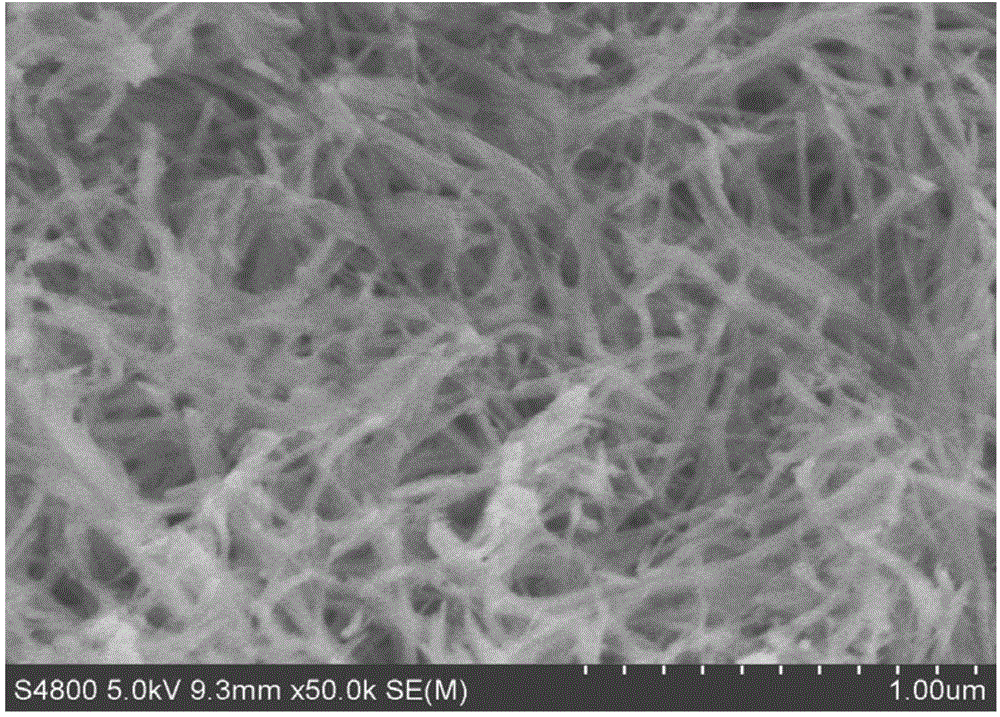

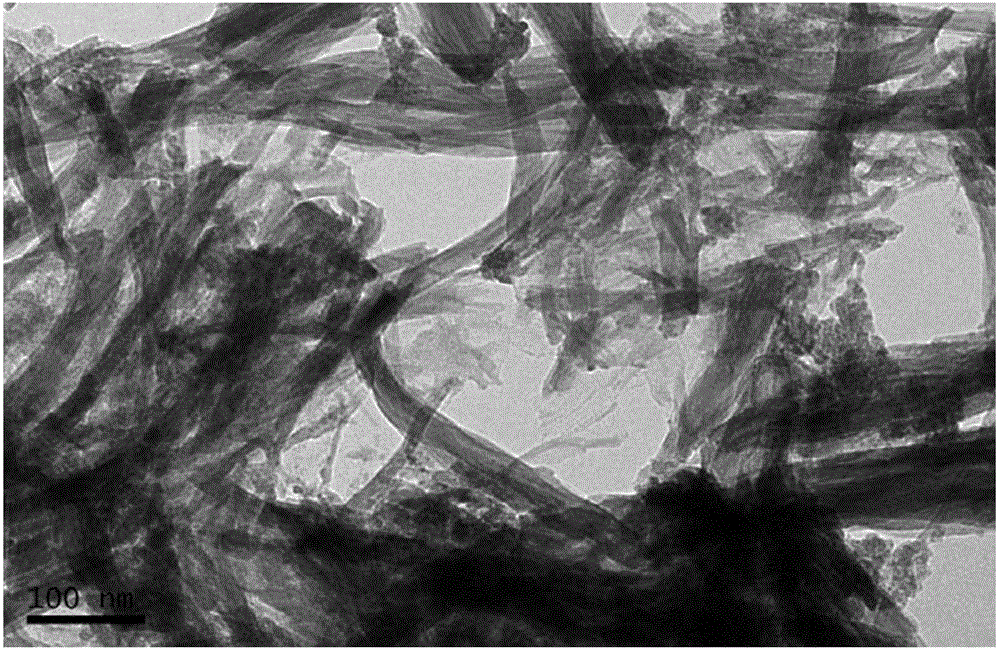

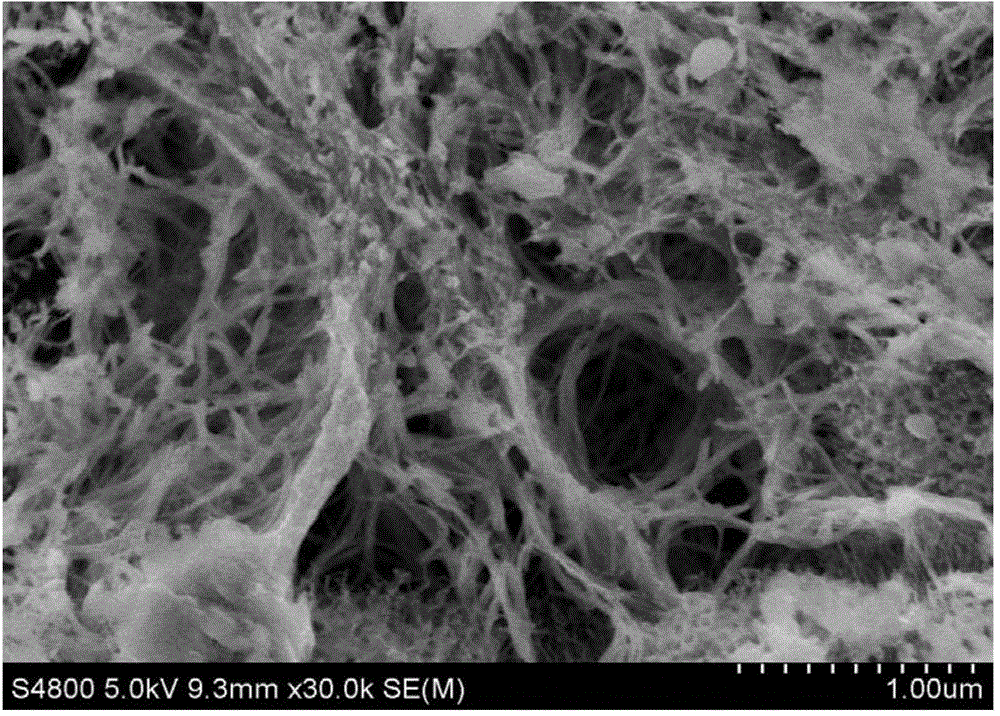

Preparation method of visible light catalysis material for graphene/bismuth molybdate nanobelt

A catalytic material, graphene technology, applied in the field of photocatalytic materials, can solve the problems of limiting the application of bismuth molybdate, unfavorable large-scale production, low photocatalytic efficiency, etc., and achieves good electron transport performance, low processing temperature, and photocatalysis. Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Add 4 mL of graphene oxide solution with a concentration of 0.9 g / L into 50 mL of deionized water and ultrasonically disperse for 30 min to obtain a graphene dispersion;

[0033] (2) Add 0.8 g sodium polyacrylate to the graphene dispersion, stir and ultrasonically disperse at 25°C for 20 min to obtain a uniformly dispersed solution;

[0034] (3) Add 0.6 g of sodium molybdate to the uniformly dispersed solution, and continue ultrasonic dispersion at 10°C for 20 min to obtain a uniformly dispersed solution;

[0035] (4) Slowly drop 10 mL of bismuth nitrate solution with a concentration of 0.103 mol / L into the uniformly dispersed solution, and ultrasonically stir for 20 min to obtain a uniformly dispersed colloidal liquid;

[0036] (5) Add 0.1 g of gelatin to the uniformly dispersed colloidal liquid, stir ultrasonically for 30 min, and place it at 50°C for 5 h to obtain a uniformly dispersed viscous liquid;

[0037] (6) Add 20 mL of ammonia solution with a concentratio...

Embodiment 2

[0042] (1) Add 13 mL of reduced graphene oxide solution with a concentration of 1.2 g / L into 50 mL of deionized water and ultrasonically disperse for 40 min to obtain a graphene dispersion;

[0043] (2) Add 1.8 g of sodium alginate to the graphene dispersion, stir and ultrasonically disperse at 35 °C for 30 min to obtain a uniformly dispersed solution;

[0044] (3) Add 1.8 g of ammonium molybdate to the uniformly dispersed solution, and continue to ultrasonically disperse for 30 min at 35 °C to obtain a uniformly dispersed solution;

[0045] (4) Slowly drop 16 mL of bismuth nitrate solution with a concentration of 0.13 mol / L into the uniformly dispersed solution, and ultrasonically stir for 30 min to obtain a uniformly dispersed colloidal liquid;

[0046] (5) Add 1.6 g of gelatin to the uniformly dispersed colloidal liquid, stir ultrasonically for 30 min, and place it at 50°C for 7 h to obtain a uniformly dispersed viscous liquid;

[0047] (6) Add 20 mL of NaOH solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com