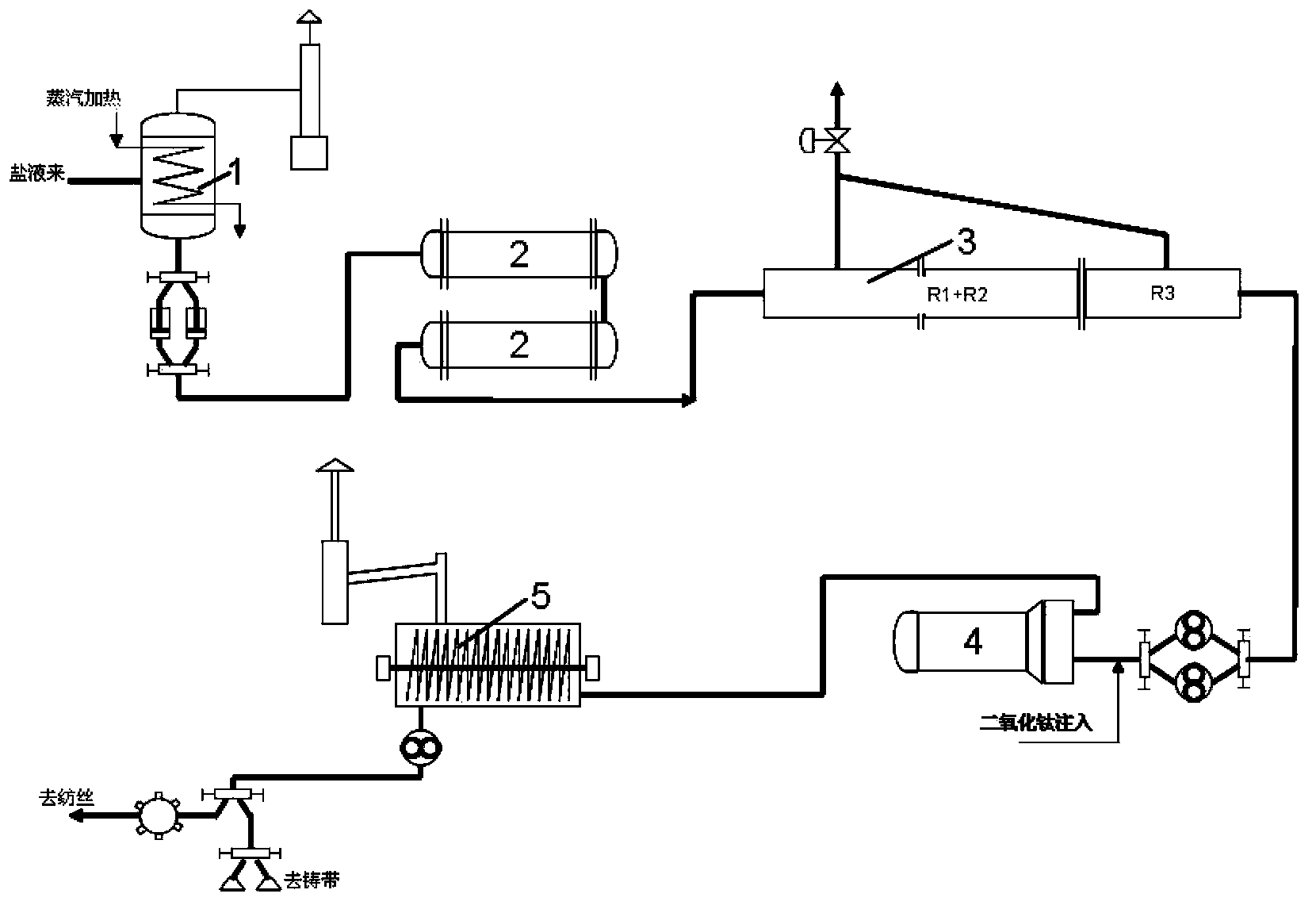

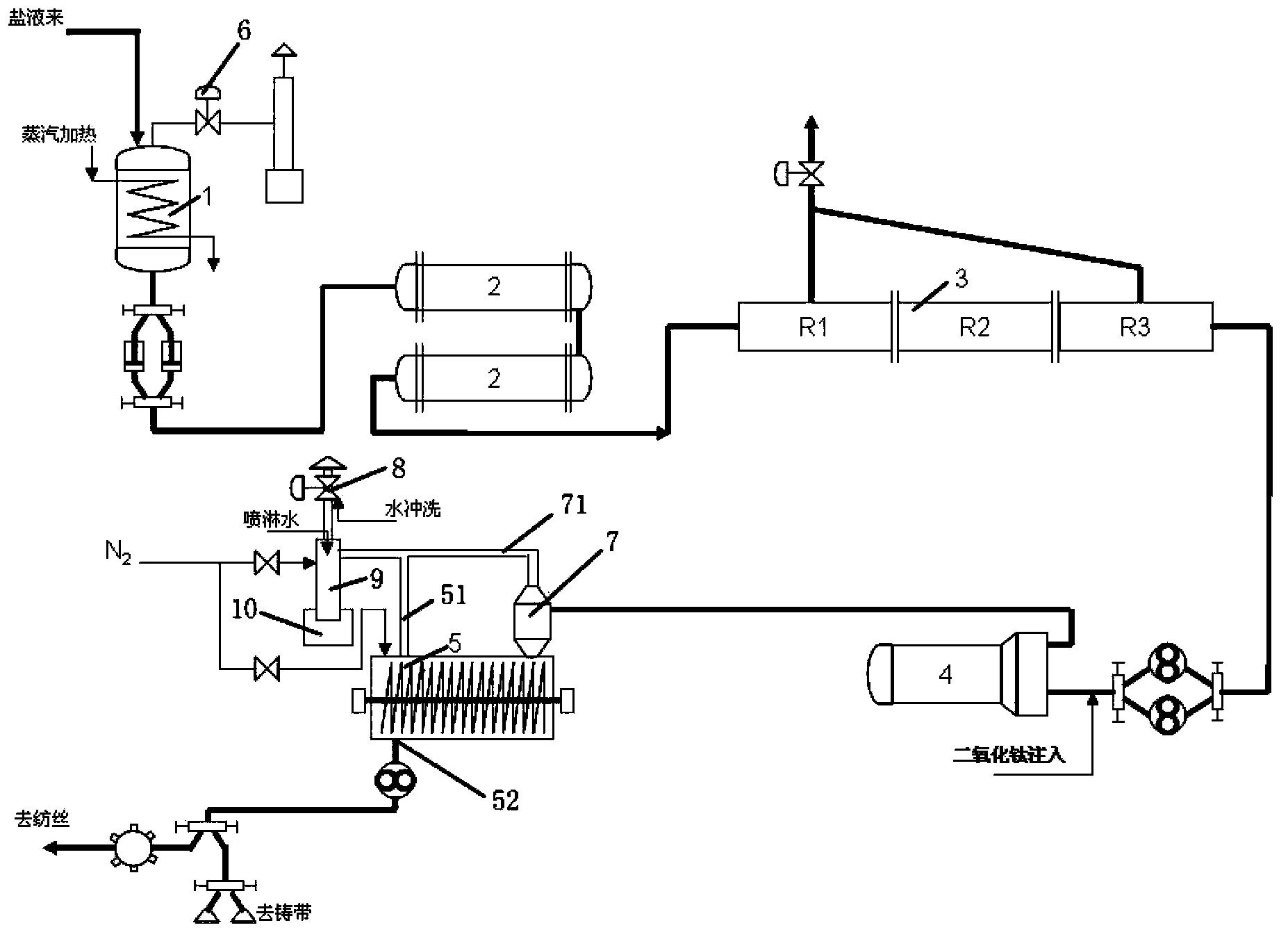

Device and method for producing fine-denier or super-fine-denier nylon 66 filament

A technology of ultra-fine denier and nylon, applied in the field of textile materials, can solve the problems of different definitions, fine denier, and micro-denier fibers without uniform caliber standards, etc., and achieve the effect of broad application and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Using the above-mentioned improved horizontal tubular continuous polycondensation system to produce fine denier or ultrafine denier nylon 66 filaments, the aqueous solution of nylon 66 salt (with a concentration of 50% by mass) is subjected to polycondensation reaction through the continuous polycondensation system to obtain nylon 66 Resin melt, and then the nylon 66 resin melt is directly spun to prepare fine denier or ultra-fine denier nylon 66 POY filament; during the spinning process, the temperature of the spinning box is 286°C, the temperature control accuracy is ±0.2°C, and the initial pressure of the component 20-22MPa.

[0046] Spinneret is the plate diameter The aperture is 0.3mm, and the length-to-diameter ratio is 4:1 parallel spinneret. The filter material of the spinning assembly is P-270 stainless steel metal sand.

[0047] Side blowing air temperature is 22°C, wind speed is 0.75m / s, rheumatism is 75%, oiling concentration is 8%, oiling rate is 0.45%, o...

Embodiment 2

[0053] The difference from Example 1 is that the aqueous solution of nylon 66 salt has a mass percentage concentration of 55%. During the spinning process, the temperature of the spinning box is 290° C., the aperture of the spinneret is 0.4 mm, and the filter material of the spinning assembly is P -271 stainless steel metal grit.

[0054] The air temperature of side blowing is 22°C, the wind speed is 0.8m / s, the rheumatism is 85%, and the oiling concentration is 12%.

[0055] Control the POY network degree to 8 pieces / m, and the winding speed to 4300m / min.

[0056] The prepared product specification of present embodiment is as follows:

[0057] Fiber specification: 64dtex / 68f superfine denier PA66.

[0058] Fiber quality indicators: strength 35.27CN / tex; elongation 24.05%; crimp shrinkage 40.26%; crimp stability 49.26%; oil content 3.31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com