Bacillus coagulans strain and integrated process for producing lactic acid by using same through synchronous saccharification and fermentation of lignocellulose

A technology of bacillus coagulans and lignocellulose, which is applied in the fields of fermentation, chemical industry, and microbial-based methods, etc., can solve the problems of industrial application limitations, increase in fermentation process costs, etc., achieve strong inhibitor tolerance and avoid extensive washing Water demand, effects of avoiding energy losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

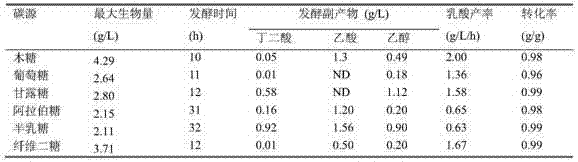

[0024] Isolation and identification of Bacillus coagulans CGMCC No. 7635 and its fermentation performance

[0025] The medium used in this experiment is as follows:

[0026] MRS medium: tryptone 10g / L, beef powder 10g / L, yeast powder 5g / L, anhydrous sodium acetate 5g / L, hydrogen citrate diamine 2g / L, dipotassium hydrogen phosphate 2g / L, sulfuric acid heptahydrate Magnesium 0.2g / L, manganese sulfate monohydrate 0.05g / L. Solid medium, 1.5% agar powder is added to MRS medium, 2% glucose or xylose is added as needed; Screening medium, solid medium is added 0.015% bromocresol purple; Seed medium: peptone 10g / L, yeast Powder 5g / L, glucose 10g / L, the balance is water. Fermentation medium: tryptone 10g / L, yeast powder 5g / L, carbon source is different according to different experiments, specifically one of glucose, xylose, mannose, arabinose, galactose or cellobiose, carbon source concentration It is 20g / L, and the balance is water.

[0027] Fermentation method: inoculate the colony cultu...

Embodiment 2

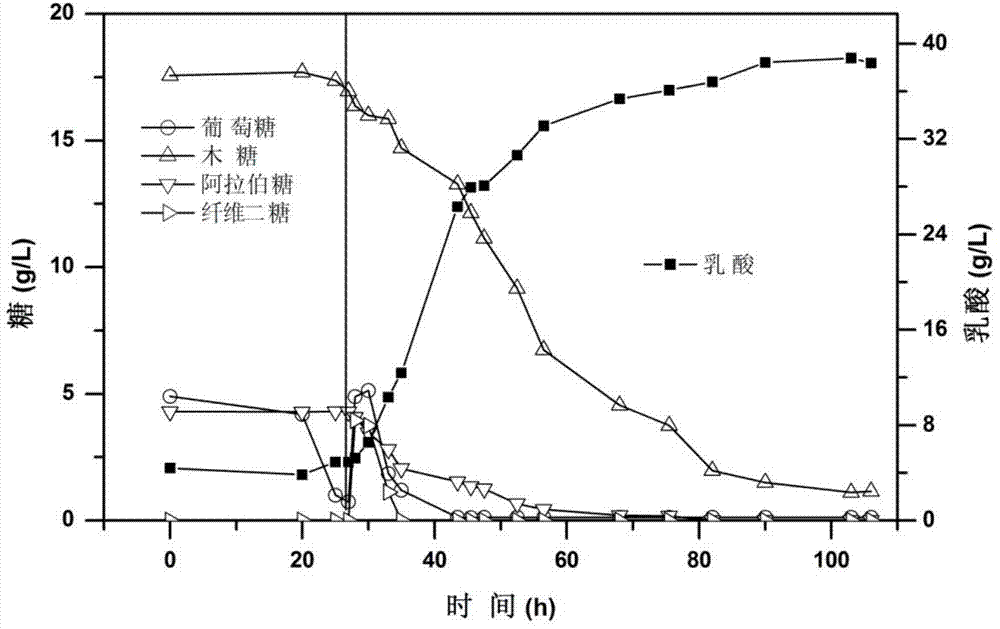

[0037] Bacillus coagulans (Bacillus coagulans) CGMCC No.7635 simultaneous saccharification and co-fermentation of wheat straw integrated process for producing lactic acid

[0038] The wheat straw is washed, dried, and crushed into powder with an average size of 40 mesh. Take 100g of dry weight wheat straw powder and treat it with 2% (w / v) sulfuric acid at 121°C for 90 minutes in a fermenter, with a solid-liquid ratio of 1:10 (mass volume ratio). After pretreatment, after adjusting the pH to 6.0 with sodium hydroxide, 10g / L dry corn steep powder was added, and the prepared Bacillus coagulans CGMCC No. 7635 secondary seed solution (the preparation method is the same as in Example 1) A 5% (v / v) inoculum was inoculated into the wheat straw pretreatment liquid obtained above, and the integrated process of simultaneous saccharification and co-fermentation was started. The fermentation process is divided into phase I and phase II. The stage I culture conditions are: 300 rpm, 55°C, and...

Embodiment 3

[0040] Integrated process for simultaneous saccharification and co-fermentation of corn stover to produce lactic acid from Bacillus coagulans CGMCC No.7635

[0041] The corn stalks are washed, dried, crushed into powder with an average size of 40 meshes, and pretreated by steam explosion with ammonia. The corn stalk powder is treated by ammonia steam explosion. The steam explosion operation conditions are: pressure 1.5MPa, maintenance for 10 minutes, solid-liquid ratio 1:8 (mass volume ratio), and ammonia water consumption is 5%. After pretreatment, use sulfuric acid to adjust the pH to 7.5, then add 10g / L corn steep liquor, and prepare the Bacillus coagulans CGMCC No. 7635 secondary seeds (the preparation method is the same as in Example 1) with 5% (V / v) The amount of inoculum inoculation begins to ferment. The fermentation process is divided into phase I and phase II. The stage I culture conditions are: 300 rpm, 58°C, and the pH is temporarily not controlled. As the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com