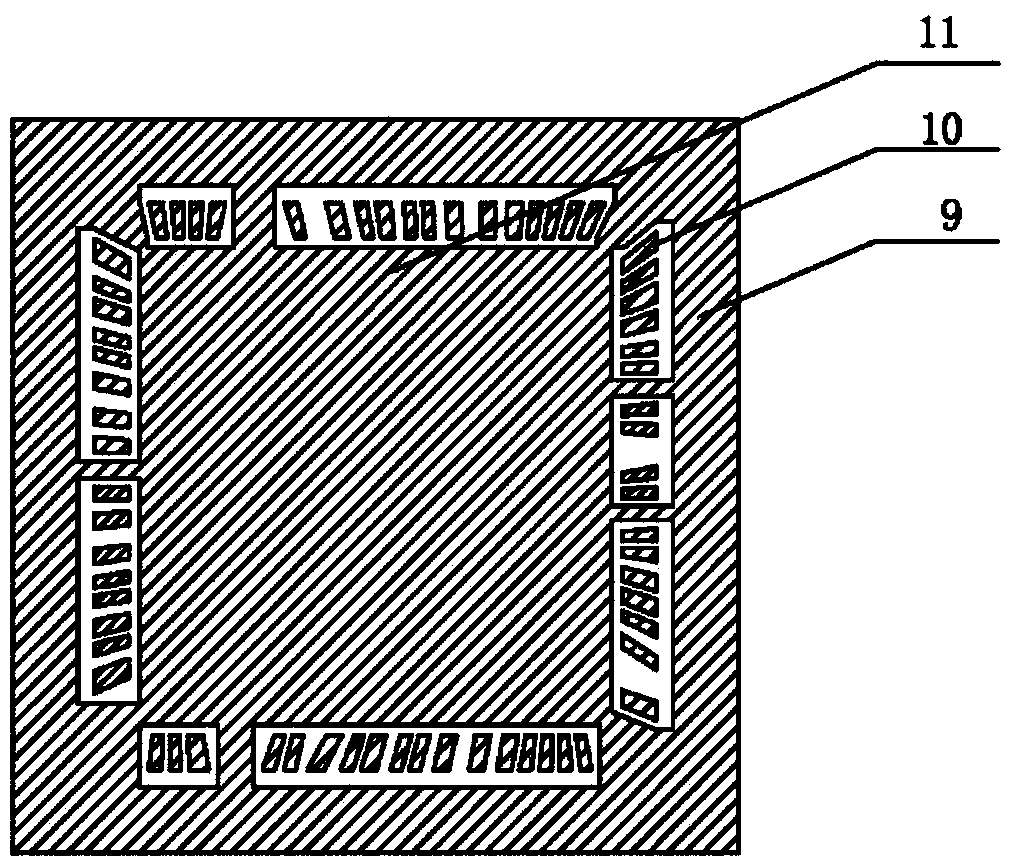

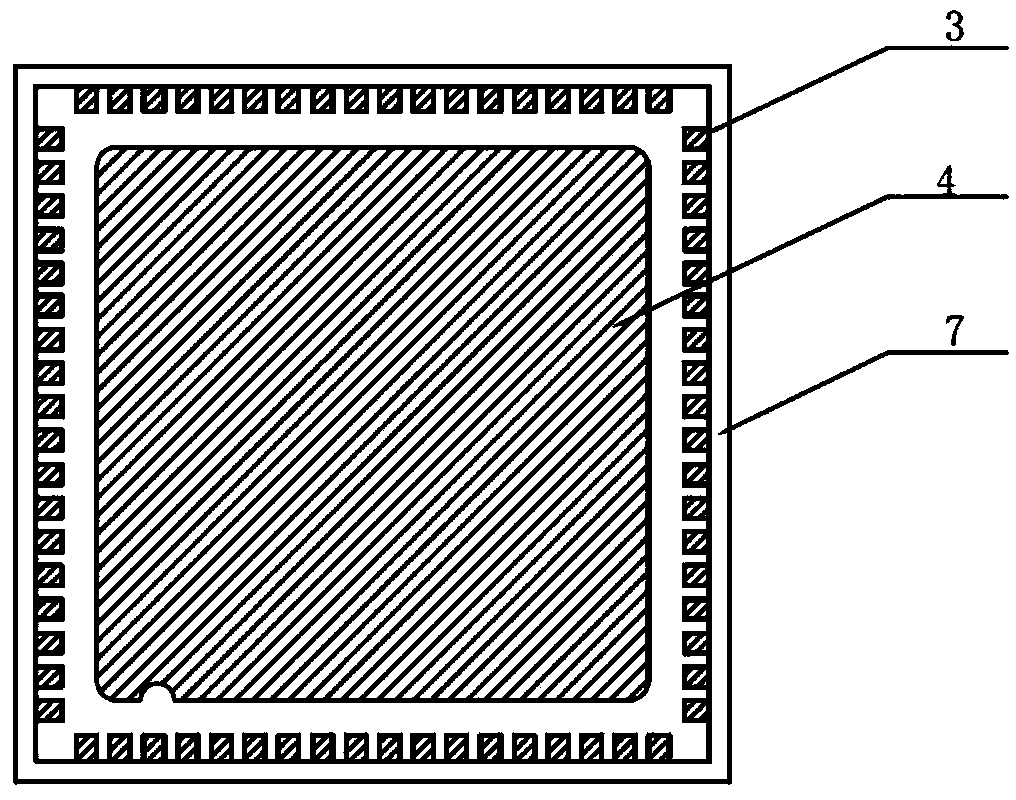

[0022] Such as figure 1 Shown is a schematic structural view of the leadless ceramic chip carrier package of the present invention, which includes a shell 1 and a cover plate 2 , and the cover plate 2 covers the shell 1 . The housing 1 is a multilayer ceramic board, the upper surface of the multilayer ceramic board is provided with a chip bonding area 11 in the center, and a wire bonding area 10 is provided around the chip bonding area 11, and a sealing area 9 is provided around the wire bonding area 10 . Wherein, the sealing area 9 , the wire bonding area 10 , and the chip bonding area 11 are coplanarly arranged. A welding pad 4 is provided at the center of the lower surface of the multilayer ceramic board, and a terminal pad 3 is provided around the pad 4 , and the terminal pad 3 is connected to the wire bonding area 10 . A number of metal via holes 6 are vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com