Method with heat integration function for separating ethylene glycol from 1,2-butylene glycol

A technology of ethylene glycol and butanediol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of high energy consumption in the separation process, reduce the number of theoretical plates, increase work efficiency, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

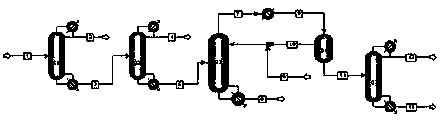

[0038] use figure 2 In the first kind of heat integration process flow shown, the operating conditions of raw material stream 1, each tower and phase separator are the same as in Example 1, and the purity of ethylene glycol after refining, the value of ultraviolet transmittance and the recovery rate are basically unchanged, and the process The total energy consumption is reduced to 3.113×10 3 KJ / (kg×hour), which is 17.91% lower than the energy consumption of the common four-tower separation process.

[0039]

Embodiment 2

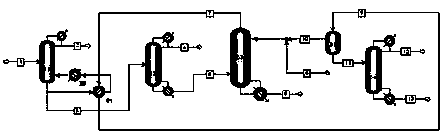

[0041] use image 3 In the second heat integration process shown, the operating conditions of raw material stream 1, each tower and phase separator are the same as in Example 1, and the purity of ethylene glycol after refining, the UV transmittance value and the recovery rate are basically unchanged, and the process The total energy consumption is reduced to 3.052×10 3 KJ / (kg×hour), which is 19.51% lower than the energy consumption of ordinary four-tower separation process.

[0042]

Embodiment 3

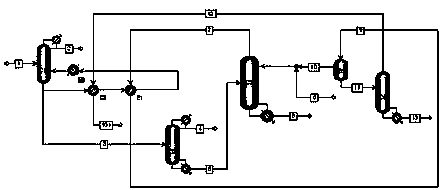

[0044] use Figure 4 As shown in the third heat integration process flow, the operating conditions of raw material stream 1, each tower and phase separator are the same as in Example 1, and the purity of ethylene glycol after refining, the UV transmittance value and the recovery rate are basically unchanged, and the process The total energy consumption is reduced to 3.059×10 3 KJ / (kg×hour), which is 19.33% lower than the energy consumption of the common four-tower separation process.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com