A Grabbing Manipulator for Plastic Injection Parts

A grabbing manipulator and grabbing mechanism technology, applied in the field of grabbing manipulators, can solve the problems that the quality of parts should not be too large, not suitable for the use of injection molding machines, and hinder the health of workers, so as to reduce the scrap rate, have a simple structure, and take up space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

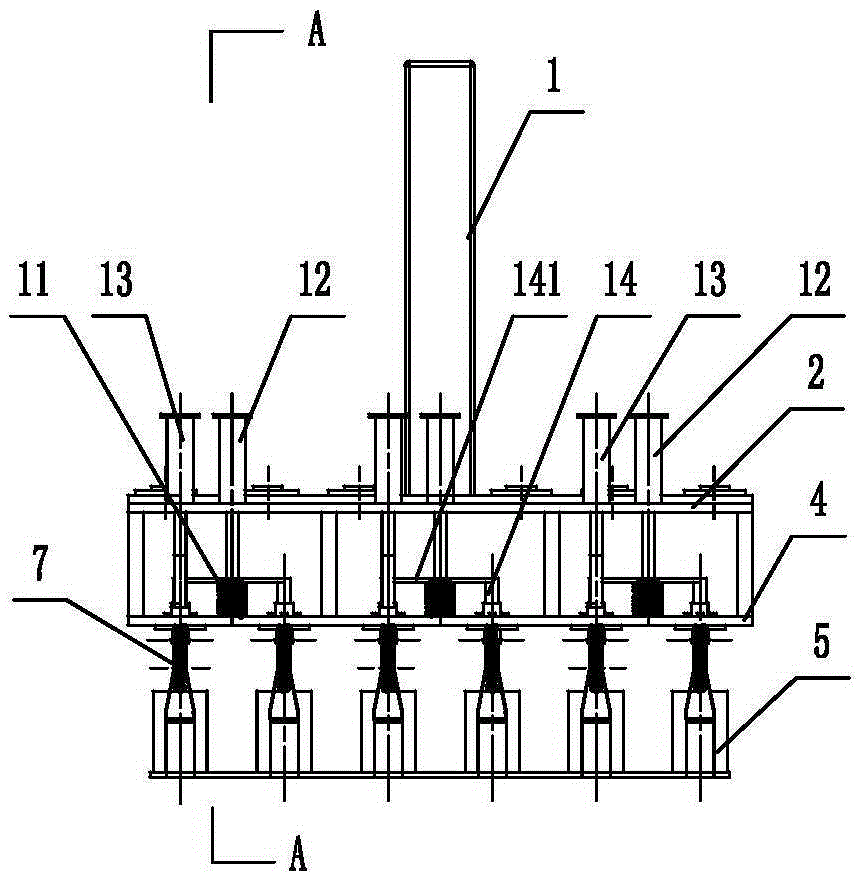

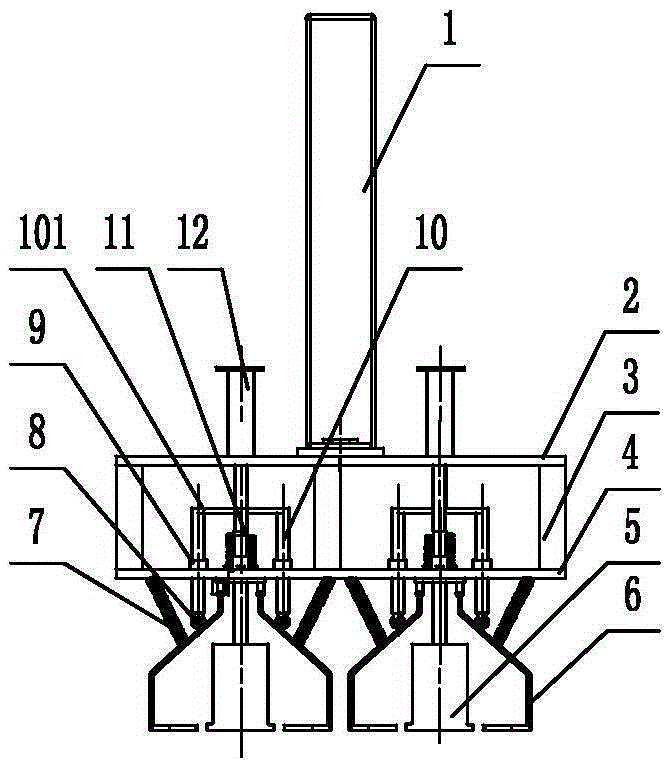

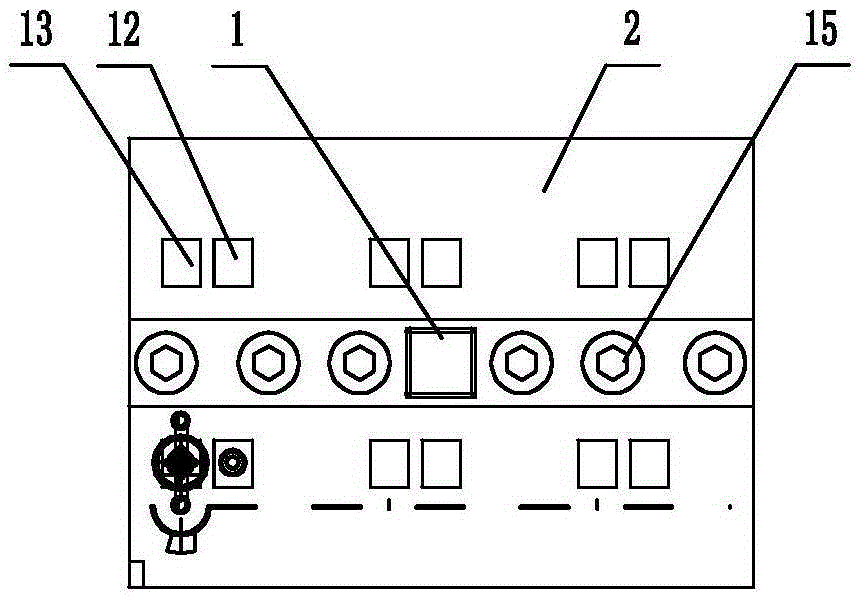

[0030] A gripping manipulator for glue injection parts, including a bracket, and 6 sets of gripping mechanisms and blowing mechanisms installed on the bracket. The bracket is composed of an upper support plate 2 and a lower support plate 4. The upper support plate It is integrated with the lower support plate through the support column 3, and the upper support plate is connected with the main rod 1 through the bolt 15;

[0031] Described each group grabbing mechanism comprises two pairs of clamps 6 and front and rear clamp push rod 10 and clamp cylinder 13 that are connected as a whole, and described clamps comprises identical structure, front and rear two clamp arms 61 and front and rear clamp arms 61 that are installed opposite to each other. The back two grippers 62, the front and rear grippers are installed in a "eight" shape, the upper end of the gripper arm is hinged with the connecting bracket 16 at the bottom of the lower support plate 4, and the lower end of the grippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com